Advanced Measurement Technologies

These powerful, high precision CNC vision systems and optical comparators from Starrett increase inspection productivity, speed and accuracy, even on difficult to measure complex parts.

Posted: August 18, 2016

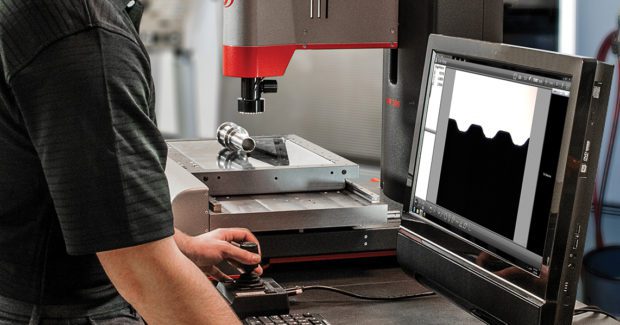

In Booth E-5532, The L.S. Starrett Company (Athol, MA) will display their AVR300 CNC vision system that offers 12 in x 8 in x 8 in travel, Z-axis measuring, a powerful MetLogix software control system, 6.5:1 (optional 12:1) zoom optics and several LED illumination options. These systems are general-purpose CNC video-based measurement systems, ideal for quality assurance, inspection labs, manufacturing, assembly and research facilities. A precision mechanical bearing X-Y-Z stage and column translates data accurately and with repeatability to the MetLogix software. This compact bench top system is precise and powerful.

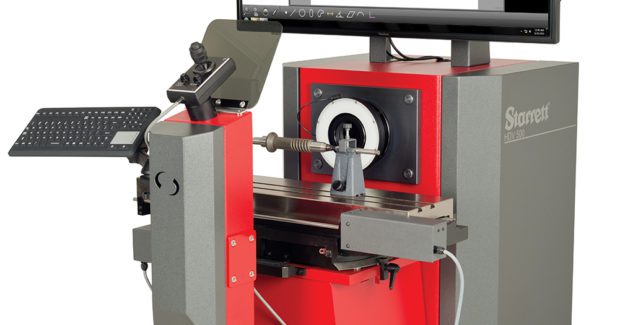

Also on display will be their innovative HDV300 Horizontal Digital Video comparator that combines the best features of a horizontal optical comparator and a vision metrology system. Utilizing a rigid steel design, with 12 in x 6 in of stage travel, the HDV is configured like a traditional horizontal comparator. The system has a uniquely mounted 5 MP digital video camera, coupled with a choice of quick change telecentric lenses or 6.5:1 zoom for micron-level resolution. The HDV system includes a powerful 64-bit PC and Touchscreen monitor, which runs MetLogix M3 Metrology software. With this software, DXF CAD files can be imported and 2D Go-No-Go gauges created, similar to using a Mylar overlay chart on a comparator screen. Video edge detection (VED), allows real-time interaction of the imported file with the video image of the part being inspected. Productivity, speed and accuracy are all enhanced.

Their HDV500 Digital Video Comparator offers the best features of a large horizontal optical comparator and a vision metrology system. Configured like a traditional horizontal comparator, the HDV500 has a long travel X-Y stage and heavy-duty steel construction. The work stage is the same as the popular HF600 and HF750 comparators, with a 330 lb (150 kg) load capacity. Much like the HDV300 and 400, the heart of the system centers on a uniquely designed interchangeable lens mounting system coupled to a hi-resolution color digital video camera (patent pending). The system is available with a choice of three telecentric lenses. The HDV systems house a powerful 64-bit PC, which runs MetLogix M3 Metrology software. With this software, DXF CAD files can be imported and 2D Go-No-Go “profile gages” can be developed directly from the CAD files. Video-Edge-Detection (VED), allows real-time interaction of the imported file with the video image of the part being inspected.

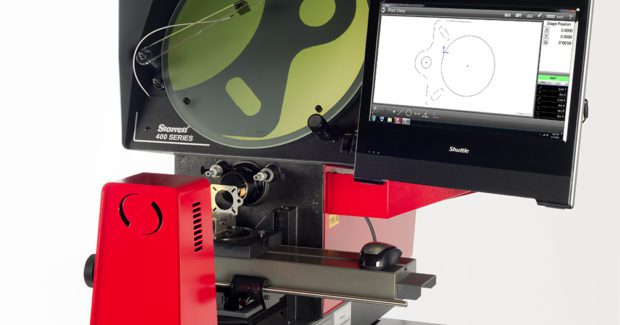

Their HE400 and HE400-M2E horizontal benchtop optical comparators offer a 16 in screen, 10 in fast traverse X-axis travel, 4 in Y-axis travel, quick change bayonet fitting lenses, Q-axis digital protractor with angular measurements to 1 ft resolution and your choice of powerful Quadra-Chek or MetLogix software control systems. A time tested, cost effective, solution for non-contact measurement. They are simple to use, yet have great capacity and performance to satisfy an exceptionally wide range of dimensional inspection applications and complex measuring requirements. At the heart of these systems are precision optics, superb lighting and a highly accurate workstage which combine to ensure bright, sharp images and exceptional accuracy. Horizontal models work well with parts that need to be fixtured, held in a vice, or on centers.

The L. S. Starrett Co., 121 Crescent Street, Athol, MA 01331, 978-249-3551, Fax: 978-249-8495, www.starrett.com.