The Real Reel Handling Cart

This custom configurable cart Creform delivers difficult to handle reels and spools of wire and hose directly to the production floor, or for lineside part storage and replenishment.

Posted: April 9, 2016

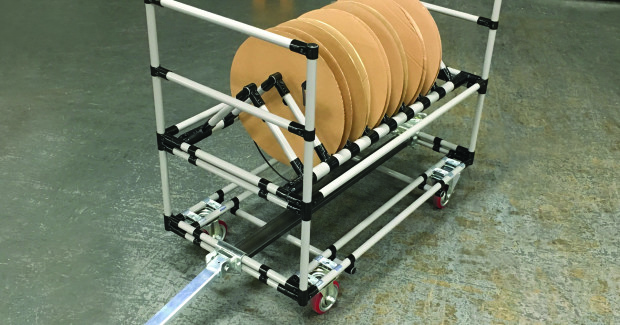

Some of the more difficult products to handle in a production environment are reels and spools of wire and hose. They’re cumbersome, usually big and are definitely awkward. Creform® Corporation (Greer, SC) has designed a cart specifically to hold reels and spools for delivery to the production floor, as well as being used for lineside storage for part replenishment. Although custom configurable, the cart pictured has ten adjustable positions making it easy to add, reduce or reposition the spools with basic hand tools. It also is configured for narrow reels but the dividers, used to keep product separated, can easily be moved to create wider bays. The dividers also prevent tangling and make for easy load/unload. The spools or reels are supported by their rim which also makes load/unload easy and helps protect the product that they carry.

The cart comes with four large diameter swivel casters which aid in the movement and positioning. The six-inch urethane wheels feature two swivels and two fixed casters. The cart shown measures 34 in W x 46 in H x 50 in L, but a wide variety of pipe and color options are available. This particular cart is designed to hold up to 600 lb and features a hitch for towing by a manual tugger of AGV. A tie-bar connects the front of the cart to the latch on the back making it easy to tow multiple carts at one time. The modular design affords the opportunity to add only the accessories that you want. Accessories include label holders, clip board hangers or tool holders to name a few.

The cart is constructed using the system of both 28 mm and 42 mm diameter pipe and joints. The critical long spans of the cart use the more robust 42 mm diameter pipe, while the 28 mm diameter pipe is used for the rest of the cart. a new series of structural metal joint sets for its unique 42 mm dia. pipe in a variety of shapes and configurations. The metal joints in this system, designated the LJ and the LEJ series, are complete joint assemblies for connecting 42 mm pipe most commonly used to assemble heavy-duty workstations, flow racks and carts. The metal joint sets are either nickel plated for anti-static applications or e-coated black for standard applications. They are available as LJ (42 mm / 42 mm) and LEJ (42 mm / 28mm) joint sets.

When choosing the appropriate joint, consideration is given to configuration, flexibility, strength, environment and cost factors of the structure. Many joints are well suited for industrial and logistic applications because of their durability, flexibility and reusability. The standard 42 mm metal joints are made of cold-rolled 10 ga steel. Components are joined together with special high strength socket head cap screw and nuts. The joints are designed to hold the nut so only a simple hex head wrench is required for assembly or disassembly. Joint assembly is easy as no special technical skills are necessary to build a structure.

Creform Corporation, PO Box 830, Greer, SC 29652-0830, 800-839-8823, Fax 864-877-3863, [email protected], www.creform.com.