Die Springs Bring Longer Spring Life, Greater Safety

Impax Tooling coil and nitrogen die springs from Wilson Tool provide longer spring life, ensure compliance and offer optimum safety during high volume or standard production operations.

Posted: April 7, 2016

Wilson Tool International® (White Bear Lake, MN), the largest independent manufacturer of tooling systems for punch presses, press brakes, and punch and die components for the stamping industry, offers coil and nitrogen die springs from Special Springs to help fabricators improve stamping operations.

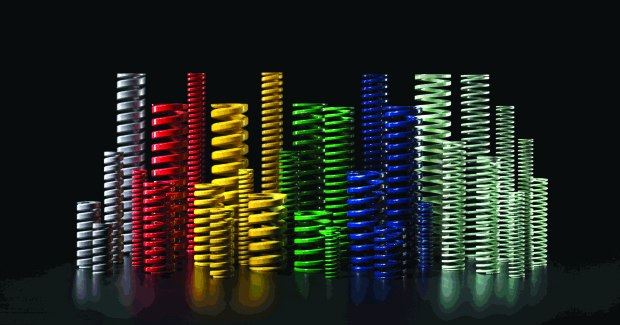

Part of the Impax Tooling Solutions line, die springs offer fabricators coil and nitrogen die springs designed for optimum spring life whether used in high-volume or standard production capacities. Coil die springs are designed and manufactured with high-quality materials to provide longer spring life. Each spring is individually color coded according to ISO standards to ensure easy duty rating identification. Sizes range from 0.375 in to 2.50 in diameter and work with all types of punch and die components.

Designed for high-production operations, premium nitrogen springs provide longer spring life, ensure compliance and offer optimum safety. These nitrogen springs are the safest on the market with regard to overpressure, overstroke and uncontrolled speed, which helps fabricators reduce the risk of injury and tooling damage.

In other tooling applications, Wilson Tool offers a complete line of press brake tooling called LVD Style. Available to the North American market, the LVD Style press brake tooling is made in the U.S., which means the company can provide shorter lead times and the fastest delivery available on this type of tooling to North American fabricators. Manufacturers can additionally benefit from fast issue resolution and quick tooling replacements by ordering directly from the White Bear Lake plant. LVD Style tooling comes standard with the following features:

- Punches and dies are laser hardened for increased life and durability.

- Dies are Nitrex® treated for optimal performance.

- LVD’s patented STONE® radius die design, which assures accurate bend angles along the full length of the bend and reduces friction between material and die, especially when used with the LVD Easy-Form® system.

- Die heights are designed to work with LVD’s Easy-Form system. Wilson Tool offers a full line of standard LVD Style tooling as well as special tooling upon request.

Since 1966, Wilson Tool has been a leading provider of punch presses, press brakes, and punch and die components for the stamping industry. Products are manufactured at the company’s world headquarters in White Bear Lake, as well as in manufacturing facilities in England, China, Brazil and Italy. Exacta product lines are manufactured in Toronto, ON. A network of sales engineers and international distributors operate in virtually every industrialized nation around the globe.