Using AI in Smart Robotic Palletizing Operations

Yaskawa Motoman robots perform logistics that were not practical or could not previously provide a suitable ROI for part induction, bin picking, kitting, and random and unstructured depalletizing.

Posted: April 9, 2016

Yaskawa Motoman (Dayton, OH) performs unstructured depalletizing using Neocortex®, the flagship machine-learning software from Universal Robotics that is an interactive 3D learning platform which uses sensor input to learn and react in real-time providing extreme flexibility and adaptability. When combined with Motoman® robots, the applications expand the use of robots in logistics that were not practical or could not previously provide a suitable ROI. Applications now available for consideration include part induction, bin picking, kitting, and random and unstructured depalletizing.

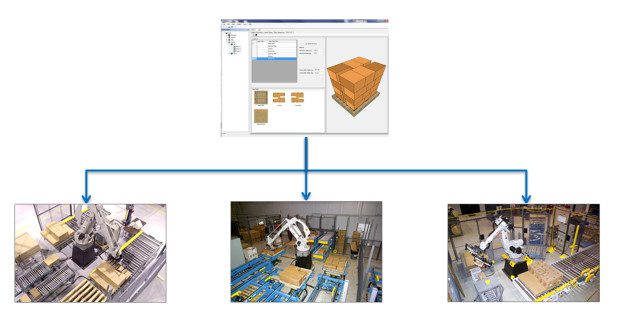

The robotic workcell can be used in end-of-line palletizing operations and in depalletizing operations for inbound logistics. For example, a MPL80 robot with PalletSolver™ software and two MH50 robots guided by Neocortex Unlimited Depalletization application software create a dynamic, interactive, palletizing/depalletizing operation for demanding environments. Users can create new pallet patterns from the cell HMI, as well as manually modify the pallet pattern at the depalletizing station simulating the on-demand environment of today’s packaging world.

“MotoSight 3D Spatial Vision, based on Universal’s Spatial Vision® Robotics, provides real-time 3D vision data to Neocortex, enabling our robots flexibility beyond what traditional machine vision guidance can provide for unstructured depalletizing,” said Roger Christian, the vice president of marketing and business development for Yaskawa Motoman. “The realization of handling a wide range of packaged consumer good products in various conditions and locations with Spatial Vision is a significant breakthrough and is an essential element to unlocking the robotics market in logistics, which over time, could rival unit sales only seen today in the automotive market.”

“Natural learning has a common pattern that’s demonstrated by all creatures,” added David Peters, the chief executive officer of Universal Robotics. “Neocortex mimics these learning patterns. We’ve dedicated the past four years to perfecting this software in material handling applications and integrating it with 3D vision from Spatial Vision Robotics. We’re confident of quick adoption by customers in this market space.”

PalletSolver is a revolutionary robotic palletizing software suite for Motoman robots. This dynamic package permits the setup of pallet patterns and robot motion on a PC so that the robot does not have to be taken offline for teaching. This system enables quick changeovers without stopping production to validate pallet patterns and allows faster integration of a palletizing system by making it easy to configure and set up. PalletSolver can easily be customized for complex robotic palletizing applications.

“This system redefines how robotic palletizing operations can be performed in the field. It offers operational excellence with intuitive tools for configuration, setup and production monitoring and control,” said Christian. “Its scalable architecture can handle single line and complex multi-line palletizing, as well as single and multiple workcells. We are very excited about this system.”

PalletSolver’s offline pallet pattern generation tool supports multiple robotic workcells, dynamic gripper zone management, constraints handling, unlimited SKUs and more. It has an intuitive graphical interface for configuring cell parameters and a guided step-by-step process for developing patterns. The system can directly import pallet patterns generated in the widely used TOPS or CAPE software, thus focusing efforts on building optimal sequences for the robotic build process.

“Manufacturing is challenged with constantly changing packaging and product parameters on the production line. This system intelligently addresses that challenge by handling cell constraints in the offline environment, allowing quick changeovers without needing to test patterns. Manufacturers can prevent a considerable amount of downtime by not halting production,” noted Shishir Rege, the product marketing manager of consumer product goods.

PalletSolver is available on both the DX100 robot controller and the PLC-integrated MLX200 platform.

Motoman Robotics Division, Yaskawa America, Inc., 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, Fax: 937-847-6277, www.motoman.com.