Fast and Easy Benchtop Measurement of Drills and End Mills

The QVI SprintMVP benchtop system from RAM speeds up the inspection process by greatly reducing operator influence on measurements when inspecting drills.

Posted: August 2, 2016

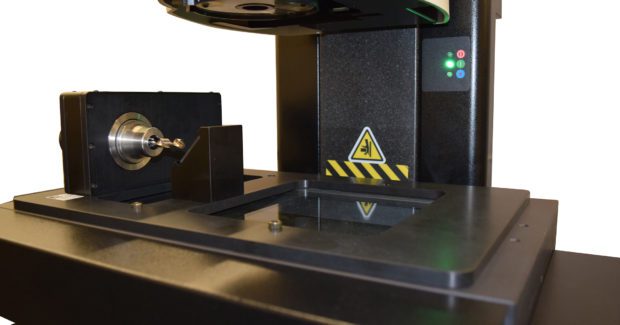

In Booths E-5602 and N-6414, RAM Optical Instrumentation (Rochester, NY) will exhibit a QVI® SprintMVP™ benchtop system that shows a fast and easy way to measure drills with the use of a custom fixture. This fixture is specifically designed for measuring drills, speeding up the inspection process while greatly reducing operator influence on the measurements. For this application, the operator loads the drill into the chuck and then places it in the pre-setter to position the drill for automatic measurement. The operator then removes the pre-loaded chuck and drill from the pre-setter and mounts it in the motorized rotary fixture on the SprintMVP stage.

From here, the operator simply runs the program utilizing QVI’s powerful Measure-X® metrology software. The automatic measurement routine aligns the drill. All geometries, including diameters and drill angles, are measured without operator intervention with 15 measurements completed in 33 seconds. The QVI SprintMVP automatic measurement system with its custom fixture allows fast, accurate measurement of drills and end mills. This system has proven effective in a large scale manufacturing environment and is also well suited for re-sharpening operations.

RAM Optical Instrumentation, 850 Hudson Avenue, Rochester, NY 14621, 585-758-1300, [email protected], www.qvii.com/ram.