Medical Machining: Machine Tools

Take a closer look at some of the newest equipment that can help contract manufacturers meet the machining, micro machining, and laser processing demands for smaller and more complex surgical implants, orthotic devices and medical instruments that are being made from newer materials – and still hold their costs down.

Posted: August 29, 2016

The $148 billion medical device market in the United States is the largest in the world and is expected to grow to $155 billion by 2017. Demand is high for contract manufacturers that can meet the machining, micro machining, and laser processing demands for smaller and more complex surgical implants, orthotic devices and medical instruments that are being made from newer materials. To help OEMs save time and money and get medical devices into the marketplace faster, contract shops must be able to deliver very small burr-free features (<50 microns) with tolerances as tight as ±1.0 micron that require no secondary processing. Here is some of the newest equipment and tooling that is available to help these shops quickly deliver accurate, dependable components that meet all validation and verification requirements – and still hold their costs down.

Next Generation Small Part 5-Axis Medical Machining

The a51nx-5XU 5-axis horizontal machining center from Makino enables manufacturers of complex medical parts to obtain the highest levels of utilization and efficiency.

Lathe Cuts Production Time on Medical Parts with Improved Output and Profitability

The cutting-edge software on the SW-20 Swiss-type Automatic Lathe from Star CNC processes complex bone screws, implant and surgical instruments with exceptionally high speed, precision and quality.

Intelligent Multitasking Lathe For Process Intensive Medical Parts

The MULTUS U3000 general purpose, multitasking two-saddle CNC lathe from Okuma America reduces setup time, improves accuracy and keeps non-cutting time to a minimum.

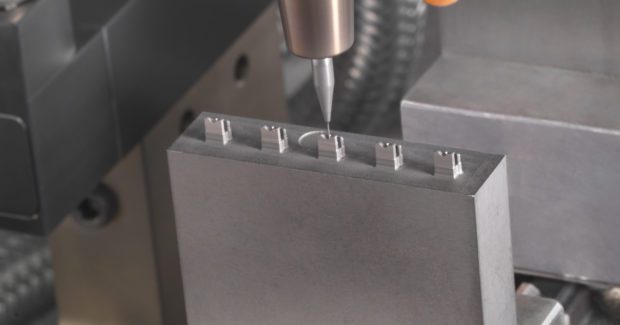

Precision Machining of Spherical Medical Components

The Sphero from Thielenhaus Microfinish is ideal for absolutely reliable machining of the entire outer surfaces of spheres and the inner surfaces of cups.

Radius Internal Cylindrical Grinding of Complex Medical Parts and Implants

Studer S121, S131 and S141 internal cylindrical grinding machines from United Grinding extend part production capabilities by offering more advanced technology, a new dressing concept and larger size machine to handle a broader range of workpieces.

High Performance, High Productivity Wire EDM for Medical Machining

The AgieCharmilles CUT E 350 wire EDM from GF Machining Solutions has a large intuitive touchscreen HMI that features onboard Intelligent Collision Protection, built-in machining strategies and flexible job management.

Flexible Gear Cutting and Worm Milling for Medical Devices

The compact AF110 gear hobbing center from Affolter Technologies has improved rigidity that guarantees short cycle times and highest efficiency.

Efficient Cutting of Stents and Tubes

The second generation Sigma Laser Stent & Tube Cutter from Amada Miyachi is excellent for cutting nitinol, stainless steel, and cobalt chromium.

Multi-Diameter Stock Versatility for High Production of Medical Devices

The Multi Mini Rhinobar bar feeder from Lexair makes multi-diameter bar stock processing faster and easier with a feedtube cartridge that automatically centers and feeds three sizes of small-diameter bar stock to Swiss-style CNC screw machines and sliding-head lathes.