Smart Tooling for Greater Efficiency

In a major step toward the smart factory of the future, the Tool-ID system from Walter controls tooling plant-wide, saving time, boosting productivity and increasing process reliability.

Posted: May 9, 2016

It’s common for manufacturers to strive to improve their products, but precision tool specialist Walter USA, LLC (Waukesha, WI) not only strives to improve its products but the manufacturing process as well, as exemplified by its new Tool-ID system. Aimed at keeping machine downtime and processing times to a minimum, this innovative solution allows the user to transfer tool data from the pre-setting device to the machine tool, and to evaluate the parameters that are run on the machine. The data is assigned to the tool via an identifier, for example a laser-engraved data matrix code on the tool.

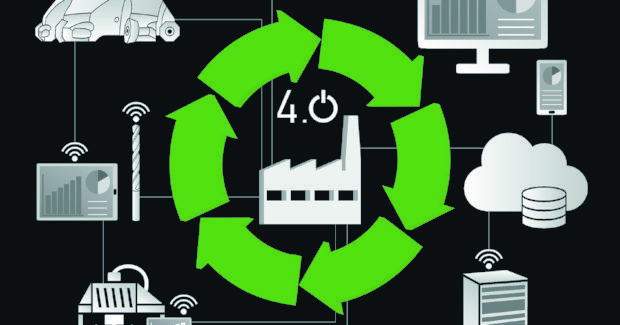

The data is called up using a scanner and automatically transferred to the machine control unit – meaning that time-consuming and error-prone manual data entry becomes superfluous. This is an essential component for communication between the tool and the machine. The tool also provides production information in a form that can be read by the machine and used to monitor and control tool life or presetting data, as well as the individual production steps. Through this comprehensive overview, it is possible to detect potential problems early on and remedy them promptly. Thanks to Tool-ID, shops can move one step closer to the vision of Industry 4.0, the smart factory of the future.

https://youtu.be/3D91HZ3yfVY

ALL DATA AT THE TOUCH OF A BUTTON

In the smart factory, production and operating sites are linked in such a way that all processes can be coordinated centrally and controlled automatically. Walter is currently developing a “System of Systems” in addition to Tool-ID which takes them even closer to the smart factory. This solution allows all the accessible data within the production environment to be viewed and processed according to the user group. “The aim of this new development is to digitize all relevant information relating to the production process and make it available for analysis and optimization,” explains Holger Langhans, the director of Walter Multiply.

This universal, fully integrated “System of Systems” digitally links all production units involved in the process via a shared server, which means the user can, for example, quickly call up and view all changes made in the machining programs. In the future, users will be able to view, combine and evaluate data at the touch of a button from a workstation, or by using apps on a smartphone or tablet. This gives them a complete view of the processes in real time. Downtimes and processing times are reduced and damage to components and equipment is minimized, all of which has a positive impact on productivity. The solution is aimed primarily at facilities that have ten or more CNC machines.

Walter, a global leader in the metalworking industry with over 90 years of experience in precision cutting tools for milling, drilling, turning, boring and specialized tools, helps shops improve their process reliability and increase their productivity. With regional headquarters in Waukesha, the company markets its competence brands Valenite, Titex, Prototyp and Multiply through a strong network of distributors and field engineers across subsidiaries in the U.S., Canada, Mexico, Brazil and Argentina.

Walter USA, LLC, N22 W23855 Ridgeview Parkway West, Waukesha, WI 53188, 800-945-5554, www.walter-tools.com/us.