Speed and Precision in Chemical Plant Engineering

With investments in chemical plants expected to double over the next few years, here are some insights into selecting the right machines to efficiently manufacture enormous quantities of quality double-walled tubes from high-strength special materials that are often flanged and beaded.

Posted: August 25, 2016

The American Chemistry Council (ACC; Washington, DC) forecasts that, within the next eight years, investments in chemical plants will double worldwide due to global megatrends in population growth, emerging markets and the appetite for raw materials. This increases the necessity for chemical plant designers to demand more machines that can efficiently manufacture enormous quantities of quality tubes. This is not an easy task, because the high-strength special materials – which are often flanged, beaded or double-walled tubes – require a demanding process. Two different production methods are used to manufacture tube systems for chemical plants: welding of bent tube components or production of complex tube systems using bending technology.

To fabricate tubing systems, many manufacturers commonly use welding procedures that connect straight tube sections with weld-in elbows. This procedure is very labor intensive. First, the individual tube components must be welded. Then each individual weld joint is subject to a costly inspection method that must guarantee the air tightness of the line. Considering the multitude of connecting points, this is a very time consuming procedure that may still contain the potential of making errors. Cold bending reduces the required work to a minimum by using bending machines that can form complex tubing systems from a single piece of blank. However, not every bending machine can guarantee compliance with the high demands that the chemical industry places on the forming process.

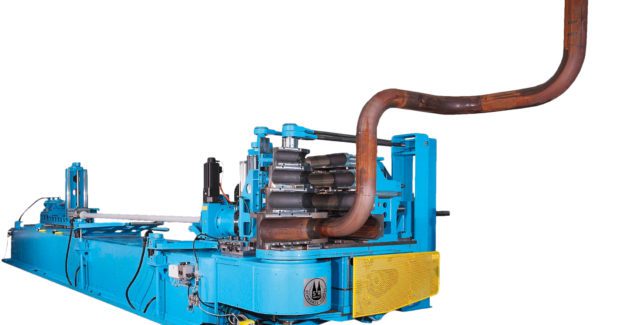

When selecting the right machine, one must verify that the bender is designed for bending stainless steel tubes and that it ensures absolute minimum ovality when forming the tube. Ovality is an important requirement for all tubes carrying chemical substances because these tubes are eventually cleaned using a spherical object that is slightly narrower in the center that is referred to as a “PIG” (Pipeline Inspection Gauge). Excessive ovality in these so-called PIG tubes can lead to chemical residues that become mixed in the next production loop. Heavy duty automatic CNC bending machines are optimized precisely to meet the requirements of the chemical industry. They produce three-dimensional tube systems rapidly and exactly. The tube is clamped into the index head and positioned in the space by means of the transport unit and index head. After the first bend, it is directly pushed on and rotated, if required, producing 3D tube systems with minimum ovality that fit precisely.

When the speedy manufacture of different types of tubes is important, CNC tube bending machines with multi-stack bending tools are a wise choice because they process tubes with different nominal diameters on a single system without retrofitting efforts. They can bend tubes with a maximum diameter of 219.1 mm x 12.7 mm and a tube length of up to five meters. With the help of the multi-stack bending tool, up to 70 percent of the setup time of market-based systems can be saved. It is possible to process tubes of different materials, such as steel, nickel alloys, iron and stainless steel on one tool.

Other time-saving technologies are available for forming double-walled tubes and flanged tubes. Flanged tube equipment takes the flange and sleeve positions into consideration before the bending process starts to omit the time-consuming adding of subsequent flanges necessary to finished tube bends. The tubes can be implemented into existing systems after the bending process is completed. Another time saver is marking devices that indicate the positions on the tubes where welds or bypasses are to be made after bending.

Long pipelines made of high quality materials create considerable costs and quite often must be integrated in a space-saving manner. One option here are small bending radii that optimize tube runs enormously if space is limited and reduce the usage of material. There are tube benders that can produce extremely small bending radii of 1.5 x tube diameter. This also applies to large, very thin-walled tubes with a diameter of up to 323.9 mm and a length of six meters. Similarly tight radii with such large tubes are usually achieved only with much slower and more expensive warm bending processes or welding elbows. Semi-automatic tube bending machines are perfectly suited for producing individual bends and small production runs. They must be very rugged machines with extremely high structural rigidity to withstand enormous bending forces. Based on the tremendous power reserves of their clamping forces, these machines can produce optimum bending results.