Three Common Questions Concerning Laser Welding in Sheet Metal Fabrication

Many sheet metal fabrication shops still hesitate to invest in laser welding. They are missing out on the numerous competitive advantages and opportunities that it offers over conventional welding processes. Here are some insights that they need to know.

Posted: June 10, 2016

Laser welding has been widely accepted by the automotive industry for decades, but in sheet metal fabrication many shops are still hesitant to take the leap. The latest advancements have made laser welding a more viable solution, reducing the cost of entry and providing sheet metal fabricators greater access to the numerous advantages laser welding offers compared to conventional welding processes. Here we address the common questions sheet metal fabricators ask when looking to add laser welding to their shop.

WHAT SHOULD I KNOW ABOUT LASER WELDING BEFORE I LOOK TO INVEST?

In sheet metal fabrication, a solid state laser emitting light at a wavelength of approximately 1 µm can be used to join materials. The focused laser beam melts the material locally and with minimal heat input resulting in minimal distortion of the material. Three main parameters determine the laser welding process: laser power, weld speed and focal positioning.

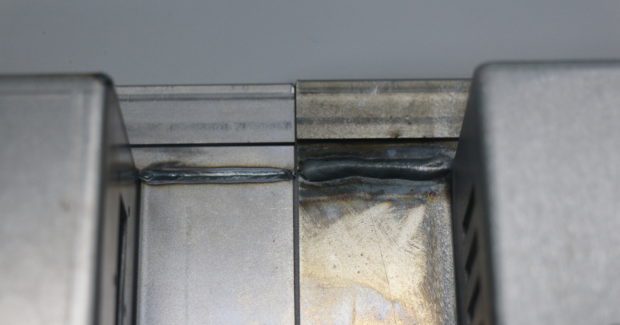

In heat conduction welding, cosmetic weld seams with smooth surfaces result and often eliminate or dramatically reduce secondary processes like grinding or straightening. Typical applications include covers (Figure 1) and boxes, or fixtures such as counters and sinks for the medical or food service industries. With deep penetration welding, weld speeds of 40 ipm to 200 ipm, in combination with high weld strength, can be realized. This welding technique is used when full penetration, high part stiffness or sealed and tight weld seams are required. Applications include pressure tanks (Figure 2), brackets or flanges (Figure 3). Both techniques offer consistent weld seam quality, decreased heat input and negligible distortion of welded components. Due to the small spot size of the laser, the heat input is typically 200 times lower than with arc welding processes like MIG, MAG or TIG welding.

To fully reap the benefits of laser welding, a fabricator must commit to high-quality sheet metal processing prior to welding. As a rule of thumb, material gaps in the weld zone should be limited to approximately .008 in, although this can vary based on the application. Luckily, these tolerances are easily met by modern 2D laser cutting machines and press brakes. Although parts can typically be converted from arc welding to laser welding with just minor adjustments to the design, laser welding does provide design engineers with new opportunities, such as overlap welds, corner welds and flange welds. Even complex joint geometries like curved shapes (Figure 1) or materials with different sheet thicknesses can be laser welded.

WHAT MATERIALS AND SHEET THICKNESSES CAN BE JOINED WITH A LASER WELDING CELL?

While mild steel, carbon steel, stainless steel or aluminum are most commonly seen in laser welding, fabricators are not restricted to these materials. It is also possible to join dissimilar material or materials like coated steel, copper or titanium. With laser welding, the maximum sheet thickness depends on the welding technique as well as the material. Typical sheet thicknesses for heat conduction welding with a 3 kW laser are approximately 3 mm (.120 in) for steel and 2.5 mm (.100 in) for aluminum due to the material’s high reflectivity and thermal conductivity. The weldable sheet thicknesses increase when deep penetration welding or a higher laser power is used.

HOW DO THE ADVANTAGES OF LASER WELDING INFLUENCE PART COSTS AND ROI OF A LASER WELDING CELL?

For most laser welded sheet metal parts, the weld quality and the speed of processing are superior to conventional welding processes, and this ultimately results in increased profit margins. If you consider the complete sheet metal fabrication process (i.e. cutting, bending, punching and welding), welding and refinishing affect approximately 70 percent of the cost per part. This is mainly due to the length of time required and the high consumption costs associated with these processes. These main cost drivers are reduced by laser welding’s consistent quality and cosmetic seams.

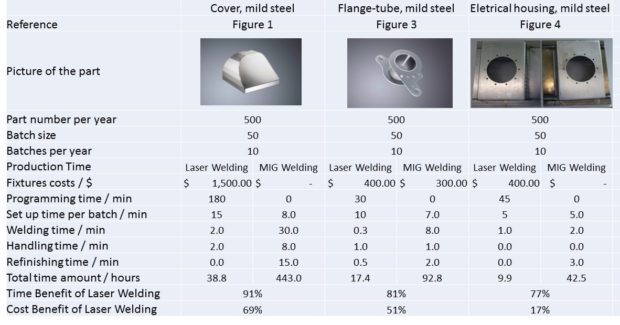

This is illustrated by the sample parts mentioned previously (Table 1). Each sample considers welding and refinishing time, including programming and setup, as well as consequent costs such as fixturing. For each sample, it is assumed that 500 parts are manufactured per year. Production time of the mild steel cover shown in Figure 1 was reduced by 91 percent by laser welding instead of TIG welding. In addition, part costs were reduced by 69 percent, considering the hourly rate of the laser welding cell is higher than that of TIG welding. For the mild steel flange depicted in Figure 3, production time was reduced by 81 percent while total cost diminished by 51 percent.

Welding the electrical housing made of .060 in thick mild steel, shown in Figure 4, cut production time to just 9.9 hours per year with laser welding for a time reduction of 77 percent and a cost reduction of 17 percent, compared to MIG welding. Furthermore, quality increased by way of a smoother surface for its laser welded seams. While these calculations are based on average values and the results will vary based on the application, the time and cost savings associated with laser welding tend to be impressive.

Since sheet metal fabricators benefit from the laser welding process in various ways, the ROI varies based on the production requirements of the shop. However, a laser welding cell can achieve a very high return on investment based on typical calculations. For example, pay-off time is roughly three years when a fabricator processes parts similar to those discussed above. This is true even when machine utilization is less than 50 percent and only active one shift per day. In addition, it is also possible to minimize investment costs by creating a laser network (Figure 5). Using an existing laser resonator from a 2D laser cutting machine to support laser welding operations can reduce investment costs of the laser welding cell by up to 40 percent.

While most sheet metal fabricators will benefit from the numerous advantages of laser welding, many are still hesitant to make the investment. To overcome this concern, consider the needs of your sheet metal shop and how laser welding might impact production. Consult with industry experts who can help evaluate your parts, answer questions and show you how laser welding opens up new opportunities.

Subscribe to learn the latest in manufacturing.