Before You Automate That Welding Operation

No shop can benefit from welding automation if the operation simply consists of moving a bottleneck from one department into another. To avoid missing out on the overall productivity and efficiency a robotic weld cell can deliver, these four challenges must be addressed before automating the welding operation.

Posted: June 10, 2016

A robotic welding system can help shops improve their efficiencies, eliminate waste, produce better products, and generate greater profitability and competitiveness. For those that are new to automation, it is important to plan carefully before purchasing a system and follow some best practices to gain the most out of the investment. Below are four key challenges to consider when automating a welding operation, along with recommended solutions.

START SIMPLY AND CAREFULLY

Welding automation is an investment in both sides of the equation for success: in technology and in employees. The trick is to find a balance between reducing waste (material and money) and increasing productivity and quality, which should be done incrementally. Ideally, the physical and human capital will grow in unison. This means training robotic weld cell operators so they can use the robot most effectively to boost productivity and quality. It is also imperative to tackle each welding automation project one step at a time. Start by automating production of simple, repeatable parts and then move to more complex ones. For example, consider a heavy equipment manufacturer that invests in a welding robot for the very first time. This shop would be better served to automate the welding of sub-assemblies for a backhoe frame first, as opposed to investing in a robotic welding system that welds the entire frame.

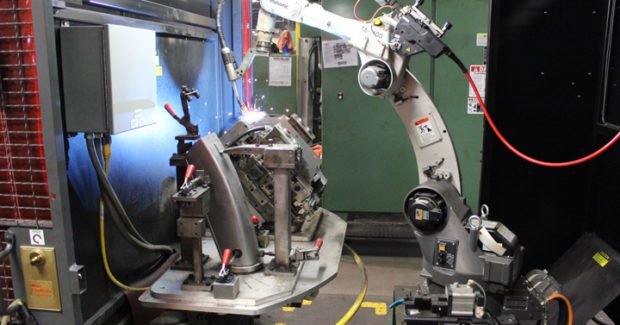

For first-time users, pre-engineered robotic weld cells are often the best option. These systems are an easy-to-use solution that includes all of the equipment needed – pre-wired and pre-assembled – for automated welding. These cells are a better alternative than buying a used system and trying to retrofit it because used systems often do not meet current safety standards, which can create a host of unforeseen and potentially costly problems.

GAIN BUY-IN AND INPUT

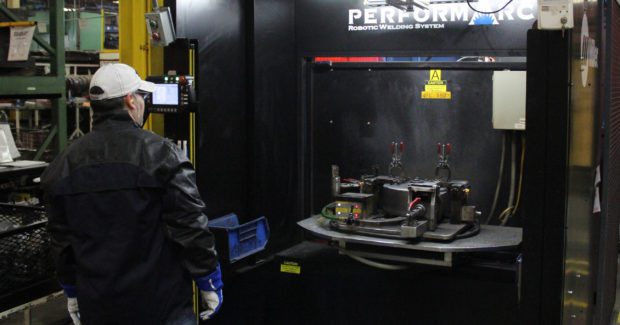

Buy-in and input from management and from welding operators are most important in making the investment in a robotic welding system successful. These two groups, respectively, are responsible for approving the purchase and making it operate as efficiently as possible. Before gaining buy-in from welding operators, help them understand the different opportunities a robotic welding system presents. Some of them fear welding automation will ultimately make their jobs obsolete, but the truth is skilled employees are becoming harder to find in the United States as more shops fight to stay competitive, particularly against manufacturers abroad.

Robotic welding systems actually provide welding operators with the chance to learn new skills and become more valuable by helping their company grow. In some cases, the technology also opens up the opportunity for promotion and long-term career advancement. Not only can welding operators become robot programmers – an excellent way to expand their skill sets and viability – but automated systems can also free up skilled operators for manual welding of more complex, higher difficulty welds.

DETERMINE PART MIX AND FIT-UP

To determine if welding automation is the right choice for your shop, ask one key question: Are the parts good for a robot? The best options are simple, repeatable parts with minimal gaps. Always have a robotic integrator or robot OEM evaluate the part to determine its suitability; doing this up front can minimize unnecessary and expensive issues. Part evaluation is often as simple as providing an electronic CAD drawing for review of the part. Some parts are not well-suited for automation because they require a high degree of operator input. For example, a part with a very tight access point that requires manipulating the gun in a small, confined space would not be a good fit for automation because there would be difficulty gaining joint access with the robotic MIG gun.

High volume, low variety applications are very well-suited for automation because they require minimal considerations when it comes to tooling changes. However, if small batches of product can utilize a quick tooling change, then it is also possible to produce a low volume part efficiently. Timing is everything in this situation: if it takes a welding operator one hour to change the tooling for ten welds that they could easily complete by hand in the same amount of time, then it’s smarter to do them by hand. It is important to note that once a program is in the robot, it’s always there. So although there is an investment of time up front to create the program, it is simple to recall for future use on both larger and smaller volume part runs.

ANALYZE WORKFLOW

A robot welding system can increase throughput significantly, but before implementing one, ask these questions: Are the rest of the operations ready for the increase in throughput? Can upstream manufacturing processes continue to deliver the necessary quantity to the robot? Can downstream processes (such as paint, packaging or assembly) handle the higher production? When looking at the flow of parts in a welding operation, it’s critical to consider the whole picture. Ensure that any rework required of the part before entering the weld cell has been eliminated from the process and that the employees supplying parts to the robot can match its cycle time.

Ask these questions ahead of implementation and plan accordingly so that everything continues to flow smoothly. No shop can benefit from welding automation if the operation simply consists of moving a bottleneck from one department into another; it is possible to miss out on the overall productivity and efficiency a robotic weld cell can deliver. Always remember, any investment in the welding operation should be made with care. Consult a trusted robot OEM, integrator or manufacturer for assistance.