NextGen Spaceframe Combines Lightweight Construction and Flexibility

A functionally integrated, bionically optimized vehicle structure offers new potential for lightweight construction and greater manufacturing flexibility of automobiles.

Posted: June 1, 2016

Manufacturers are currently required to integrate an increasing number of drive concepts and energy storage systems into vehicle structures. The vehicle bodies of tomorrow – particularly in view of alternative drive systems in small series with lots of different versions – will not only need to be lighter, but above all will also require a highly flexible design. The result is an increasing number of vehicle derivatives which demand adaptable bodywork concepts that are economical to manufacture. In the foreseeable future, additive manufacturing could offer entirely new possible approaches.

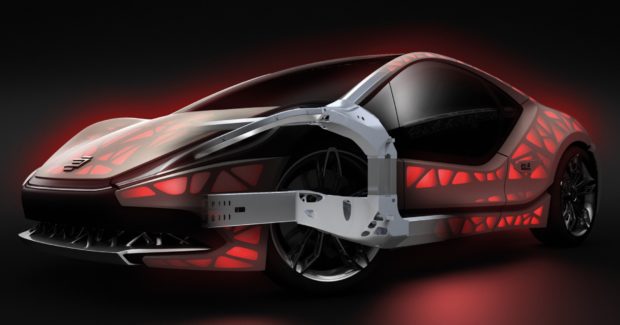

One recent example of this is the “Light Cocoon” concept car from EDAG Engineering GmbH (Wiesbaden, Germany), a compact sports car with a bionically designed and additively manufactured vehicle structure that is covered with an outer skin made from weatherproof textile material. The Light Cocoon is intended to polarize opinions among designers and breaks open existing thought patterns in vehicle design. The bodywork structure embraces bionic patterns and translates them into a lightweight bodywork structure – a concept car that highlights sustainable approaches and at the same time embodies the technological potential of additive manufacturing.

Now a joint technology project involving EDAG, Laser Zentrum Nord GmbH (Hamburg, Germany), Concept Laser GmbH (Lichtenfels, Germany) and the BLM Group (Cantù, Italy) used hybrid manufacturing to create the NextGen, a bionically optimized spaceframe that highlights a new way to flexibly manufacture an adaptable bodywork concept for an increasing range of different vehicles and manage the large number of different drives and load stages. Additively manufactured bodywork nodes and intelligently processed profiles are combined. Thanks to additive manufacturing, the nodes can be configured to be highly flexible and multifunctional so that, for example, different versions of a vehicle can be produced “on demand” without any additional tooling, equipment and start-up costs. Steel profiles are used as connecting elements. They too can easily be adapted on an individual basis to the specified load levels by providing them with different wall thicknesses and geometries.

THE NEXTGEN SPACEFRAME IN DETAIL

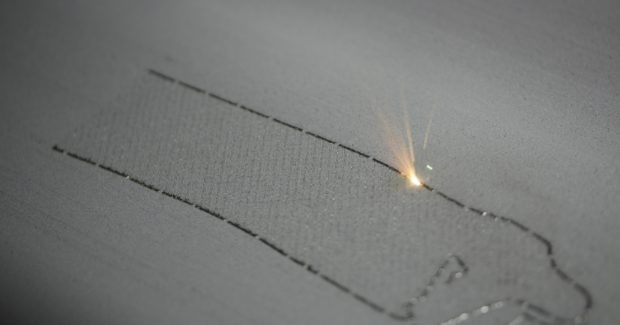

The NextGen spaceframe is a combination of additively manufactured 3D nodes and intelligently processed steel profiles. The nodes can be manufactured on site ‘just in sequence’ (JIS) along with the profiles for the particular version needed by order, which are cut to the appropriate shape and length initially using 3D bending and then by employing 2D and 3D laser cutting processes. The focus is on joining together individual components to create a hybrid structure to produce topologically optimized structures that are not yet possible currently.

The method used is laser welding, which is characterized by intricate welded seams and low thermal input. The components are welded together with a fillet weld on the lap joint. The geometric basis for this is the complete shoeing of the profiles all the way round. This is also produced on demand via additive manufacturing through 3D measuring of the profiles. This joint enables circumferential welding to produce a connection over a long length along with excellent prepositioning of the components. The profiles are automatically aligned and fixed in place by the node. A high-brightness laser with robot-guided optics is used. Also, the laser techniques used to produce these profiles and nodes can largely be automated in assembly, offering great potential to save time and reduce the manufacturing cost structure.

The additively manufactured nodes can be adapted to reflect each load stage, e.g., by incorporating additional stiffening elements to cater for high load requirements. This means each version is designed for the optimum weight and function. The hybrid design spans the required distances of the structure with the profiles while the nodes are used to connect the profiles together. Both elements were optimized using CAE/CAD and guarantee the requirements that are demanded of a bodywork structure. During the project EDAG was responsible for devising and optimizing the spaceframe concept, as well as playing a coordinating role. Laser Zentrum Nord did the laser welding, BLM undertook the 3D bending and laser cutting, and Concept Laser performed the additive manufacturing of the nodes.

The success of the NextGen spaceframe project reflects the interdisciplinary collaboration between these complementary partners and the high level of expertise of each individual technology specialist in their specific discipline.

PRODUCTION OF NEXTGEN SPACEFRAME NODES

The LaserCUSING process from Concept Laser generates components in layers directly from 3D CAD data to allow production of components with complex geometrical shapes without the use of any tools. It is possible to produce components that would be very difficult or impossible to fabricate by conventional manufacturing. With this type of design, the nodes cannot be manufactured by conventional steel casting. In order to be able to guarantee a fault-free structure, a support structure should be provided on planes with an angle of less than 45 deg in relation to the build platform. As well as providing simple support, the support itself absorbs in particular internal stresses and prevents the components from warping. Due to the complex geometry of the nodes, clean support preparation is the absolute basis of successful production. After preparing the support, the component is virtually cut into individual slices.

Once the data has been transferred to the LaserCUSING machine, the corresponding process parameters are assigned and the build process is started. The nodes were manufactured on an X line 1000R machine that has the appropriate build envelope (630 x 400 x 500 mm3) for such projects and operates with a 1 kW laser. Only the new X line 2000R (800 x 400 x 500 mm3) has a larger build envelope for powder-bed-based laser melting with metals, and it is also equipped with 2 x 1 kW lasers.

DIGITAL 3D MANUFACTURING STRATEGY WITH LASER TECHNOLOGIES

The spaceframe concept combines the flexibility and the potential for lightweight construction advantages of 3D printing with the efficiency of proven conventional profile designs. The laser plays the key role in both technologies. The topologically optimized nodes enable the maximum lightweight construction that is currently possible along with a high degree of functional integration. Both the nodes and the profiles can be adapted to new geometries and load requirements without any additional outlay. This translates into the possibility of designing every single part to cater for the level of loading and not dimensioning the components to reflect the greatest motorization or load stage, as was previously the case.

The basic idea is to have a node/profile design that can be optimally customized to reflect what the particular model requires. The result is a spaceframe structure with an optimized load path. By employing processes that do not involve much use of apparatus or tools, it will be possible in the future to manufacture all bodywork versions economically and with the greatest possible flexibility.