Improving Automation with Welding Information

By providing archived data that can be used to lower costs, a welding information management system helps improve the productivity and quality gains offered by automation. This technology helps shops make the most out of their investment in welding automation, increase their competitiveness in the marketplace, and improve their profitability.

Posted: May 9, 2016

Welding automation can help shops gain greater productivity, repeatability and quality in their operations, while also making it easier to manage costs. Finding a way to drive continuous improvements in these operations is the best means to expedite the return on investment in the equipment, while also positioning companies to be more competitive. Whether a shop uses fixed or flexible welding automation, implementing a welding information management system can be an important way for companies to be successful. Various types of these systems are available to track production data (e.g., deposition rates and arc-on time), weld process data and weld process features. Access to this information helps companies locate inefficiencies, identify and rectify missed welds, be alerted of any anomalies and determine the cause of weld defects – all factors leading to a more efficient and profitable welding operation.

FIXED AND FLEXIBLE AUTOMATION

Many industries rely on some form of automated welding, including oil and gas, automotive, construction, and both light and heavy industrial manufacturing and fabrication. Two types of automation systems are commonly used in these welding operations: fixed automation and flexible automation. The best choice depends on the needs of the application.

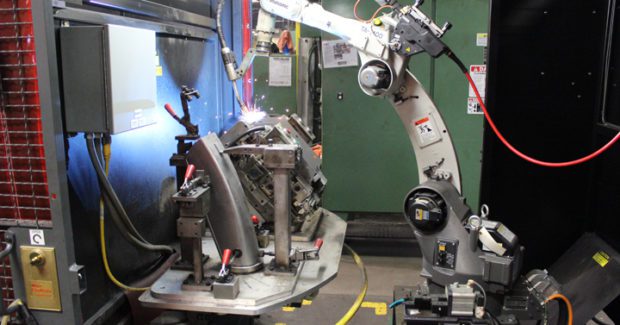

Flexible automation generally refers to a robotic welding system programmed to complete multiple welds in multiple locations and on multiple parts. In these systems, programmable logic controllers (PLCs) are sometimes deployed to handle the application variability. Flexible automation allows different fixtures and programs to be used, offering flexibility to a shop for welding multiple parts, but may require longer setup and cycle times. Fixed automation refers to a welding machine that is dedicated to making one specific part or family of parts, typically using a fixed welding gun or one that uses a single consistent motion. It offers higher throughput because parts are less complicated and requires fewer welds.

Both of these types of automation offer the benefits of increased productivity, higher weld quality, greater repeatability and reduced costs, as compared to semi-automatic welding. Both can also benefit from the implementation of a welding information management system, although the manner in which each realizes continuous improvements can vary.

MAXIMIZE THE INVESTMENT

Welding information management systems help ensure that companies maximize their investment in automated welding systems, whether it’s flexible or fixed. Numerous welding information management solutions are available, depending on what a shop wants to measure and what the goals are for the operation.

At a basic level, welding information management systems provide metrics that can be used to analyze the welding automation process and identify areas of improvement. These metrics include basic quality and productivity components such as arc-on time and weld count, deposition rates and weld parameters. Basic welding information management systems are considered passive because they do not intervene in the welding operation. Their data typically goes to the cloud for later analysis and action. These systems provide value by documenting, receiving and archiving information that can be used to make productivity improvements.

Another option is an advanced welding information management system that provides more sophisticated metrics and capabilities. This type of system directly communicates with the cell control, which provides a greater level of real-time weld process quality and weld defect detection. Compared to a semi-automatic welding process where the welding operator can make immediate adjustments to optimize parameters or correct issues, robots do not possess that capability. Their job is to execute the same weld at the same parameters every time. While capable, they are not typically programmed to identify or compensate for variations in fixturing or part fit-up that may occur, which can cause quality issues. Implementing an advanced welding information management system can provide real-time feedback and information in either fixed or flexible automation, but it is especially helpful for the latter.

For example, these systems monitor welding to ensure that the correct number of welds have been completed for the part, and to the proper duration and/or deposition. If the robot misses a weld or doesn’t complete it fully, the welding information management system alerts the weld cell control or supervisor so he or she can correct the issue immediately. This feature is especially important in flexible automation because of the variety of parts that can be welded in the same system. One part may have ten welds, while another part could have more or fewer welds. A welding information management system can track this, ensuring the right welds have been made on the right parts. The system will not deem the part successfully complete until all welds have been made, for the proper duration.

Advanced welding information management systems can also offer process control and analysis that help monitor and optimize primary process parameters, such as voltage, wire-feed speed and current, and compares them to upper and lower control limits. This comparison ensures welds are executed at the established and verified weld process settings throughout the robotic welding process. The systems detect out-of-process welds before the part moves upstream in the welding operation, which is especially important – the further upstream a defective part proceeds, the greater the cost to rectify the problem.

INFORMATION DIGS DEEP

Along with the benefits discussed above, advanced welding information management systems provide additional information that can help optimize robotic welding processes, including:

- Metrics that analyze arc current and voltage at higher fidelities, which help determine overall arc stability.

- Measurement and record of cycle time, particularly if arc-on time has been exceeded.

- Alerts to excessive use of wire, contact tips or gun liners so maintenance can be planned – vs. unplanned, which can interrupt cycle time and throughput for changeover of consumables.

- A visual interface, which allows the weld cell operator to pinpoint the location of weld defects on a part via colored indicators.

- Standardization of procedures and workflow.

- Reporting capabilities to validate that improvements are happening, to help drive continuous improvement.

These systems also allow shops to make annotations regarding downtime so that they can take action to correct it. Downtime capable of being tracked include planning for maintenance activities or noting when the robotic welding system is in teach mode or down for safety checks associated with the fixturing. This assessment allows companies to track where time is being lost and why.

Gaining the most out of both fixed and flexible automation systems isn’t a matter of chance. It involves careful planning, implementation and supervision. Adding a welding information management system can help improve the productivity and quality gains that automation can offer, while also lowering costs by providing and archiving data for companies to drive improvements — and validate the results. Simply put, this technology is one more way for companies to make the most out of an investment in welding automation, increase their competitiveness in the marketplace, and improve their profitability.

Todd McEllis is a product specialist and Vince Romano is the business development manager at Miller Electric Mfg. Co., 1635 West Spencer Street, Appleton, WI 54914, 920-734-9821, www.millerwelds.com.