Shaping Tomorrow’s Production

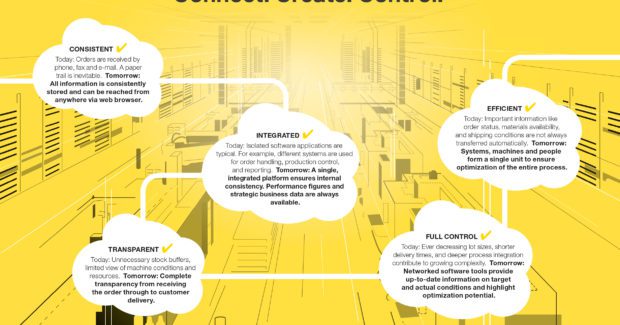

A new IT services platform supports the entire production value chain – regardless of the manufacturer – with modular solutions that allow shops to transition into Industry 4.0 at their own speed, step by step.

Posted: May 9, 2016

There are a variety of IT services providers in the market, but are there any that also understand the ins and outs of production? This is precisely where the strength of AXOOM GmbH (Karlsruhe, Germany) lies. With TRUMPF GmbH + Co. KG (Ditzingen, Germany) as their parent company, this new IT services firm is a decisive step ahead of other software firms. Their ability to build IT solutions that optimize production processes is rooted in an intimate knowledge of the complexity and non-standardized processes faced by small and medium-sized shops that comes from practical experience and a foundation of machine know-how.

STEP BY STEP TOWARD INDUSTRY 4.0

The new digital business platform operated by AXOOM uses tailor-made modules along the value chain to help smooth the path toward Industry 4.0. “With this IT service we are thinking outside the box and are advocating a new, digital and open business platform that covers the entire value chain, regardless of the manufacturer involved. Machines and systems from a variety of providers, working together intelligently . . . this is the future,” explains Mathias Kammüller, Dr. Eng., executive vice president of TRUMPF and head of their Machine Tools division.

AXOOM does not stop at the shop walls, but instead supports users continuously – from the supplier to the end customer. TRUMPF is very consciously setting up AXOOM an independent company. “It is intended to create something entirely new, beyond existing convention. We are supporting them with our entire know-how as a machine tool manufacturer. Our common goal is to achieve the highest productivity and profitability for our direct customers, as well as various other production companies,” adds Kammüller.

THE KEY: AN OPEN AND MODULAR PLATFORM

AXOOM addresses the problem of growing complexity in the manufacturing industry. For example, consider the issues caused by declining batch sizes. Modern machines turn out parts so quickly that they offer very little potential to reach greater productivity. The situation is entirely different when it comes to the processes that precede and follow the actual production of a part: from taking a customer’s order, then to materials procurement and order scheduling, and on through to invoicing; there are many opportunities to save time and expense. This is exactly where Industry 4.0 and this IT service come into play. “The key is an open business platform that is holistic in design and encompasses the entire value chain,” explains Florian Weigmann, the managing director of AXOOM. “With our product offering, we want to help shops by simplifying process steps within production, synchronizing them, and bringing overall productivity to an entirely new and higher level.”

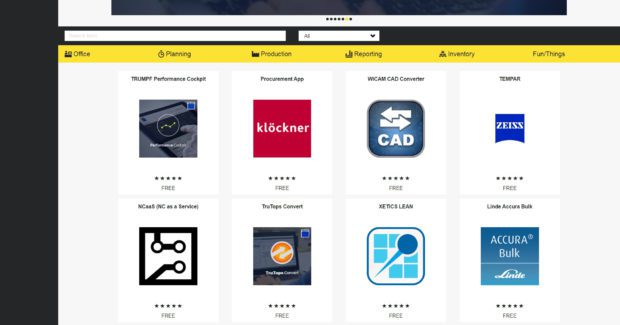

As an open platform, this IT service will be available to all customers, their suppliers and service contractors, as well as to other partners. Components made by different manufacturers within the production value chain can be networked together and are thereby able to work together intelligently. In addition, this IT service is modular in its design and can be scaled to suit so that users have the possibility to replace individual process steps one by one toward a more seamless solution. “What’s more, additional value can come as a result of our partners being able to integrate their own products into our IT service. Everything is available within an open system – unified, integrated and transparent,” notes Weigmann.

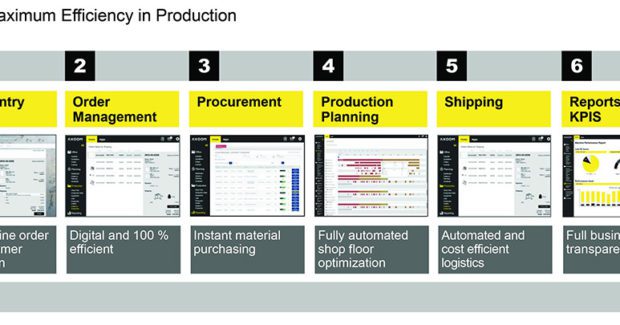

Already included as AXOOM partners are companies such as the digital daughter company of the Klöckner & Co SE – kloeckner.i GmbH, Linde AG, J. Schmalz GmbH, SICK AG, WiCAM GmbH Technische Software, XETICS GmbH and Carl Zeiss Industrielle Messtechnik GmbH. Beginning immediately, those interested in participating can pre-register at www.axoom.com for a preview of the new platform. During the preview phase, users will be able to try out the first modules at no charge. The first consistently integrated modules for the preview include: order and resource management, logistics, production planning and shop floor as well as reporting.

The order management module relegates faxes and paper to a less prominent role. Every inquiry received will be digitally documented. The data are then transferred efficiently through to the order list: materials needed, number of items, delivery address and as well as the drawing of the part. Regardless of whether the client orders directly in the online shop or sends their requirements by email. The module resource management administers all resources, continuously and efficiently. It enables prompt deliveries and purchasing with a push of a button. In order to achieve this, AXOOM automatically reports when materials needed for the order are in short supply and need to be reordered. With a single click, the dispatcher approves the purchase and requests the material from the supplier – directly and without needing to change systems. One example of this is steel provider Klöckner & Co., whose product offering is incorporated into AXOOM.

In the logistics module, finished orders are automatically readied for delivery. To guarantee cost efficiency, AXOOM compares the bids from various shipping companies and automatically enables the printing of the shipping labels. If requested, the IT service will provide order and shipping data for proofing. The foundation for the production planning module and the shop floor is a dynamic planning algorithm which responds instantly to rush orders or malfunctions and proactively recommends solutions.

Once the production manager has signed off on the incoming order, suggestions for optimal production scheduling will be automatically generated. The complex tasks of material provisioning and scheduling of machines and personnel – along with determining the sequence of processing steps – are optimized independently by AXOOM, acting as a manufacturing advisor. The operator always has the option of intervening. The result is an optimized production path. The shop floor function acts as a central navigation element for the platform, offering monitoring and a complete overview of production. The reporting section provides a transparent overview of all business processes. Key figures on machines and the business itself are kept up to date and available at all times, and any possible warning notifications are quickly visible.

UNMANNED PUNCHING OPERATIONS

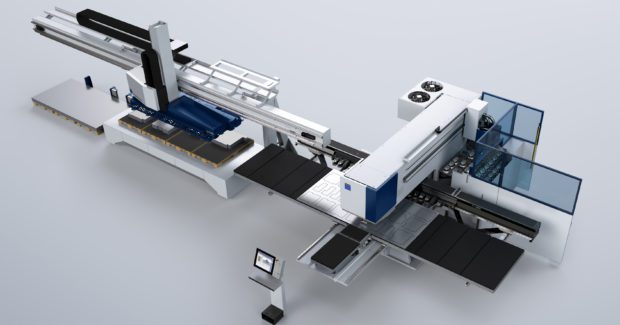

In other automation applications, TRUMPF offers the next generation TruPunch 5000 with the SheetMaster for loading and unloading. This highly productive punching machine offers increased productivity, exceptional process reliability and flexibility through new features that include retractable clamps, mobile control, and the new ToolMaster Linear for additional tooling capacity. With retractable clamps, the entire sheet can be used without limitations when nesting parts. This simplifies programming, since operators no longer must account for dead area and the entire sheet can be processed without repositioning. The machine also features smart punch monitoring, a unique technology that enables the machine to automatically detect a broken punch. Combined with additional smart functions to ensure every process runs reliably and consistently, the TruPunch 5000 is the new benchmark in high throughput and productivity.

https://youtu.be/0hS116dmc1E

The TruPunch 5000 is available with a working range up to 60 in x 120 in that can process material up to 0.312 in thick. With its innovative On-Demand Drive, the machine is capable of punching at a rate of up to 27 strokes/sec. These newly developed axis drives increase axis accelerations and rotation speeds to boost productivity. In addition to punching and marking, the TruPunch 5000 also offers a wide variety of forming options. The active die makes it possible to carry out especially high and large forms. To achieve its maximum potential, this new machine is made available with a variety of automation solutions, including the SheetMaster for loading and unloading parts. Enabling unmanned shifts, this system facilitates faster processing of orders, scratch-free sorting, and automatic sheet detection for higher process reliability. It can handle a large range of parts due to its programmable suction grippers and can also be combined with other automation components such as cars or material storage systems for maximum productivity.

AXOOM GmbH, Vincenz-Prießnitz-Str. 1, 76131 Karlsruhe, Germany, +49 721 7831 8922, [email protected], www.axoom.com.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6104, www.us.trumpf.com.