Automated Inspection of Translucent, Punched, Turned, Formed and Laser Cut Parts

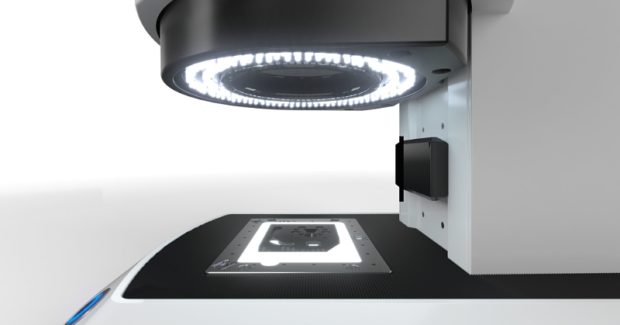

The O-Select optical measuring system from Zeiss is ideal for checking the dimensional accuracy of distances, radii or angles in punched, turned and formed parts, injection molded parts, and laser cut parts.

Posted: July 5, 2016

Factors such as depth of focus and illumination play a key role in optical measurements. Operators can cause systematic measurement errors without noticing them simply by selecting the wrong settings. The consequences of an inaccurate configuration can result in deviations of several micrometers, in depth of focus for example.

The O-Select optical measuring system from Carl Zeiss Industrial Metrology, LLC (Maple Grove, MN), continues to close the gaps in the quality assurance process with continued developments that meet even more customer requirements. It automatically selects the right distance of the camera to the object, focuses the workpiece edges and maximizes contrast. This measuring machine also calculates the illumination intensity that can vary from workpiece to workpiece.

Users no longer have to waste time searching directories for the right program. The system compares existing programs with the current workpiece and then reliably opens the right program. The system automatically detects the location of the part; manual alignment is no longer required. The system’s ISO 10360 compliancy leads the way for traceable and reproducible measurement values.

The system has a high level of automation and ease of use that is now proven to excel in the inspection of translucent parts, in addition to common punched, turned or bending parts, or injection-molded and laser-cut workpieces. It is automated during the generation of measuring programs and the measurement itself. Measurements are initiated at the push of a button: the operator places the workpiece in the measuring field and launches the program. Within seconds, the camera captures the contours, analyzes all characteristics and documents them in PiWeb quality data management software.

This measuring system is the solution for a wide range of industries, from automotive to electronics to plastics. It is particularly suitable for checking the dimensional accuracy of distances, radii or angles in punched, turned and formed parts, injection molded parts, and laser cut parts.

https://youtu.be/wiTTfwaPSS0

O-Select sets itself apart from other systems, not only through its ability to independently recognize features, but also through its intelligent suggestions for characteristics such as distances and radii. With just a few clicks, users select the required features, which are then integrated into a measuring program. The programs are created in a new self-explanatory process called Click & Pick. Furthermore, an intuitive user interface helps operators navigate the software by showing them clearly which point they have reached and then guides them through the entire run: from creating a new project to the measurement plan and specifying the measuring run, users are guided throughout the entire process up to the well-structured and informative report.

For more product information please click here.

Carl Zeiss Industrial Metrology, LLC, 6250 Sycamore Lane North, Maple Grove, MN 55369, 763-744-2400, Fax: 763-533-0219, [email protected], www.zeiss.com.