Multitasking Takes Center Stage

A wide range of Nakamura-Tome multitasking turning centers and strategies for machining precision parts was recently displayed by Methods Machine Tools.

Posted: May 14, 2016

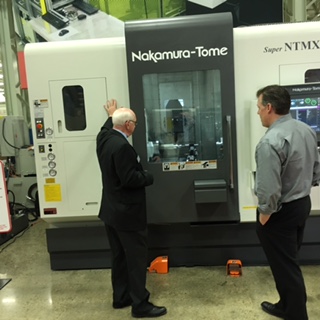

Methods Machine Tools, Inc. (Sudbury, MA), a leading supplier of innovative precision machine tools, 3D printing technology, automation and accessories, hosted their Nakamura-Tome Tech Days on May 11-12 at their corporate showroom and technology center in Sudbury. The two-day event featured the latest Nakamura-Tome multitasking turning centers and strategies for machining precision parts.

Attendees witnessed firsthand the wide range of new machines and multitasking solutions that were on display, coupled with informative, engaging seminars. Seven Nakamura-Tome machines were under power with live demonstrations:

- The new NTRX-300 ATC Machine is a multitasking turning center that featured complete parts machining in one operation, with a built-in load/unload automation system and advanced operator recognition management software.

- A NTJ-100 multitasking turning center with Twin Spindle, B-Axis upper Turret and Y-Axis lower Turret. It’s applications range from low to high volume lots of medical, aerospace, general job shop components and more.

- WY-100 Twin Spindle, Twin Turrets equipped with Y-Axis, rigid construction, 48 tools and up to 24 live positions. By offering highly capable features like pinch milling, drilling and turning, as well as unique “off center” interpolative functions that can be performed on both spindles, the opportunity exists to drastically reduce cycle times.

- The NTMX ATC machine is the world’s first Twin ATC Multitasking B-Axis lathe, with easy access and set up approach via two front ATC locations and the ability to change inserts without stopping the machine.

- NTY3-250 and NTY3, 3 Turret, 3 Y-Axis machines that dramatically outperform single-tool multitasking machines, allowing one-pass, complete turning/machining/finishing and reducing part cycle times.

- AS-200 LMYS Twin Spindle, Single Turret offers an upgraded long bed with sub spindle. The machine is equipped with a powerful milling drive, together with a high-speed, high accuracy C-Axis and 82 mm stroke Y-Axis.

In addition, industry leaders made presentations on both days that included:

- “Y Do you Need Y-Axis” by Rich Parenteau, the company’s director of application development and their Nakamura-Tome product manager, and Ken Corklin, their dealer technical support manager, addressed the benefits of using the Y-Axis in order to reduce the cost-per-piece and explained how the Y-Axis has some primary capabilities that make it extremely efficient and cost effective.

- “New NTRX-300 B-Axis Platform” by Parenteau provided an in-depth review of the features of this compact, heavy-duty state-of-the-art multitasking machining center.

- “New Smart-X Nakamura PC-Based Control” by Jundi Oyama, their Nakamura-Tome international sales manager for the U.S., reviewed the latest developments of the new “Smart X” operating system for PC-based control that is fully loaded with a Fanuc 31I-A5, 5-axis control and many new features that are ideal for even inexperienced operators, such as a user-friendly Icon Menu, Production Monitoring, Trouble Guidance and Operation Level Control Functions.

Attendees also toured one of the company’s recently established 3D Printing Labs that was set up by Ben Fisk, a former director of production at Pratt & Whitney. The lab in Sudbury has eight 3D printers around the perimeter, with four work stations in the middle that control all operations. These machines can print almost any kind of material and do blended printing of single pieces made of metal and plastic, rubber or other materials. They invite clients to come to the lab and create parts there or to buy the machines. The company provides soup-to-nuts training and support.

Lunch and refreshments were provided. “This was the perfect venue for manufacturing professionals to learn about the latest state-of-the-art technologies offered by Nakamura-Tome,” noted Parenteau.

Methods Machine Tools has been in operation for over 55 years as a leading supplier of precision machine tools, 3D printing solutions, automation and accessories, providing extensive applications engineering support, installation, parts, service and training through a network of large state-of-the-art technology centers and dealers throughout North America.