Minimum Unit Costs Through Productive Automatic Turning

Capable of machining both short and long components with equal excellence, the SPRINT 32|5 and expanded SPRINT 32|8 Swiss-type automatic lathes from DMG MORI minimize unit costs when machining bar material lengths up to 23.6 in.

Posted: June 5, 2016

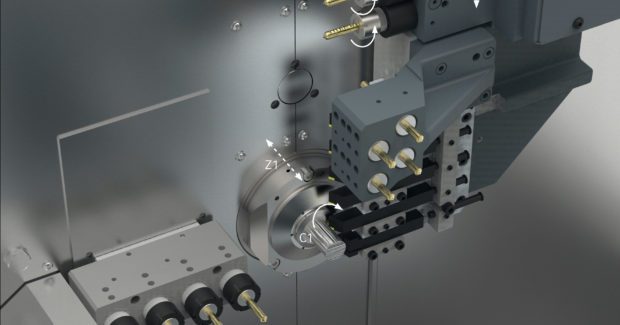

DMG MORI USA (Hoffman Estates, IL) has now expanded their series of Swiss-type automatic lathes equipped with a SWISSTYPEkit to include the SPRINT 32|5 and SPRINT 32|8 for bar material with diameters up to 1.26 in. Their capability of machining both short and long components with an equal degree of excellency make these machines ideal for shops needing further reduction in cycle times.

As versatile, top-performance automatic lathes, the SPRINT 32|5 and SPRINT 32|8 each have a footprint of only 30.1 sq ft, making them the most compact machines in their class while at the same time offering a large work area for workpieces of up to ø1.3 in x 23.6 in. Both models derive their versatility from the proven SWISSTYPEkit that enables both short and long turning on one machine – with setup times of less than 30 minutes. To achieve this, the spindle stroke is lengthened from 3.9 in to 9.4 in. An optional quick tool-change system reduces setup times by another 20 percent.

The SPRINT 32|5 comes with five linear axes and a C-axis on the main spindle and has two independent tool carriers with space for up to 22 tools. There are four pockets available for powered tools for radial machining on the main spindle. The expansion option SPRINT 32|8 is ideally suited to the machining of more complex workpieces. The machine has an additional Y-axis for the second tool carrier plus a C-axis for the counter-spindle. The SPRINT 32|8 is equipped with a total of six linear axes and two C-axes and has 28 tool pockets. This expansion option of the machine has a third independent tool carrier that is suitable for deep hole drilling on the main spindle, for example, and that also enables 4-axis machining on the main spindle. These two stations can also be equipped optionally for powered tools. The second tool carrier has eight pockets for rear-side machining, four of which are equipped for powered tools. There are pockets for a total of ten (eight in the standard version) powered tools.

The two-channel CNC control of the SPRINT 32|5 – a FANUC 32i-B with 10.4 in color display – controls five linear axes altogether and the C-axis of the main spindle. The SPRINT 32|8 has six linear axes and a C-axis on both the main and the counter-spindle. So both expansion options can be used to realize highly-complex and – in combination with the machine technology – high-precision applications.

Both of these machines also offer top quality where the spindles are concerned. Where other suppliers still cling to their belt drives, GILDEMEISTER Italiana has installed high-performance motor spindles with direct drives throughout, which can handle even materials that are difficult to machine. There is a high-pressure coolant supply with up to 120 bar available for just such demanding high-performance machining. The SPRINT 32|5 and the additional SPRINT 32|8 expansion option have been developed with the aim of minimizing unit costs for the machining of bar material,and the list of optional equipment includes an unloading unit for workpieces with lengths of up to 23.6 in.

Highlights on both the SPRINT 32|5 and SPRINT 32|8 include:

- Workpieces up to ø1.3 in × 23.6 in on a footprint of less than 30.1 sq ft

- Unloading unit for long workpieces up to 23.6 in. via the counter-spindle (optional)

- SWISSTYPEkit for short and long turning operations on a single machine, < 30 min setup time

- 20 percent shorter setup times thanks to the quick tool-change system (optional)

- High-pressure coolant supply (optional) up to 120 bar

- FANUC 32i-B with 10.4” color display

Highlights on the SPRINT 32|5 include:

- Five linear axes and one C-axis

- 22 tools on two independent tool carriers

- Four powered tool pockets for the main spindle (radial)

Highlights on the SPRINT 32|8 include:

- Six linear axes and 2 C-axes

- 28 tools on three independent tool carriers for 4-axis machining on the main spindle

- Four powered tool pockets for the main spindle (radial)

- Two stationary deep-hole drill tool pockets for the main spindle (frontal), powered as an option

- Four powered tool pockets for the counter-spindle (frontal)

DMG MORI USA, 2400 Huntington Boulevard, Hoffman Estates, IL 60192, 847-593-5400, Fax: 847-593-5433, us.dmgmori.com.