CAM for SolidWorks 2016

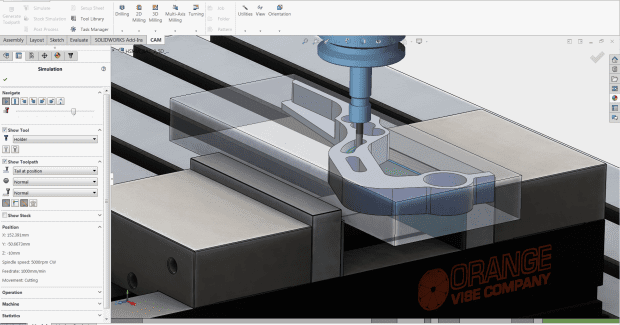

The newest version of HSMWorks from Autodesk fully integrates CAM solutions into SolidWorks 2016.

Posted: March 29, 2016

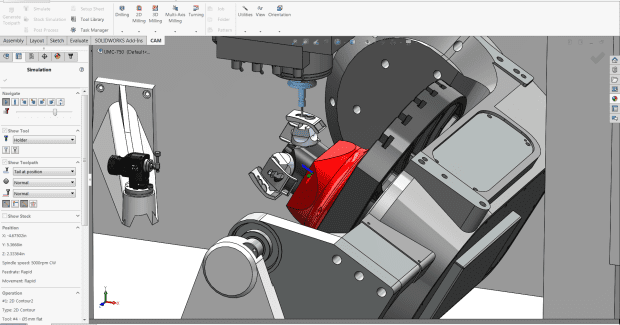

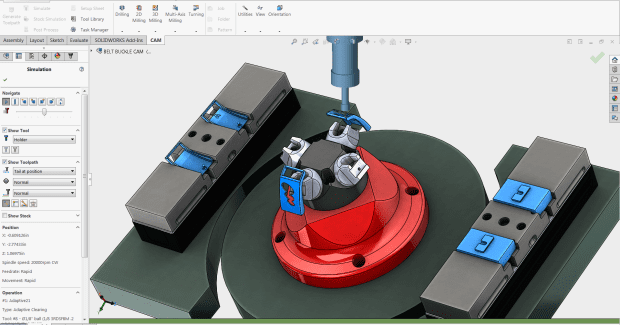

Autodesk, Inc. (San Rafael, CA) offers the newest version of the family of HSMWorks products, their fully integrated computer aided manufacturing (CAM) solutions that support SolidWorks 2016. HSMWorks and HSMXpress 2016 are part of a broader portfolio of advanced manufacturing solutions from Autodesk, including Inventor HSM, CAM capabilities within Fusion 360, Delcam products, TruNest and TruLaser products and Factory Design Suite. HSMWorks Professional 2016 supports 3+2 strategies for CNC milling machines as well as turning support for CNC lathes. HSMWorks Premium 2016 includes all of these capabilities and adds simultaneous 5-axis machining. HSMXpress 2016 is a free product that provides 2.5-axis milling. Both solutions provide users of SolidWorks software with powerful integrated CAM tools that improve productivity of their design to manufacturing workflows.

“We are committed to providing ongoing support for all of our HSM CAM products, regardless of our customers’ chosen design software,” said Al Whatmough, product manager for Autodesk HSM CAM products. “This latest release gives SolidWorks users access to a truly integrated CAM solution.”

In addition to supporting users of SolidWorks 2016, key highlights of this release include:

- User Experience Improvements, including silhouette sketch, advanced notes visualization, improved defaults management, Albrecht and Maritool holder libraries and advanced WCS definition in-job setup.

- Toolpath Generation Improvements such as morphed spiral, rest machining for turning, stay-down linking and even step downs in adaptive clearing, engrave strategy, semi-automatic chamfering and automatic holder detection for adaptive clearing.

- Post Processing Additions, including a CAMPlete interface, generic Haas UMC 750, generic Haas Mill/Turn, factory tested Datron and generic Siemens turning.

Autodesk, Inc., 111 McInnis Parkway, San Rafael, CA 94903, 415-507-5000, www.autodesk.com.