Grading Turning and Milling Contest Skills

Engineers from CGTech will use VERICUT software to evaluate the accuracy of the NC programs created by students at multiple SkillsUSA/NIMS events.

Posted: May 13, 2016

CGTech (Irvine, CA) will be on hand at the National Leadership and Skills Conference (NLSC), June 21-23, 2016, to help grade multiple SkillsUSA/NIMS events related to Computer Numeric Control (CNC) machining. They will also be exhibiting ther latest version of VERICUT software in Booth S-149. More than 16,000 people will be participating in the event, including students, teachers and business partners.

The purpose of the CNC Mill, CNC Lathe and CNC Technician contests is to evaluate each contestant’s preparation for employment in CNC programming. In addition, it recognizes outstanding students for excellence and professionalism. The contest will assess the ability to write CNC programs, interpret prints, and measure/gage parts. Participants will also demonstrate theoretical knowledge of CNC machine configuration, setup and operations.

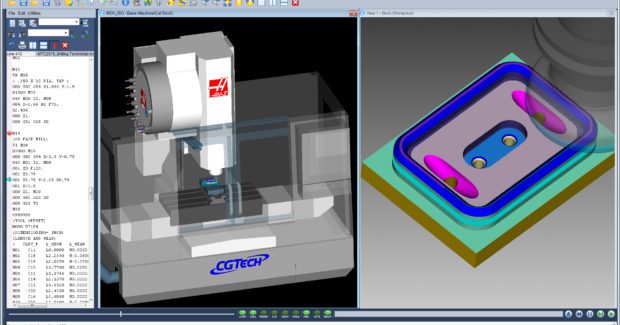

The company’s technical support engineers will use VERICUT software to evaluate the accuracy of the NC programs created while also ensuring the programs will run without violating safety standards or damaging machines. After each student’s NC program has been simulated, the virtual workpiece will be compared to the design model.

The software’s machine simulation detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, workpieces, cutting tools, and other user-defined objects. Machine movements can also be simulated while stepping or playing backwards in Review Mode.

CGTech specializes in numerical control (NC/CNC) simulation, verification, optimization and analysis software technology for manufacturing. Since 1988, their software has become the industry standard for simulating CNC machining in order to detect errors, potential collisions or areas of inefficiency. With offices worldwide, their software is used by shops of all sizes, universities/trade schools, and government agencies.

SkillsUSA Inc. (Leesburg, VA) is a partnership of students, teachers and industry working together to ensure America has a skilled workforce. The organization helps each student excel providing educational programs, events and competitions that support career and technical education (CTE) in the nation’s classrooms.

The National Institute for Metalworking Skills (NIMS; Fairfax, VA) was formed in 1995 by U.S. metalworking trade associations to develop and maintain a globally competitive American workforce. They set skills standards for the industry, certify individual skills against the standards and accredit training programs that meet their quality requirements.

NIMS operates under rigorous and highly disciplined processes as the only developer of American National Standards for the nation’s metalworking industry accredited by the American National Standards Institute (ANSI).

www.cgtech.com, www.skillsusa.org, www.nims-skills.org