Two-In-One Milling

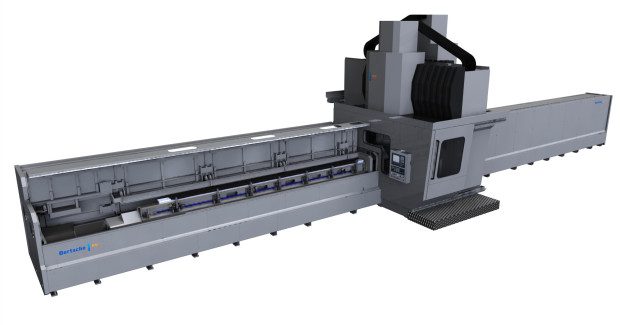

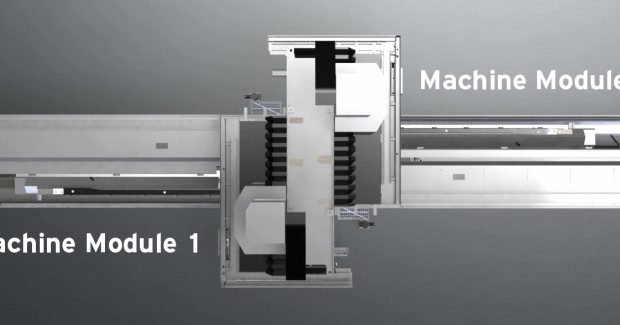

The Dual P5 Mill from Bertsche links two independent machines with CNCs and two 5-axis machining modules with separate machining chambers to process two different parts at the same time in a single footprint.

Posted: February 15, 2016

An aerospace supplier was faced with the choice of either building a new facility to house two new milling machines or splitting their production between two manufacturing sites. Bertsche Engineering Corporation (Buffalo Grove, IL) developed the new Dual P5 Mill that offered this supplier the throughput productivity of two machines with the floor space footprint requirements of only one machine, thereby saving them the cost of building a second facility and moving all of the production to a larger plant. The Dual P5 Mill provides all of the benefits associated with having two machines: independent but linked CNCs, two 5-axis machining modules (A-side, B-side) each with separate machining chambers, and the ability to machine two different parts at the same time – yet the overall machine is nearly the same size as a previously supplied single 5-axis P5 Mill.

Based on daily production requirements, the Dual P5 Mill is operated A-side only, B-side only, or A- and B-side together. Twin integral vacuum fixture tables are designed to accept a variety of different vacuum workholding fixtures that can be quickly changed at a moment’s notice with a high degree of repeatability. To assist the operator loading parts, each table has retractable datum surfaces that swing into place to edge-locate parts and then swing back down when machining. Thick-walled composite structures (up to 0.625 in) are milled, scalloped, edge trimmed and drilled on all sides. High accuracy hole patterns and datum holes are drilled for determinate assembly and then probed for accuracy. Parts are machined complete in a single setup and manufactured one-off to meet user ship-set kitting requirements.

With the growing trend towards cutting composites wet, flood coolant cutting was added and composite debris is flushed into a full bed length flume system. Flood coolant is constantly circulated throughout the machine for greater machine thermal stability. High volume mist collection hoods, integral to the machining compartment, collect and vent mist. A special sealing system is employed on linear ways to protect precision surfaces from very aggressive (detergent type) coolant fluids that must be used with composite materials. Multiple temperature sensors on the bed and X-axis slide accurately capture data for dynamic thermal compensation. To reduce the amount of filtration media, coolant is continuously filtered using a cyclonic filtration system. Operating benefits include:

- Very efficient use of available floor space, with twice the productivity compared to a previously installed machine and easier to manage work area.

- Labor cost savings and lower operating costs due to greater efficiencies.

- Operate as single or twin machine with flexibility to better match daily production demands to available machine capacity.

- Longer tool life due to wet cutting composites and better dust management air quality through wet cutting.

- High response 2-axis head and spindle; thermal growth control and thermal growth compensation.

- In-machine probing, calibration and position verification (bore ring, sphere).

- Part drying provided as part of post machining operations.

Bertsche Engineering Corporation, 711 Dartmouth Lane, Buffalo Grove, IL 60089, 847-537-8757, Fax: 847-537-1113, [email protected], www.bertsche.com.