Ultra-High Accuracy CNC Coordinate Measuring Machine

The LEGEX 4 CNC CMM from Mitutoyo can measure ultra-precise molds, aspherical lenses and parts for medical instruments, and calibrate master gages for research institutes.

Posted: August 30, 2016

Mitutoyo America Corporation (Aurora, IL) offers the ultra-accurate LEGEX 4 CNC coordinate measuring machine (CMM) that surpasses conventional CMM performance to deliver world-leading accuracy in length measurement of E0,MPE = (0.28+L/1000) μm. With the unceasing advancement of scientific and industrial technologies and driving demand for significant improvements in high-accuracy manufacturing, the LEGEX meets the needs of a growing number of manufacturers with applications such as ultra-precise molds, components and aspherical lenses in the medical instrument industry, and calibration of master gages for research institutes. To meet these increasing needs, Mitutoyo took a fresh approach when it came to accuracy, starting from the elemental technology level and working upward, with the aim of eliminating all possible sources of measurement error.

Key features of the LEGEX 4 CNC coordinate measuring machine include:

- Sources of static and dynamic error minimized to realize world-leading measurement accuracy of 0.28 μm.

- Fixed-bridge structure with moving table.

- Base is made from spheroidal graphite (ductile) cast iron in a sealed-structure design to provide high rigidity and vibration-attenuating characteristics.

- High-rigidity structure and feed mechanisms increase accuracy and improve cycle times.

- Thermally symmetric structure features full covers around the main body to reduce possible impact in ambient temperature changes.

- Vibration-dampening unit is standard.

- An air server stabilizes the air temperature to 20 deg C ±0.1 deg C.

- Newest CMM realizes world-leading measurement accuracy of 0.28 μm.

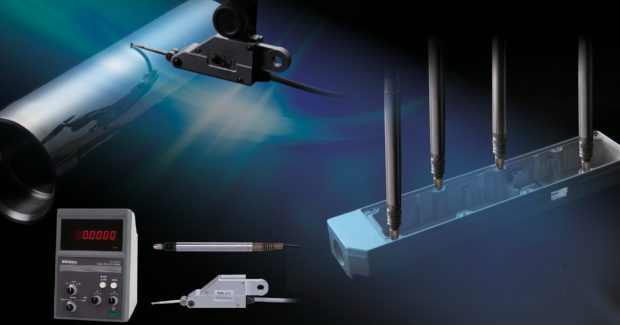

Mitutoyo has also introduced their 519 Series of high-accuracy Mu-Checker probes and displays. These electronic gaging systems are suitable for a range of applications from the inspection room to production-line integration. High-resolution lever-head probes allow multi-point measurements of small parts, flatness and straightness measurement on X/Y table, as well as runout measurement of shafts. The cartridge-head type is easily built into equipment due to its slim and compact shape, making it optimal for an automatic measuring machine. Probes are offered with a standard measuring force of 0.2 N, or a low measuring force of 0.02 N. The low-force style enables soft workpieces to be measured without significant deformation. Optional styli, extension rods and brackets are available. Both digital and analog display models offer zero setting with the touch of a button. Additional models allow for multi-probe measuring systems.

Mitutoyo America Corporation, 965 Corporate Boulevard, Aurora, IL 60502, 888-648-8869, www.mitutoyo.com.