Advanced Micro TIG Welding

The MAWA-300A Pulsed Micro TIG Welder from Amada Miyachi has a unique touch start feature to control and identify weld location when welding small coils and terminals, bus bars, and covered wires used in the automotive, medical, battery and electronics industries.

Posted: May 24, 2016

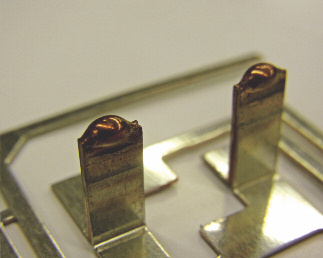

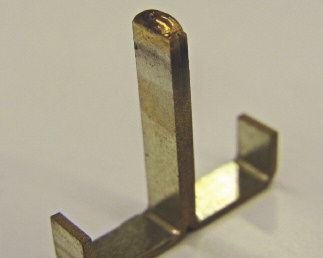

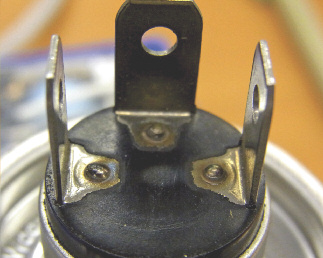

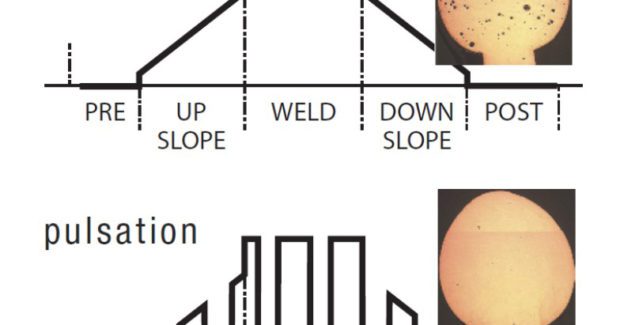

Amada Miyachi America Inc. (Monrovia, CA), a leading manufacturer of welding, marking, cutting and micro-machining equipment and systems, announces that their MAWA-300A Pulsed Micro TIG Welder now has a unique touch start feature that controls and identifies weld location, an ideal solution for welding small coils and terminals, bus bars, and covered wires used in the automotive, medical, battery and electronics industries. Its pulsation feature also significantly reduces porosity as part of a higher level of control that provides more consistent and reliable welds than competitors.

Durable and reliable, the high performance micro TIG welding power supply provides between 30 amps and 300 amps of output power and can weld conductive metals and dissimilar materials. Its monitoring function can readily identify process errors by checking the upper and lower limits of the current as well as the waveform envelope. A digital programming interface facilitates easy pulse form control, and the unit supports multiple weld schedules.

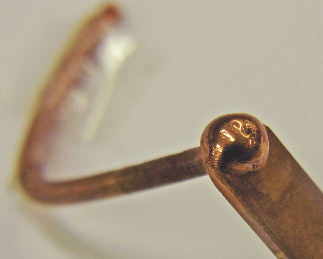

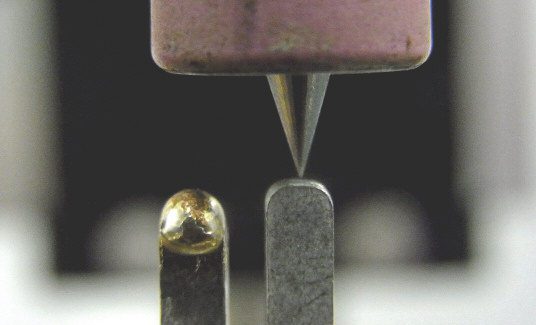

The new touch start feature is specifically designed for welding extremely delicate parts, where it is important to start with a low voltage rather than a high voltage that could damage the parts. With touch start, the tungsten electrode is lowered until it just touches the workpiece. The electrode then retracts and a low voltage arc is fired. The torch further retracts to the welding position and fires as scheduled. With this feature, the arc position is better defined and a lower start arc is required to generate the arc.

A full range of welding accessories for the MAWA-300A micro TIG welder is also supplied, including torches, electrodes, torch stands, and safety helmets and gloves. Amada Miyachi is a ISO9001 certified company.

Amada Miyachi America Inc.,1820 S Myrtle Ave., Monrovia, CA 91016, 626-303-5676, [email protected], www.amadamiyachi.com.