Miniature Incremental Optical Encoder for Inspection and Metrology

The ATOM non-contact optical linear and rotary incremental encoder system from Renishaw delivers unrivaled metrology performance and class-leading accuracy, with low Sub-Divisional Error (SDE), low jitter and long-term reliability.

Posted: August 30, 2016

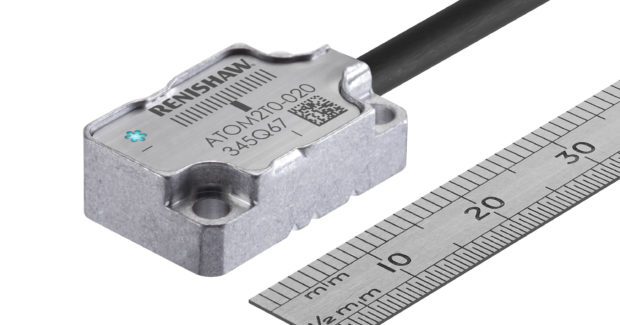

Renishaw, Inc. (Hoffman Estates, IL) offers their ATOM™ non-contact optical linear and rotary incremental encoder system that combines miniaturization with leading-edge dirt immunity, signal stability and reliability. With a readhead as small as 6.7 mm x 12.7 mm x 20.5 mm, ATOM is the first miniature encoder to use filtering optics with Auto Gain Control (AGC) and Auto Offset Control (AOC) for exceptional signal stability and dirt immunity that is ideal for medical applications, inspection and metrology. The system delivers unrivaled metrology performance and class-leading accuracy, with low Sub-Divisional Error (SDE), low jitter and long-term reliability.

ATOM offers analog speeds to 20 m/s (29,000 rpm on a 17 mm disc) and digital resolutions to 1 nm when used with Renishaw interpolation electronics. The readhead includes a set-up LED to allow quick and easy installation, and an auto-calibration routine to enable faster optimization. Scale options include linear and rotary (angle) scales in stainless steel and glass. The ultra-compact readhead is available with either high-flex cable or Flexible-Printed Circuit (FPC) output, in both 20 µm and 40 µm scale options, with ultra-compact interface electronics in ACi and Ri options. The FPC variant reduces the overall package size and allows integration with ACi. A variety of high-accuracy scales is available, including industry-standard stainless steel tapes, high accuracy linear glass spars and rotary glass discs from 17 mm to 108 mm diameter.

Optional interfaces support interpolation factors to x 20,000, allowing outstanding metrology and unmatched dynamic performance. Designers can also use the sinusoidal signal output from the readhead for direct connection to analog drives and controllers. ATOM is CE-approved and manufactured in-house at Renishaw under strict quality controls certified to ISO 9001:2008. Advanced, automated manufacturing processes minimize process variability to ensure high quality, short lead times and competitive pricing. The system is backed by Renishaw’s global sales and support network.

Renishaw Inc., 5277 Trillium Boulevard, Hoffman Estates, IL 60192, 847-286-9953, Fax: 847-286-9974, www.renishaw.com/machinetool.