Advanced Feed System Automates Fabrication

The Advanced Feed System from Scotchman increases productivity, decreases set-up time, reduces operator error and eliminates waste by turning a semi-automatic machine into a fully automatic production machine.

Posted: April 2, 2016

Scotchman® Industries (Philip, SD) features their Advanced Feed System that allows shops to increase productivity, decrease set-up time, reduce operator error and eliminate waste by turning a semi-automatic machine into a fully automatic production machine. When this system is coupled with a Scotchman circular cold saw, any operator can easily enter cut lists into the controller, then secure the material in the indexing clamp and hit start. That’s all there is to it. The Advanced Feed System automatically moves and clamps the material into position, then cycles the machine.

Operators can either manually enter dimensions into the controller or pull a cut list directly from the controller. Powered by TigerStop, this programmable controller stores up to 99 programs. Another option is downloading cut list information directly from a personal computer, which not only speeds production, but also reduces the chance of operator error. One-off cuts are easy too: the operator simply keys in the desired cut length in inches, fractions, or metric, and push start. The automatic stop moves to position. “The Advanced Feed System will cut production time in half, virtually eliminating set-up time. Now, operators no longer need to use a tape measure or set and adjust manual stops,” explains Jerry Kroetch, the president of Scotchman.

This system can be used as a programmable stop system or a fully automatic programmable push feed system with the optional material clamp. Shops can eliminate scrap by using the optional optimizing software: an operator can pull out any piece of material, even scrap material, and then enter the clear stock length into the controller. The system calculates how to best optimize the material for the highest yield.

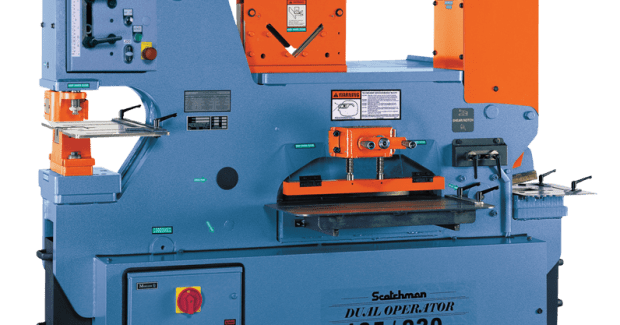

In other equipment applications, Scotchman offers several American-made, dual operator ironworkers that allow two operators to perform two different fabricating functions simultaneously, using 70 tons to 150 tons of punching power. The Tool Table design and wide variety of optional tools give these dual operators more versatility and flexibility than any other machine on the market. The two main features that set these dual operator ironworkers apart from others are:

- On all non-Scotchman dual operator models, the punch station must be used as one of the two functions. On the Scotchman, the punch can be used as one if needed, but it is not required.

- The Scotchman dual operators are designed with a hydraulic system that has two pumps to ensure full hydraulic pressure and full speed when two functions are running at full capacity.

For example, their DO 135/220/24M dual operator has four built-in features that include a 135 ton punch (1-11/16 in inside 1 in), a 6 in x 6 in x ½ in angle shear, a 24 in plate shear (1 in x 12 in, ½ in x 24 in) and a rectangle notcher. Combining these features with a large tool table for quick change of optional tooling – plus a best in the business, 3-year parts warranty – makes the DO 135/220/24M an industry leader.

Scotchman Industries, Inc., PO Box 850, Philip, SD 57567, 800-843-8844, Fax: 800-843-5545, [email protected], www.scotchman.com.