Using Metal-Cored Wire with Pulsed MIG to Weld Galvanized Steel

High strength galvanized steel is an excellent material to help automotive manufacturers build lighter-weight vehicles, but it can present some challenges that make it difficult to weld.

Posted: March 1, 2016

As automotive manufacturers seek to build lighter-weight vehicles capable of offering greater gas mileage – without compromising quality or safety – high strength, galvanized steel is becoming an increasingly common material option. This type of steel has a protective layer of zinc oxide on its surface and offers numerous benefits for automotive applications, including excellent corrosion resistance and high tensile strengths, even at thinner gauges. Fabricating more automotive parts with galvanized steel can reduce total vehicle weight by hundreds of pounds in some cases, which helps automotive manufacturers meet increasingly stringent requirements for vehicle fuel economy.

In particular, the Corporate Average Fuel Economy (CAFE) regulations make reducing overall vehicle weight a continuing issue for the automotive industry. The regulations, intended to improve the average fuel economy of cars and light trucks sold in the United States, were first enacted in 1975. Now the U.S. Department of Transportation and the U.S. Environmental Protection Agency are requiring the average fuel economy to be the equivalent of 54.5 mpg for cars and light-duty trucks by model year 2025. In addition to contributing to lighter-weight vehicles, using galvanized steel to design thinner, lighter parts can also result in cost savings for automotive manufacturers, since they can use less material for the job.

The properties of galvanized steel that make it such a good option in these applications, however, can pose some challenges in the welding process: there is more potential for burn-through due to the material’s thinness, and the zinc oxide coating can contribute to weld defects such as surface and subsurface porosity. Automotive OEMs can address these challenges by choosing the right filler metal and welding process. To date, metal-cored wire formulated specifically for the material paired with pulsed MIG welding has yielded positive results. The combination offers faster travel speeds at lower temperatures than welding with solid wire, helping improve productivity and efficiency.

THE PROS AND CONS OF GALVANIZED STEEL

Because high strength, galvanized steel has a protective layer of zinc on its surface, the material offers excellent corrosion resistance and high tensile strengths, even at thinner gauges such as 1 mm. Galvanized steel can also offer cost savings compared to using a base metal like aluminum, especially when the application calls for using a lot of the material. Because of these benefits, some automotive manufacturers are utilizing galvanized steel in the 1.6 mm to 4 mm range for components such as frames, engine cradles and suspension links, and using even thinner measurements for other areas of the vehicle. It’s also not uncommon to find components like auto body skins measuring as thin as 0.7 mm.

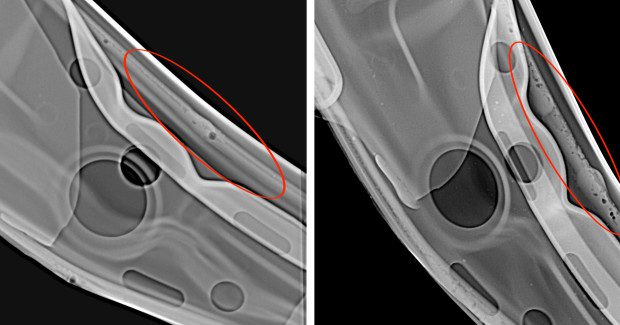

The potential for burn-through and porosity that can occur due to the material’s thinness and zinc coating pose risks for quality and productivity in automotive manufacturing – which can negatively impact a company’s efficiency, competitive edge and their profits. Porosity is a significant issue that is critical to address, since these weld defects can lead to catastrophic part failures. American Welding Society (AWS; Miami, FL) standards regulate the amount of surface and internal porosity allowed on galvanized steel. Determining the internal porosity of a part is typically a two-step process: an initial X-ray of the weld, followed by image analysis using contrast analysis to quantify the amount of porosity as a percentage.

As a rule, individual instances of porosity need to be separated by at least their own diameter and the total length of porosity (sum of diameters) should not exceed 6.4 mm inside any 25 mm (or 1/4 in inside any 1 in) of weld. The maximum diameter of any instance of porosity should also not exceed 1.6 mm (1/16 in). Internal porosity is generally limited to less than 25 percent of the area being inspected. If the amount of the defect detected in the subsurface of the weld exceeds the allowable limits for a given component, it leads to rework or scrapping of those parts. Travel speed directly impacts the presence of porosity generated during welding. The faster the travel speed, the faster the weld pool tends to freeze, which can be especially troublesome since zinc vaporizes at a much lower temperature than steel melts. This differentiation can lead to gas pockets becoming trapped (porosity) as the weld solidifies before the zinc gas can escape.

To compensate for these issues, automotive manufacturers often lower travel speeds, particularly when welding with solid wire. While this solution may address quality in a positive way, it negatively affects productivity. Slower travel speeds equal fewer welds and lower net throughput. It also can affect capital outlay and real estate requirements, and shift production bottlenecks.

In addition to porosity, the potential for burn-through is a common challenge with galvanized steel. Spatter – typically the result of the shorter arc lengths associated with constant voltage (CV) modes of welding – can also adhere to the part and the tooling, requiring post-weld cleanup and causing potential damage to the system. Also, the presence of silica islands in the weld, especially those that may break free after the e-coat or paint process, can lead to problems when welding galvanized steel. All of these potential issues can be costly: in time, money and lost products.

METAL-CORED WIRE AND PULSED MIG

Pairing a pulsed MIG welding process with metal-cored wire designed specifically for use with galvanized steel can help address or prevent many issues related to welding galvanized steel. In addition, this combination also yields significant speed and performance improvements compared to solid wire, due to the travel speed benefits inherent to metal-cored wire. To successfully weld galvanized steel, it’s essential to keep a balance in the time/temperature relationship. To put it simply: hotter and faster are the keys to overcoming many of the challenges when welding this material – benefits available with the pulsed MIG/metal-cored wire combination.

Metal-cored wire is a type of tubular wire consisting of a metal sheath filled with metallic powders, alloys and arc stabilizers. Compared to solid wire, this wire carries higher current densities at equivalent amperage settings, which means more weld metal can be put into a joint in less time. Because of these faster travel speeds, metal-cored wire is a common choice for robotic welding applications, like those often found in automotive manufacturing. To get the same weld quality with solid wire, much slower welding speeds and higher heat input would be required, increasing the potential for burn-through.

Advancements in metal-cored wire technology, specifically in regards to the wires carrying the AWS classification E70C-GS, provide significant advantages for welding galvanized steel. The formulation of these wires allows them to weld with a direct current electrode negative (DCEN) or straight polarity. The ability to operate in straight polarity provides some distinct advantages when welding thin gauge galvanized steel, including a softer arc penetration that prevents burn-through; an improved penetration profile; and sufficient arc energy to vaporize the zinc coating, which minimizes surface and subsurface porosity.

The new metal-cored wires formulated for galvanized steel are designed to weld at 40 ipm in robotic applications, compared to 23 ipm or 25 ipm for solid wire. The faster travel speeds and lower defect rates offered by the wire can help automotive manufacturers increase throughput and reduce cost for rework. These metal-cored wires also improve deposition rates, offer good gap-bridging capabilities and provide a deposit that maintains excellent ductility and impact toughness. As with other metal-cored wires, these wires also feature arc stabilizers that improve metal transfer from the wire to the weld. The smoother arc reduces spatter, so there is less time on post-weld cleanup.

The pulsed MIG waveform process optimizes these results by regulating the deposition of the wire across the arc at controlled intervals in the welding cycle. The power source switches welding output rapidly between a high peak current to a low background current to create the pulsing effect. The peak current then pinches off spray-transfer droplets and propels them toward the work piece. The combination of this action, along with the formulation of specific metal-cored wires for galvanized steels, helps control the pace at which the weld pool freezes, allowing the zinc vapors to escape more readily. In addition, the pulsed MIG process generates lower heat input than the standard CV process used to weld with solid wire, making it less likely to burn-through on thinner material.

A SOLUTION TO MAXIMIZE RESULTS

There are many important factors to consider when choosing a filler metal: the application, material thickness being welded, porosity requirements and finished weld quality. In many applications, new options in metal-cored wire designed for use with galvanized steel can help increase productivity, improve quality and maximize the benefits the material offers in automotive applications. Pairing these metal-cored wires with a pulsed MIG welding process provides additional benefits that can help manufacturers improve their welding operations and gain a competitive edge.