Additive Manufacturing: Making Sense of Laser Metal Deposition and 3D Printing

Because metal additive manufacturing processes are complex and require extensive material and process knowledge, it can be difficult for a metal fabricator to see how or when 3D printing might fit. To help make sense of it all, let’s consider the basics of additive manufacturing and 3D printing and how it all relates to metal fabrication.

Posted: July 27, 2016

3D printing has received a lot of attention recently, due in part to increased funding, research and development, and media attention. While 3D printing of plastics has already reached the consumer level, additive manufacturing processes using metals are a bit behind. These processes are more complex and require extensive material and process knowledge. For a metal fabricator, it can be difficult to see how or when 3D printing might fit. To help make sense of it all, let’s consider the basics of additive manufacturing and 3D printing and how it all relates to metal fabrication.

WHAT IS ADDITIVE MANUFACTURING?

While other manufacturing processes alter forms through material removal (i.e. machining), heat (i.e. forging) or mechanical force (i.e. bending), in generative or additive manufacturing, structures are built up layer by layer. Laser additive manufacturing, electron beam melting and laser metal deposition are all types of additive manufacturing processes. Although there are several metal-based additive manufacturing methods, the most common and applicable to metal fabricators are the two powder-based laser additive processes: Laser Metal Deposition (LMD), also known as direct metal deposition, and Laser Metal Fusion (LMF), or 3D printing. Both create a three-dimensional object from a digital model, yet achieve this through two very different processes.

LASER METAL DEPOSITION

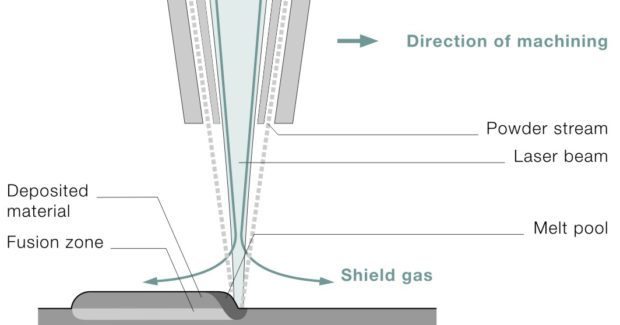

In LMD, a laser beam generates a melt pool on the surface of the component (substrate) before a stream of metal powder is blown into that melt pool and fused to the substrate. These layers are highly precise, both in overlap and size. Since the added material only minimally dilutes the substrate, in many applications a single layer is all that is needed for undiluted material at the surface. The metallurgical bond created is significantly stronger than other coating or cladding methods and it is typically applied to protect the part against corrosion or wear, such as along the edge of cutting blades for high wear resistance. Turbine blade and shaft repairs, as well as commercial diesel engine parts (pistons, heads) are also ideal applications. Since structures can be generated from scratch or be applied to an existing structure, LMD can also be used to strategically reinforce parts. The process is highly versatile which can add significant value to manufacturing and MRO-based companies.

LASER METAL FUSION (3D PRINTING)

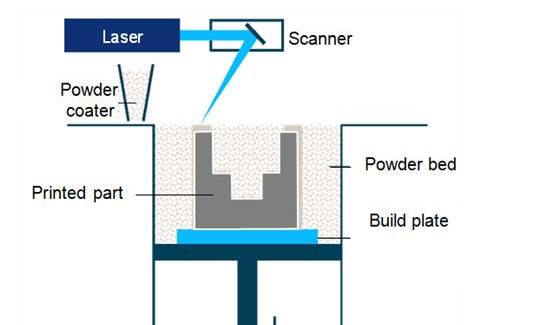

LMF is most commonly referred to as metal 3D printing. While the potential of metal 3D printing is exciting to fabricators, there is much involved in printing a 3D part. To begin, special software is used to “slice” a 3D model into very thin layers, usually 20 microns to 100 microns thick. Each slice must then be optimized for fusion quality, part density and heat management throughout the build. Using a powder-bed based laser fusion process, the part is ultimately built up layer by layer. A layer of metal powder is applied to a substrate plate and then a laser beam, directed through a scanner optic, fuses the cross section of the geometry to the plate. After the exposure the plate is lowered and the next layer of powder is applied. The process repeats until the part is finished. This can take several hours or even weeks depending on part size, layer thickness, materials used, laser power, scanning speed, spot size and other factors.

Once a part is removed from the machine, some post processing steps might be required. These include post heat treatment (if higher densities are needed, this includes hipping), removal of support structures and the build plate, machining of any interface surfaces, and final surface treatments, such as bead blasting.

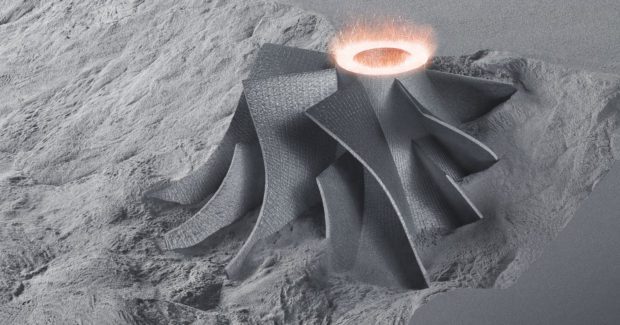

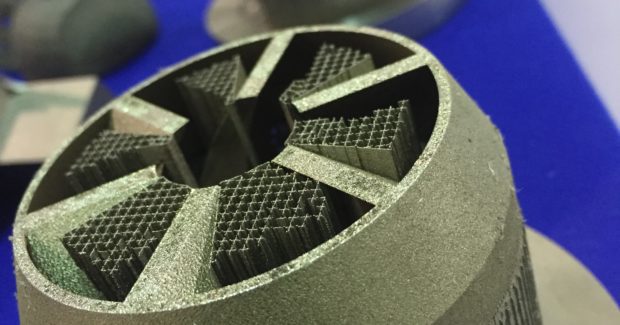

The LMF process provides for very fine or highly complex 3D structures to be built, including internal structures and surface features. An assembly of several machined parts can be redesigned and printed as a single part with the same or enhanced functionality. As a result, a new mindset and approach to engineering is required to fully exploit the advantages of this technology. There are also additional factors to keep in mind: the part’s final structure will be influenced by a variety of issues, such as the powder itself (grain size, level of spheroidization, oxygen content), laser parameters (power, spot size, scanning speed), as well as heat build-up within the build. Process and material knowledge are key for a successful print.

Metal 3D printing has already made its way into several industries, including the dental, medical and prototype markets. Hip joint implants, dental crowns and bridges made of titanium, stainless steels and cobalt chrome are all examples. A common theme here is that although the parts are produced in high quantity, each part is unique. The aerospace industry has also moved past prototype production of 3D printed parts. Here, the ability to generate hollow and light ‘bionic’ structures has enabled structural designs that are impossible with conventional manufacturing methods.

BUILDING UP ADDITIVE MANUFACTURING

Additive manufacturing grants users the ability to repair or produce parts with unique advantages compared to those which are conventionally manufactured. It can even eliminate assemblies altogether. As knowledge and understanding of laser additive manufacturing grows, these processes will become more widespread as fabricators increasingly use it to replace or complement current methods. Take a closer look and see what your shop is able to build with the help of additive manufacturing.