Linear AMS Expands Tooling and Manufacturing Business

Lou Young is directing their expansion of 3D metal printing into this business sector.

Posted: August 24, 2016

With their acquisition by Moog Inc. (East Aurora, NY) only months ago, Linear AMS (Livonia, MI), formerly Linear Mold & Engineering, is announcing new investment in the molding and tooling side of its business with company veteran Lou Young heading the effort.

“We are a one-stop partner for everything from mold and part design through process qualification, and it remains critical that every employee knows that every task is about adding value to the customer,” said Young. “With specialties including prototyping, mold building, and low-volume production for automotive and non-automotive companies, our 3D printing and metal AM capabilities are rewriting the manufacturing rules book. Tooling, however, remains the heart of production success. No one is bringing a stronger focus and solutions set, including 3D printing, than we are.”

The company is in the midst of adding two new account management experts for tooling and molding, in addition to new capital equipment at its Livonia injection-molding facility. This is all aimed at supporting an already strong, customer-centric culture, according to Young: “We’re at our most effective establishing collaborative problem-solving and custom solutions with our customers centered on design, engineering, prototyping, and low-volume production.”

“General interest in 3D printing and additive manufacturing is white-hot right now,” added Young. “The ability to incorporate 3D printing with traditional tooling allows us to offer established companies innovative solutions for their existing manufacturing processes (e.g. molds and castings) together with new 3D metal-printed components that can make those existing tools much better. For companies making millions of parts, a cycle time reduction of 25 percent to 30 percent can be pretty disruptive, both from the part design side and from the production side.”

What do such companies want to know about? “Mainly design techniques for cooling channels, water lines, and how we could optimize inserts for particular parts,” answers Young. “With our knowledge and experience, both on the 3D side of printing metal inserts and our mold manufacturing expertise, we can go further and simulate how those optimized designs not only work better, but maybe in 30 percent less time. We can’t mention names, but we are able to present testimonials from customers who not only used the concepts, but showed we were able to hit the improvement marks we predicted. We consider large companies that mold millions of plastic parts annually leaders because they have their molding systems down to a science. Being a part of introducing them to a disruptive technology that can drastically change their core business, is profound to see and something we intend to continue.”

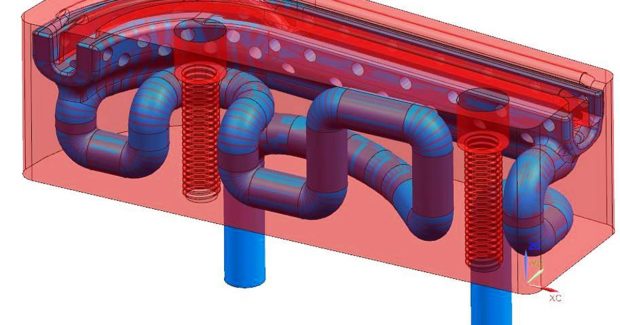

Production molds with 3D printed conformal cooling lines are a company specialty. “As opposed to drilled holes, 3D printed heating or cooling lines are designed to follow the contours of the part,” noted Young. “Placing them an optimal distance from the part surface means the mold can maintain a constant temperature and avoid warps and sinks. Testing these cooling lines with finite element analysis means we can fine-tune conformal cooling lines to accurately predict optimum mold performance and improved cycle times.”

Linear AMS has qualified cycle-time reductions from 15 percent up to as much as 45 percent. This not only means reduced energy output, but also extra capacity for a customer. Other tangible benefits include less scrap, improved final part quality, and much more flexibility when it comes to part features and the mold components necessary to make them.

www.linearams.com, www.moog.com