Powerful Machining Software

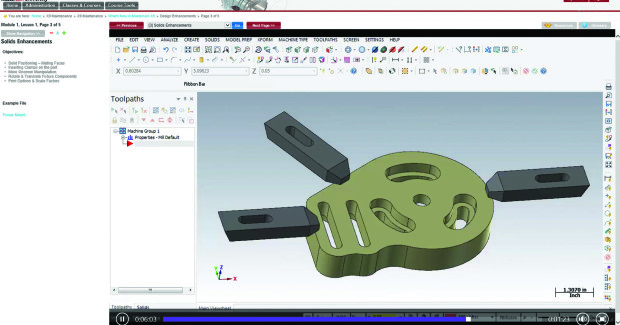

Dynamic toolpaths in Mastercam X9 not only calculate the area where metal will be removed, they also account for the changing condition of the material throughout various stages of machining.

Posted: March 29, 2016

CNC Software, Inc. (Tolland, CT) offers powerful Mastercam X9 machining software with Dynamic Motion improvements, Multiaxis enhancements, and many Design and System features to make programming easier. Dynamic Motion toolpaths follow a proprietary and sophisticated set of rules that take into consideration a broad data set. To create the most efficient cutting motion possible, Dynamic toolpaths calculate not only the area where metal will be removed; they also take into account the changing condition of the material throughout various stages of machining. Dynamic Xform can switch between gnomon manipulation and geometry manipulation mode at any time without having to reselect geometry.

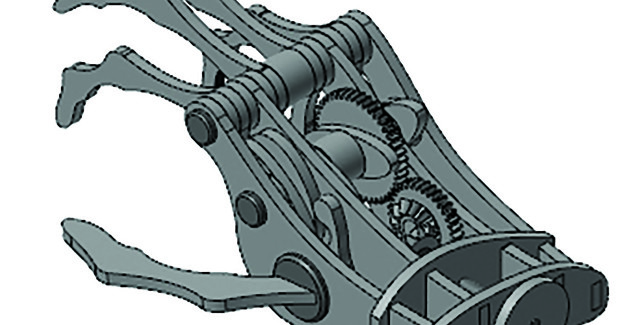

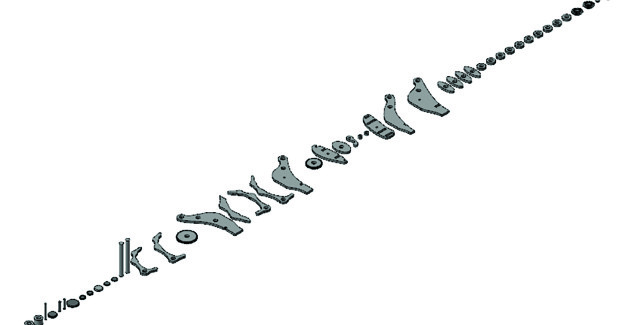

Solid Disassemble is a new Model Prep function that takes an assembly and lays each body out in a single pane. With Mastercam X9, the associativity between solids and toolpaths is greatly improved. When bodies are edited, only the toolpaths directly affected by the change in the solid body are marked dirty. The new Multiaxis Link ensures reposition moves between 2-axis through 5-axis operations are safe and collision-free. Multiaxis Link is an operation that takes a list of toolpath operations and a safety zone shape as input. Mastercam X9 introduces improved processing logic for advanced Multiaxis toolpaths. Select Multiaxis toolpaths now process in the Multi-Threading Manager, streamlining the 2-axis through 5-axis workflow experience. Other features in Mastercam X9 include:

- Preview Toolpaths support for select Mill operations to see results before closing the toolpath parameters dialog.

- Surface High Speed Hybrid now supports dedicated flat processing, making Hybrid even more intelligent and efficient.

- The efficiency of the 3D HST Rest Roughing Linking has been improved. The moves are closer to the model, eliminating costly excessive air motion.

- Mill Tooling introduces two new tool types, as well as changes to two existing tools.

CNC Software also announced that Mastercam University, their online learning tool that gives both students and experienced users alike 24/7 access to Mastercam training materials, is providing free copies of their Mastercam X9 Update course to Maintenance customers. This course is designed to help shops understand the new features in the Mastercam X9 release. Some topics that are covered in the Maintenance course are:

- Geometry – 2D bounding box, level and WCS modeless dialog, selecting geometry by level.

- Design – Dynamic transform, Gnomon manipulation, translate/rotate, select all entities.

- Solids – Solid positioning, mating faces, inserting clamps, rotate & translate fixture components.

- Offset – Xform offset, offset contour, analyze distance, create arc polar.

- Mill – Contour, lead in/out, solid chains, Backplot verify options, Verify / Mastercam Simulation.

- Toolpath – Peel Mill, Dynamic Motion, 2D HST Blend, center start cut direction, extend entry/exit.

- Tool – New tool shape/types, Barrel, Threadmill, Slot Mill with new upper corner radius control.

Mastercam University is online video training that lets shops learn at their own pace, their own time, and from experienced trainers. These online classes can help shops get up-to-speed quickly, keep their skills sharp, or even prepare for official Mastercam Certification. Mastercam University is open to anyone with Internet access and can be purchased through Authorized Mastercam Resellers.

CNC Software, Inc., 671 Old Post Road, Tolland, CT 06084, 860-875-5006, www.mastercam.com.