Smooth Machining of Difficult to Access Areas

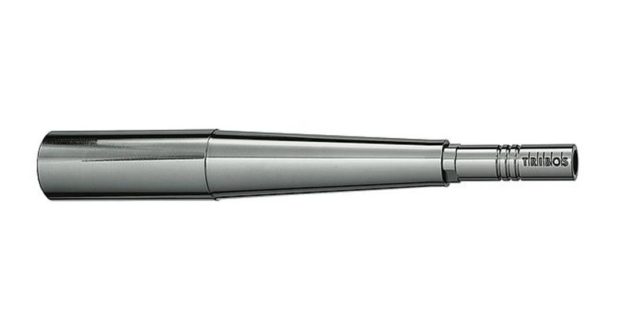

The slim design of TRIBOS-SVL toolholder extensions by SCHUNK allows precise and smooth machining of areas on parts that are difficult to access.

Posted: June 7, 2016

The slim design of TRIBOS-SVL toolholder extensions by SCHUNK Inc. (Morrisville, NC) allows precise and smooth machining of workpiece areas that are difficult to access. In spite of the slim design, these extensions are robust and permit a run-out accuracy of less than 0.003 mm. They can be combined with a variety of toolholders, such as TENDO hydraulic expansion toolholders, CELSIO heat shrink toolholders, with collet toolholders and with TRIBOS toolholders.

These extensions, in connection with TENDO hydraulic expansion toolholders or the TRIBOS-R polygonal toolholders, complement each other in an ideal manner. Both systems have a vibration damping effect on the overall system. The extensions have a wide range of clamping diameters and are available in metric from 0.3 mm to 20 mm and from 1/8 in to 3/4 in.

SCHUNK is a German family-owned company and global player in clamping technology and gripping systems that include grippers, rotary modules, linear modules, robotic components, sensors and accessories. With a total of 11,000 standard components, they offer one of the world’s largest assortment of clamping technology and gripping systems.

SCHUNK, Inc., 211 Kitty Hawk Drive, Morrisville, NC 27560, 919-572-2818, Fax: 919-572-2818, [email protected], www.schunk.com.