The Machine Tool Goes Digital

As digital and virtual simulation optimize its mechanical, control and networking capabilities, the machine tool of the future will be redefined as a functional node in the broader network of the Internet of Things.

Posted: August 25, 2016

Machine tools are becoming increasingly more precise, quicker and better . . . yet the basic principle of the metal cutting machine has really changed very little: several rotary and linear axes are still combined differently inside a closed housing, and most control units are still not readily accessible. But in the coming era of Industry 4.0 – which is actually only another term for “networking” – the functionality of the machine tool must be opened up. What will this functionality look like in the future? How must it change to become the machine tool of Industry 4.0?

Two aspects are crucial: digitalization or virtualization of (first) the machine tools themselves and (second) their networking capabilities. The design and engineering of the machine tools of the future will be substantially optimized through meaningful models of mechanical behavior (static, dynamic and thermal) and control technology behavior (the drive train or control models). These models will be developed through digital and virtual simulation of component behaviors assessed through process simulation to detect any and all challenges at an early stage. Networking will have more of an effect on the machine tool as it performs operations. Future machine tools must contain semantic interfaces that will provide high resolution process data for deeper analysis, if possible in real time, or be functionally integrated into networked systems. The Industry 4.0 machine tool is essentially another functional node in the broader network that is the Internet of Things.

What effect will increasing automation of processes, especially through robots, have on the design of this machine tool? Automated production cells already exist in tool construction and mold making, but these cells (robots, machine tools, bearings) have identified major challenges related to their ability to cost-effectively produce the small lots of different parts that are typical in small and medium-sized shops. Their processes often cannot come on stream in parallel with production time, or their expertise required to do this is not available. To date only been a few approaches have been able to define a functionally extensive interface between a machine tool and a robot that can be integrated into the CAD/CAM-NC chain or the RC chain.

This opportunity becomes very exciting when we consider flexible automation by means of collaborative robotics, where there is great potential for small and mid-sized shops running small lots of different parts. We are currently establishing a working party to examine this question both on the research side and during direct industrial cooperation.

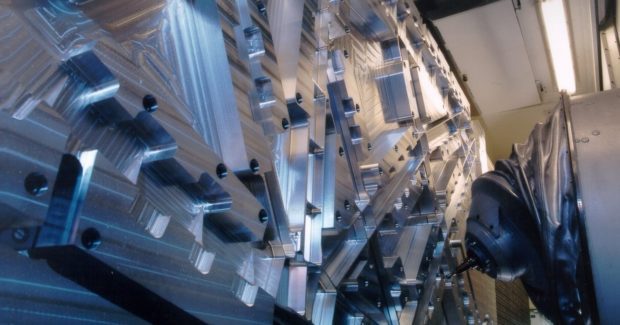

What became of the hexapod design of machine tools that was once predicted to have a great future? Parallel kinematics or hybrid solutions were found to be successful in only a few specific functions, such as handling and installation, or in highly feasible dynamic applications such as the Ecospeed machine tool from Dörries Scharmann Techology (DST; Mönchengladbach, Germany), a subsidiary of the Starrag Group (Chemnitz, Germany), that is highly productive in machining aluminum for the aerospace industry. This shows how, in the future, the machine tool industry will certainly see more special, unique machine tools that are designed for specific applications.

As machines become increasingly more complex, young people think in terms of apps . . . so how will machine tools be operated in future? The development of new, innovative man-machine concepts has a long history in our machine tool laboratory. For example, the approach of an action-based operating function that is motivated by modern smartphones has been successfully validated with multi-modal interfaces that significantly reduce the complexity of current human-machine interfaces (HMIs). Celos from DMG MORI (Bielefeld, Germany) is pursuing an entirely similar approach in this respect. In the MaxiMMI Project, whose participants include leading machine tool manufacturers and suppliers, we are currently observing the integration of new operating devices into the machine tool environment, such as smart watches, tablets or multimedia glasses. Although these approaches offer great potential, they should not be pursued just for their own sake, but should always create a practical, realistic application.

Energy efficiency has also been a recurring topic in the machine tool industry for some years. What is the situation at present? Energy efficiency is still the subject of current research funding. Whereas we were initially able to design the main units (e.g. spindles) more efficiently after taking account of physical models, more emphasis is now placed on auxiliary units and intelligent thermal management as a whole. Current activities in our machine tool laboratory involve reducing non-productive warm-up times in order to also switch off machines quickly in a flexible way during short breaks in production. From an overall viewpoint, energy efficiency must be considered broadly in the context of productivity in order to reduce the amount of energy consumption per component.