Coolant-Through-The-Tool Drilling

Using the reCool attachment from Rego-Fix Tool on Suhner feed drilling units can increase surface cutting speed by 20 percent for higher chip removal rates and drastically reduced machine cycle time.

Posted: May 9, 2016

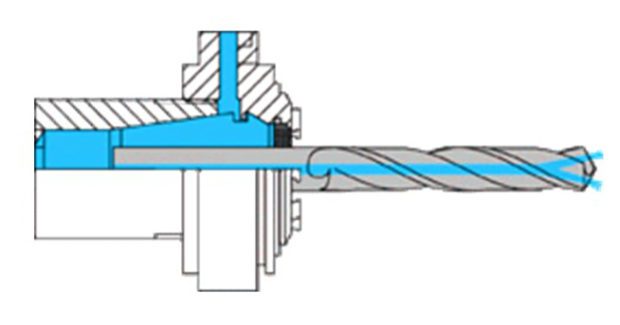

What is the main purpose for coolant application? It’s primarily for the lubrication and cooling of the cutting edge and to help facilitate chip evacuation. Rego-Fix® Tool Corporation (Indianapolis, IN) has launched a cost-effective and efficient attachment for the application of coolant-lubrication liquids through the tool, based on an ER collet nut, which is ideal for use on feed drilling units from Suhner Industrial Products Corporation (Rome, GA).

Optimizing the cooling and lubrication effect to help increase chip removal, tool life and performance requires the coolant-lubricant mix in direct contact with the cutting edge of the tool. For drilling operations, internal coolant becomes more and more essential. In the past, the application of an internal pressurized coolant-lubricant mix, especially for quill feed units, presented challenges and complications. The new approach engineered by Rego-Fix is called reCool®, where the coolant-lubricant mix enters the collet from the radial direction and then passes through the tool. It is very simple and effective. Based on this concept, Suhner adapted the reCool principle and designed attachments for the application of internal coolant liquids for its MONOmaster and MULTImaster families of quill feed drilling units.

Drilling with coolant through the tool applications typically allow for a 20 percent increase in surface cutting speed, which results in higher chip removal rates and drastically reduces the machine cycle time. This new system allows shops to retrofit Suhner quill feed units with internal coolant supply – even on existing machines – in a very clever, uncomplicated way that provides increased benefits in machine efficiencies and production time. Advantages to this system include:

- Simple retrofit for existing quill feed units

- Optimal cooling and lubricating at the tool

- Up to 20 percent higher surface speed

- Good chip removal

- Optimal lubrication for every tool

- No deflection or dissolving of coolant

Technical data for this system includes:

- Spindle speed up to 12,000 rpm

- Coolant pressure: 50 bar / 725 psi

- Flow of coolant lubricates internal bearings

- Used for internal and external coolant application

Suhner Industrial Products Corporation, Highway 411 South Suhner Drive, PO Box 1234, Rome, GA 30162, 706-235-8046, Fax: 706-235-8045, [email protected], www.suhner.com.

Rego-Fix Tool Corporation, 7752 Moller Road, Indianapolis, IN 46268, 317-870-5959, Fax: 317-870-5955, www.rego-fix.com.