Powerful Simulation Maximizes Productivity and Profitability

Version 7.4 VERICUT CNC simulation software from CGTech provides faster processing speeds, longer tool life and increased part quality to continually optimize workpiece quality.

Posted: March 28, 2016

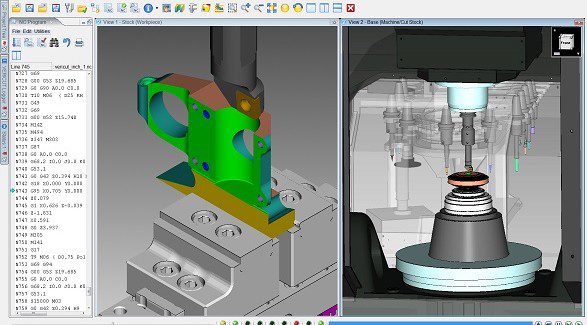

CGTech (Irvine, CA) released version 7.4 of their VERICUT CNC simulation software product that is used worldwide to simulate all types of CNC machine tools, including leading brands such as Mazak, DMG MORI, Makino, Matsuura, Okuma, Haas, and Heller. In addition to new features designed to make NC programmers’ jobs easier, nearly 500 customer-driven enhancements and software change requests have been completed in version 7.4. These updates utilize the latest technologies to enable faster processing speeds, longer tool life and increased part quality. Added features to the user interface simplify the most common user actions and significant developer hours have been invested to increase simulation speed by more thoroughly taking advantage of multiple processors and background processing.

“The enhancements in version 7.4 provide the speed organizations need to rapidly release new part programs to the shop floor, train new users, and continually optimize workpiece quality to ensure customer satisfaction,” said Bill Hasenjaeger, the product marketing manager at CGTech. “Changes to how users interact with VERICUT further improve its workflow and simplify day-to-day NC programming and simulation use. We have had extensive opportunity to understand our customers’ NC simulation challenges. This release increases the ability of manufacturing engineers to simulate the entire CNC machining process in order to produce better results and reduce the time spent in the programming and machining cycle. VERICUT is constantly refined to provide the flexibility and tools our customers require. We are committed to continually introducing technology to automate manual tasks and increase productivity and throughput.”

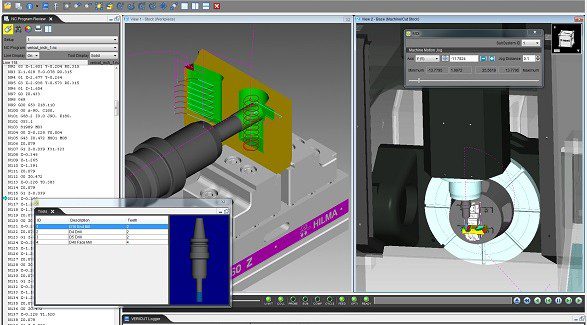

In version 7.4, the first thing a user will notice is a Welcome Screen that automatically displays when first launching a VERICUT session to provide access to commonly used first actions in a session. The user interface continues to get more customizable. The VERICUT desktop is enhanced with a new docking method enabling the desktop to be configured in the most efficient manner. The new docking method is very flexible and provides a high level of customization possibilities. Additionally, the Status window is completely redesigned for better viewing, customization and size. The Status window information is divided into Information Groups, each containing a specific list of information. The popular “Favorites” feature, added in version 7.3, has now been enhanced to automatically read all sub-folders in a directory.

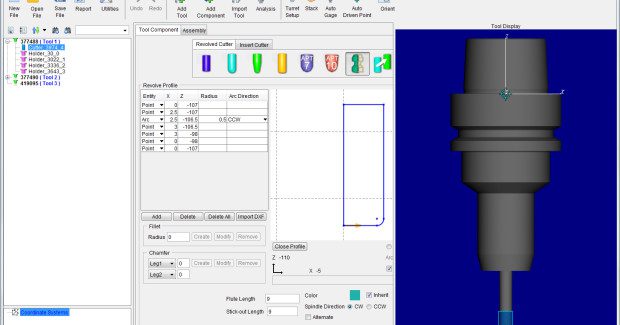

Tool Manager’s desktop and user interface is redesigned to enable easier user interaction. A new Tool Bar located at the top of the Tool Manager window consists of a combination of icons and pull-down menus providing easy access to all features needed to create and maintain tool libraries, create/modify tool assemblies, import tool assemblies and create or import OptiPath records. Also, in the Tool List, tool components now have a Parent/Child hierarchy allowing for better tool assembly management and modification. All Tool Definition windows have been re-designed to make tool definition easier. Version 7.4 ships with a library of common tools, making it very quick and simple to add new tools to a simulation session. Other new features include:

- New interfaces are available for integrating VERICUT with Creo Parametric 3.0, CAMWorks, and SolidWorks.

- Interfaces are available to nearly every major CAM system and are updated with each release.

- Seamless connectivity with Kennametal NOVO™, Iscar IQCloud™, and other tooling suppliers via the Machining Cloud™.

- Kuka Robot Language (KRL) is supported. OptiPath now automatically works through multiple setups.

- Selecting a tool from the new Reviewer Tool Menu automatically sets the “Start” and “End” points of the simulation.

- NC program syntax is checked automatically when a file is opened.

The new module Force™ is a physics and mathematics-based modeling software designed to optimize machining rates for machined parts within aerospace, automotive, industrial and other markets that utilize automated machining. Force determines the optimum speeds for a cutting process and makes the CNC machine cut in the most efficient, fast and reliable way, based on the type of material being cut. It is particularly suited to the processing of tough materials like hardened/stainless/alloy steels, Inconel and titanium, which are commonly used in mold/die and aerospace part production.

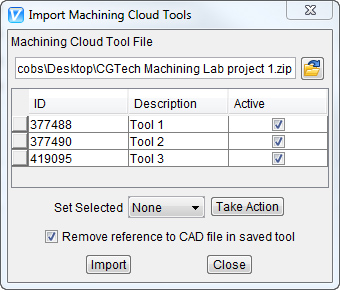

CGTech has also joined MachiningCloud to announce an enhancement in the MachiningCloud whereby VERICUT customers can import an entire tooling package into VERICUT in one simple step. Verification and simulation software is used to detect CNC programming errors, as well as potential collisions and areas of inefficiency. MachiningCloud is an independent provider of CNC cutting tool and workholding product data. New to version 7.4, after defining a tooling package on the MachiningCloud, users can directly download all the tool assemblies within the package and use it within VERICUT with significantly fewer steps compared to manually configuring a tool for use in a simulation session. The process is simple:

1) Build a MachiningCloud job containing your tool assemblies;

2) Export the job downloading it to your local computer;

3) From within VERICUT, click once to import all the tools from the job;

4) Simulate using your tool assemblies just created in the MachiningCloud.

“This upgrade eliminates manual steps saving time and further increasing efficiency in the simulation process for their customers using the MachiningCloud,” explained Christophe Rogazy, a cloud evangelist for MachiningCloud. “VERICUT users don’t want to do duplicate work to create tool assembly models for simulation if the tool geometry already exists,” added Hasenjaeger. “MachiningCloud makes OEM tool geometry easily available for part program simulation, and our connection makes it easily accessible to our users, with simulation-ready tool models representative of the commercial cutting tools they’re purchasing and using every day.”

CGTech, 9000 Research Drive, Irvine, CA 92618-4214, 949-753-1050, Fax: 949-753-1053, [email protected], cgtech.com.