Abrasive Waterjet Produces High Precision Parts from Any Material

OMAX will demonstrate how their JetMachining Centers can cut high precision 3D and taper-free parts from virtually any material and thickness without the need for tool changes.

Posted: June 12, 2016

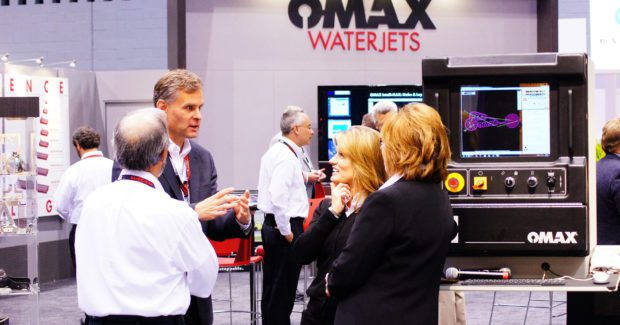

In Booth N-6228, OMAX Corporation (Kent, WA) will highlight how their abrasive waterjet technology is engineered to provide successful cutting solutions with live cutting demonstrations that showcase how quickly their JetMachining Centers can produce high precision parts from virtually any material. Visitors can watch 3D and taper-free parts being cut from various material types and thicknesses without the need for any tool changes. “We want shops who visit our booth to gain a solid understanding of how the speed, performance and versatility of abrasive waterjet technology can help them grow their businesses,” explains Stephen Bruner, the vice president of marketing for OMAX. “This easy-to-use technology enables companies to improve productivity and take on new, more complex work.”

Application specialists will be available to educate visitors about abrasive waterjet technology and explore customized solutions for specific cutting needs. Installation technicians will address questions about set-up and maintenance, and customer service personnel will explain the world-class training and support that OMAX provides in-person, online and over the phone. Of special note, lead software engineer Carl Olsen will give a presentation titled “The Role of Software in Waterjet Machines” as part of the Alternative Manufacturing continuous improvement learning track at the show. In his presentation, Olsen will discuss how waterjet software improves machine operations, intelligence and cutting speeds.

OMAX Corporation, 21409 72nd Avenue South, Kent, WA 98032, 800-838-0343, Fax: 253-872-6190, www.omax.com.