Flexible Machining Center Configures to Wide Range of Applications

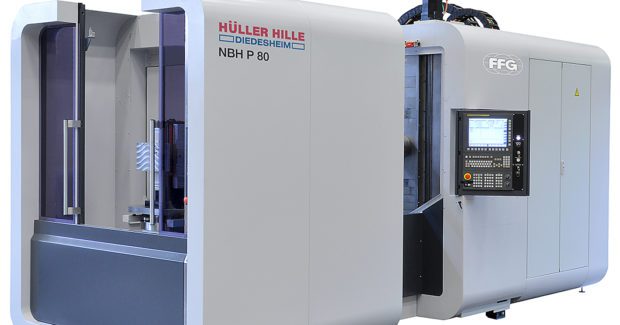

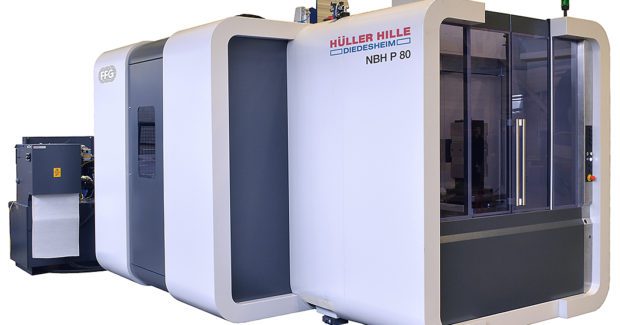

The compact Hüller Hille NBH P 80 from FFG has a choice of spindles, highly precise and dynamic rotary tables, and CNC controls that allow for flexible configuration. Its chain-type magazine has 60 locations that can be manually loaded during machine operation.

Posted: August 9, 2016

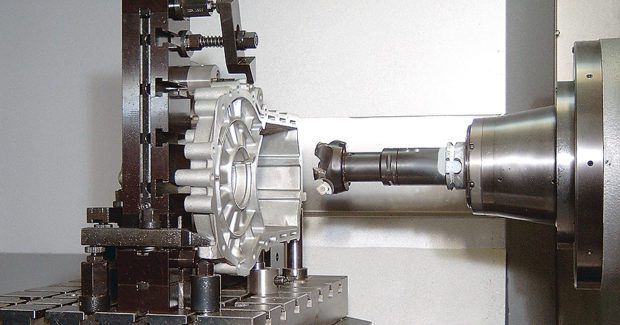

In Booth S-8129, Hüller Hille (Mosbach, Germany) premieres their new NBH P 80 flexible standard machining center, the first model of a series jointly developed within the Fair Friend Group (FFG MAG; Sterling Heights, MI) that combines Hüller Hille know-how, rigid design, state-of-the-art components and practical configuration options so that shops can profit from a high quality machine with an extended application range. Its wide work area (X: 800 mm/ Y: 800 mm/ Z: 900 mm) with extended Z-axis allows for use of long tools, even with large fixture interferences. This compact machine has a footprint of only16.5 sq m and advanced dynamics, with a rapid traverse rate of 60 m/min and acceleration of 7 m/sq sec. A rigid, double-nut ball screw drive (ø50 mm) provides for reliable machining performance. A choice of spindles, highly precise and dynamic rotary tables, and CNC controls allow for flexible configuration. The chain-type magazine has 60 locations that can be manually loaded during machine uptime. The machine tool has a pallet changer with an ergonomic 90 deg indexable setup station and a service-friendly drive unit on top of the machine.

Also on display will be the Jobs eVer7 medium-size overhead gantry milling center that is characterized by an overhead gantry structure sliding on fixed columns or on a concrete base. Jobs SpA (Piacenza, Italy), a member of FFG Europe & Americas with their Rambaudi, Sachman and Sigma brands, is a worldwide leader in the production of high performance milling machines and machining centers, particularly continuous 5-axis high speed and high torque machining technologies. The simplified eVer 7 milling center reduces the number of components compared to an equivalent machine by 35 percent without any drop in modern high speed milling performance.

The eVer 7 includes high dynamics and chip removal capacity ensured by the crossbeam structure with an MT-frame multi-triangle section; high acceleration and speeds up to 1,575 ipm through innovative mechanics and kinematics; reduced hourly operating costs; customized configurations with fixed or interchangeable heads; a wide range of accessories and possible integrated turning options; flexibility in use, ergonomics, easy loading/unloading operations; excellent enclosure for efficient chip containment and other machining residue; reduced operational costs per hour and simplified maintenance. The machine being displayed is equipped with the BUSS system for the change of automatic milling heads. It features a 3-axis power head T3A (5,000 rpm; up to 59 hp) that is particularly suitable for high-removal rate operations and a twist head T3K with a 15,000 rpm electrospindle for semi-finishing and finishing machining. The compact machine enables perfect guarding for efficient containment of shavings and other scraps.

As a member of FFG, Leadwell CNC (Taichung, Taiwan) will showcase their TW-8, T-6SMY and TM-1500 turning centers and their V-30iT machining center. The TW-8 dual spindles and turret turning center for sanitary fittings and automotive parts is equipped with 2-axis robot arms and extra-sized racks to increase both traveling speed and rigidity. T-6SMY and TM-1500 multi-tasking turning centers can process complex surfaces and geometrical features that require the various turning or milling operations in one machine. The T-6SMY offers a wide range of flexibility to handle many different workpiece requirements for small and middle-size shops. On the other hand, the TM-1500 is equipped with a B-axis that allows easier bevel angle drilling and cutting. Adopting a special electro spindle that reaches 12,000 rpm and torque 103 Nm ensures excellent performance in both the first mill and the end mill. The Y-axis is designed as a perpendicular type to match the moving column machine structure, which means the Y-axis can exercise fully without block and dead space for travel (Y-axis travel ± 200 mm).

https://youtu.be/njfmlwxJPoo

Leadwell will also present their V-30iT table-table type 5-axis machining center that reduces the time involved in constantly loading/uploading parts and fixtures, shortens processing time and improves machining accuracy.

Also on display will be high performance SPECHT® 800 and 800+ modular CNC horizontal machining centers that use MAG motorized or gear box spindles, rotary B-axis and A-axis components, and high speed tool changing systems that are ideal for rough or finish machining of large truck engine components, agricultural and off-road vehicle components, aerospace components or other general industry components. The SPECHT modular platform offers shops an industry-leading array of options, including Siemens 840D or Fanuc 31iA CNC, manual or automatic loading, box-in-box column and moving work table construction for outstanding accuracy and repeatability, high performance dual ball screw drives in each linear axis, rotary B-axis and A-axis configurations, manual or automatic work fixture clamping and unclamping, and their choice of wet, dry or environmentally friendly Minimum Quantity Lubrication (MQL) machining. The MAG team of engineering and applications experts will be available to discuss any shop’s future machining requirements and explain how they can provide not only a world-class CNC machine tool, but also a complete turnkey package of cutting tools, work holding fixtures, post-process gauges, automated machine loading / unloading and parts handling systems, and related assembly processes.

Also being showcased will be five of the latest high performance models from the FEELER Smart Manufacturing line of automated and intelligent machine tools that demonstrate cutting edge technologies of IoT, big data, cyber physical system and remote real-time monitoring for mass customization and enhanced efficiency. The FEELER U-800 5-axis gantry type machining center is developed for advanced 5-axis applications. Its gantry type, U-shaped base and column one-piece structure, provides excellent rigidity and accuracy for larger workpieces. The VB-1100, HV-1100, HV-8000 are vertical machining centers. The VB-1100 is massive, rugged, and designed for accurate production work for years. The HV-1100 and HV-8000 feature outstanding machine structure, accuracy and machining efficiency, surpassing other models of the same class. The SV-350 is a vertical machining center of column traveling type, and it is a high efficiency-high stability-high productivity machine tool.

FFG MAG, 6015 Center Drive, Sterling Heights, MI 48312, 586-446-7000, Fax: 586-532-3102, www.mag-ias.com.