The Largest Qualified 3D Metal Part for European Aerospace is Here

How do you economically produce huge parts with intricate geometry that has a tendency to warp but must withstand critical applications in a demanding environment? Here’s the answer.

Posted: August 24, 2016

"Given the very low quantity of individual components for satellites and the small number of satellites in general, 3D printing is an ideal option for manufacturing. By comparison, cast parts (i.e. mold-based processes) tend to be more suitable for components that need to be manufactured in larger batches."

"The X line 1000R machine is the only machine with a build envelope that is large enough for our 3D metal printing. There are currently no other alternatives, unless you use smaller build envelopes and then join the parts together – which carries the risk of weak points in the structure. On this machine we are also able to create not just aluminum parts that are customary in satellites, but also process reactive materials, such as titanium or titanium alloys, or also nickel-base alloys – all groups of materials that are vital in other areas of aircraft construction."

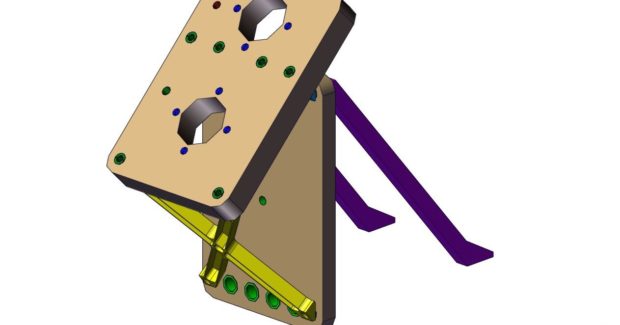

Thales Alenia Space (Cannes, France), in collaboration with 3D printing service company Poly-Shape SAS (Salon de Provence, France), has additively manufactured parts for two new South Korean communications satellites, Koreasat-5A and Koreasat-7, that will launch into orbit in 2017 to provide coverage for South Korea, the Philippines, Indonesia, India, Japan, Indochina and the Middle East. The huge antenna supports on these two satellites each measure 447 x 204.5 x 391 cu mm and are the largest volume parts ever placed in orbit that were 3D printed by powder-bed-based laser melting of metals in Europe.

Aluminum is the most commonly used material for satellites due to its weight and thermal conductivity, high strength, rigidity and resistance to corrosion. Poly-Shape used an X line 1000R metal printing machine from Concept Laser (Lichtenfels, Germany) with a build envelope of 630 x 400 x 500 cu mm for 3D printing with aluminum and a closed system for reliable process and powder management in accordance with the ATEX directives. Its unique rotating mechanism allows two build modules to be used reciprocally to guarantee constant production with no downtime and simple and secure handling when arming and disarming the machine. The patented laser melting technology uses stochastic navigation to significantly reduce the stresses involved in processing the slice segments (or “islands”) of these very large parts and prevent warping to the maximum extent possible with balanced temperature regulation of the build envelope. Using this system, it took only a few days to print this large, bionic and intricate geometry.

In the following interview, Florence Montredon, the additive manufacturing technology development manager at Thales Alenia Space, and Stéphane Abed, the chief executive officer of Poly-Shape, discuss the manufacturing challenges associated with this project.

Which techniques and processes do you use to manufacture your products?

Montredon: Given the very low quantity of individual components for satellites and the small number of satellites in general, 3D printing is an ideal option for manufacturing. By comparison, cast parts (i.e. mold-based processes) tend to be more suitable for components that need to be manufactured in larger batches. By 3D printing the antenna supports of the Koreasat-5A and Koreasat-7 telecom satellites, we wanted to demonstrate how laser melting technology opens up numerous possibilities for our applications. The essential benefits are the short timeline from design and development through to the finished part, along with the high level of efficiency.

Abed: The X line 1000R machine is the only machine with a build envelope that is large enough for our 3D metal printing. There are currently no other alternatives, unless you use smaller build envelopes and then join the parts together – which carries the risk of weak points in the structure. One theoretical alternative would have been to print the parts in two halves and join them together, but we would have lost the benefit of reducing the amount of assembly work that is involved here. The joining process may also have revealed possible defects that can be ruled out with the one-shot option of laser melting. And by making only one part we can achieve our objective faster. Furthermore, on this machine we are also able to create not just aluminum parts that are customary in satellites, but also process reactive materials, such as titanium or titanium alloys, or also nickel-base alloys – all groups of materials that are vital in other areas of aircraft construction.

What were the particular challenges of building the biggest 3D metal part?

Montredon: The first challenge was that we needed two identical twin parts: one for Koreasat-5A and the other for Koreasat-7. But the principal challenge was the size. In comparison to our previous references and experiences, the dimensions of these parts were huge.

Abed: Examples of the issues involved were feasibility, the tendency to warp, geometry and the weight. Using CAE/CAD tools, the Thales Alenia Space designers managed to optimize the geometry to suit the process, save weight and meet the load requirements. They did a very good job. The final design was then further optimized and fine-tuned in numerous redesign stages, with close collaboration and interaction between Thales Alenia Space and Poly-Shape when it came to fabrication. What we have here is a bionically optimized design.

Montredon: Both antenna supports then underwent specific elementary ground tests. They will also be submitted to usual testing at satellite level, which includes a vibration test and high temperatures in a vacuum to simulate a required lifespan of 15 years in orbit.

What new experiences were you able to gain in this project?

Abed: Aerospace provides good training and practice to be at the forefront with additive strategies. 3D metal printing requires a design that suits the process so that the advantages of a digital approach can be fully exploited. The advantages in the freedom of geometry are huge and incomparable to anything offered by conventional manufacturing technologies: digital parts look different, do more, and tend to be lighter. Certain small and medium-sized batches are often the better alternative from an economic perspective, but the limits shift upward every year so this opens up more new horizons for AM.

Montredon: To deliver the high quality parts demanded by applications in space travel, there must be a strong partnership between the end user and the manufacturer – you must be able to rely on your partner. A close working relationship and mutual interaction, with teamwork and communication between our companies, was essential to meet the ambitious timetables.

Thales Alenia Space, 5 Allée des Gabians, 06150 Cannes, France, +33 4 9292 7000, www.thalesgroup.com.

Poly-Shape Espace Green Parc, Route de Villepecle, 91280 Salon de Provence, France, +33 1 6485 1310, www.poly-shape.com.

Concept Laser Inc., 1000 Texan Trail, Suite 150, Grapevine, TX 76051, 817-328-6500, [email protected], www.conceptlaserinc.com.