Agile Production of Crankshafts, Cylinder Blocks

MAG offers the Boehringer 221/226 Cx that is ideal for milling, turn broaching and turning new generation crankshafts, and SPECHT horizontal machining centers with integrated honing technology for boring cyllinder blocks.

Posted: April 16, 2016

The new Boehringer 221/226 Cx from MAG Automotive LLC (Sterling Heights, MI) is specially designed for the new generation of crankshafts for compact drive units with a progressive performance portfolio. This machine tool is a pioneer in higher milling performance for harder materials and crankshafts with optimized bearing diameter to reduce fuel consumption. Its compact design and optimum service accessibility allow integration into the shop floor with minimum space requirements. The Cx includes three types of modular machines for milling, turn broaching and turning. Each module uses a machine bed with a spindle, steady rest slide, same linear guide rails, the same ball screws, etc. Only the tool carrier differs, depending on the type of machining. This makes preventive maintenance easier and the shop only has to stock one spindle to be able to exchange it in case of failure.

The size of the spindle head has increased from size 8 to 11, with more solid spindle bearings that increase overall stability. Machining is precise from the first crankshaft on, without time consuming optimizations. The machine bed consists of an environment-friendly, recyclable mineral cast with high material damping. Integrated cast strips optimally conduct the occurring forces into the bed. The vertical bed slide reduces the moving load and the slant bed ensures an optimum flow of forces. High thermal inertia achieves dimensional stability during brief temperature fluctuations. Better yield and longer tool life can be expected through high stability that prevents chatter marks and improves surface quality.

These new CNC crankshaft machines feature a three-stage gear that brings more torque to the machine for higher productivity. “It was previously driven with a braked drive because the torque of the old two-stage transmission was insufficient,” explains Martin Billerbeck, the leader of rotary parts technology at parent company MAG IAS GmbH (Eislingen, Germany). One essential aspect of the machine’s design is operator friendliness and maintainability: a worker should be able to operate the machine optimally, with maintenance simplified by making all serviceable parts more easily accessible. For this reason, ease of use took priority in the entire process of cladding. “We place emphasis on functional machine design. What’s the use in having a nice sliding door without function?” asks Billerbeck. The sliding door opens by loosening three bolts so that the entire engine room is easily accessible from both the left and right. A lateral service entry allows maintenance personnel to quickly access all of the components. The cover can be moved without having to dismantle anything.

The machine interior working space is resistant against flying chips and optimizes chip fall so it is suitable for dry machining. Chips cannot accumulate and disposal is much easier using the generously dimensioned chip conveyors mounted beneath the machine. Flat recesses in the bottom plate allow the chip conveyors to be lifted above the bottom plate by using a handle. Removing the chip conveyor from the outside of the machine shrinks its footprint one meter shorter, to 4 m. The units in the compact assembly line can be arranged with only 800 mm of spacing. The energy container (fluid power and electrical cabinet) is centrally and compactly mounted on the rear of the machine and is more accessible. All control panels are vertically motor-adjustable according to the height of the machine operator for improved ergonomics. If a handheld terminal is used (e.g., for the portal) a corresponding plug is found directly on the control panel. An interface is available for the operating device of the loading manufacturer.

The Boehringer 226 CM is the longer machine version for the new 6-cylinder in-line engine crankshafts. It provides significant investment benefits for the operator, in addition to technical innovations that are productive and efficient, easy to operate and maintain.

In another automotive application, MAG has integrated honing technology into their SPECHT series of horizontal machining centers by developing an adjusting spindle with electromechanical drawbar. With this system, high precision can be achieved in many other tools besides honing by defined adjustments (blade compensation). Honing on the HMC offers a full-fledged alternative to a conventional honing machine, which includes all regulation and control algorithms for honing (including the pneumatic in-process measurement). Both the single spindle SPECHT and two-spindle SPECHT DUO now offer multi-layered advantages of honing technology on the same machining center.

Due to the permanent detection of the actual oversize after fine boring, the subsequent honing can be significantly shortened. This results in lower investment costs in lines with honing machining centers over a conventional honing machine, where the savings for investment and operation can reach 20 percent. Further advantages of honing solutions on an HMC include redundancy through parallel processing, scalability at production start-up, and easy reusability of the machine when changing products. This means a honing machining center can be reused later for other tasks apart from honing, if required. The processing results are impressive as well: cylindricities < 5 μm at cylinder bores are easily and safely accessible after honing. Due to the rigid HSK100 interface, in combination with fine boring in one clamping, the position and location of the cylinder bores after honing are also extremely precise.

Another automotive development relates to process changes in the coating of cylinder bores, where the thermal coating of cylinder running surfaces is introduced into some series applications at various automobile manufacturers. The reasons for these coatings are numerous and usually include reduced friction, increased durability, resistance to corrosion caused by poor fuel quality, better heat transfer that is essential for small turbocharged engines, and downsizing or reduction of engine block construction space for weight reduction. To improve the efficiency and robustness of the machining and coating process chain, MAG collaborated with the STURM Group (Salching, Bavaria) to create a turnkey production line that combines machining and automation with inspection, coating and cleaning. And the line is offered from a single source, with the individual process steps optimally and flexibly adjusted according to the individual requirements of the customer. (see Figure 1).

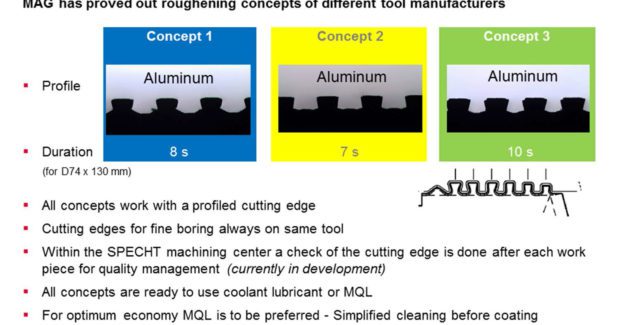

Bore surface activation that is necessary prior to coating can be done mechanically on a SPECHT horizontal machining center (see Figure 2). The two-spindle machining center SPECHT 500 DUO+ is developed especially for the supply industry. With the full flexibility of 5-axis machining, a pallet changer for runtime parallel loading, and the highest productivity through reduced chip-to-chip times by dynamic magazine discs, the 500 DUO+ does not leave any demand of machining out of consideration. An ergonomic runtime-parallel loadable chain magazine with large capacity meets the needs of a processing center in an ideal fashion.

For greatest efficiency, mechanical roughening is preferred and continuously refined. After coating, the finish machining of the cylinder bores can be done on the MAG machining center, either by fine boring or rough honing. For economic reasons, fine boring is expected to be the preferred solution in the future, though development efforts are still needed to get the tool life in an acceptable range. The finish honing of coated cylinder bores is also possible on the SPECHT (see Figure 3). With these areas of efficiency, robustness and flexibility, MAG and STURM offer a unique process chain.

MAG Automotive LLC, 6015 Center Drive, Sterling Heights, MI 48312, 586-446-7073, Fax: 586-446-5273, www.mag-ias.com.