The Right Filter Makes a Difference in Weld Fume Management

Removing the fumes from the area is only the beginning of the process. How you filter the fume is just as critical to achieve successful results.

Posted: February 25, 2016

Properly managing weld fumes is an important part of maintaining a safe and comfortable environment for workers in welding operations. A fume extraction system is one solution, but removing the fumes from the area is only the beginning of the process. How you filter the fume is just as critical to achieve successful results.

There are three main components that work together to make any fume collection system efficient: the fan and blower package, the housing for the filter, and the filter media itself. The airflow rate at the end of the arm in the capture zone is an important value to understand, as it has a big effect on the ability to remove welding fumes from the breathing zone and to send those particulates to the filter to be removed from the air. However, the filter media is the key component of any system.

Investing in the best equipment but pairing it with the wrong filter media can reduce your expensive fume extraction system into nothing more than a dust collector. Maximizing the performance and efficiency of a fume extraction system involves two key factors: choosing the right filter media for the job and performing regular maintenance on the system. Selecting the right filter and performing proper maintenance will improve the overall function of the fume extraction equipment — resulting in better airflow and air quality in the work environment and lower costs.

CONSIDER HOW THE FILTERS LOAD

All filters are not created equal. Different filters provide varying levels of performance. As a fume extraction system is used, the filters in the system become “loaded” with fume particles and dirt. As the filter loads, this creates more resistance for airflow and performance can decrease. Depending on the type and design of the filter media, some filters have significantly decreased airflow within minutes once welding starts.

https://youtu.be/PSAvRaD5TW8

This can pose problems in the work environment because a filter that provides poor performance and quickly reduced airflow requires the fume extraction hood be kept very close to the part in order to extract fume, perhaps 6 inches to 8 inches away. Compare that to filters that offer better performance, which allow the fume extraction hood to be kept 12 inches to 16 inches away. A reduction of 50 percent in this space due to a lower performing filter means the operator must constantly stop to adjust the extraction hood over the weld — adding time to the welding process and decreasing efficiency. Some welding operators may even stop using the fume extraction system completely if this process becomes too cumbersome.

Filters with the highest efficiencies and the lowest pressure drops typically capture fumes better, last longer and have lower operating costs. Pressure drops refer to the filter’s resistance to airflow and the amount of pressure it takes to pull the air through the media of the filter. Maintained airflow rates and efficient filters help protect workers from fumes in the breathing zone over a longer period of time for more effective fume removal. Also, a more effective system is more likely to be used by the operator, and the ability to keep the fume hood farther away from the weld minimizes the impact on productivity and efficiency.

NANOFIBER FILTERS

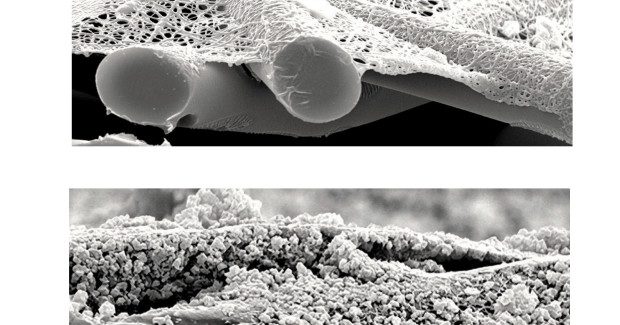

Filters that utilize nanofiber technology have a very thin surface layer that offers high efficiency in filtering the smallest of weld fume particles. This thin layer also offers low-pressure resistance to airflow, which allows the high fume capture efficiency to be maintained for a longer period of time. Some filters have a thicker surface treatment, which can provide high fume capture efficiency but also has much more resistance to airflow. As soon as these types of filters begin loading, the airflow measurement in cubic feet per minute (cfm) starts to drop significantly.

In addition, nanofiber filters are surface loading, versus depth loading. This means the nanofiber captures particles on the surface so weld fume accumulates on the top of the filter without penetrating into the media itself. This allows for the particles to be released much easier during the cleaning process, which is often done internally via a self-cleaning process in the fume extraction system with compressed air.

Surface-loading nanofiber filters, like those in the FilTek™ XL filter series, provide high-efficiency cleaning and also offer high loading for longer filter life and the least amount of resistance to airflow. FilTek surface-loading filters hold up to six times more dust given the same pressure drop across the filter media, compared to common cellulose filters. This results in a high level of fume capture at the source, for optimal breathing zone protection.

Depth-loading filters have high restrictions to airflow, reducing system performance versus FilTek XL filters. Using filters designed specifically to capture welding particulates increases both effectiveness and efficiency in removing welding fume particulates from the welding environment.

PROPER CLEANING AND MAINTENANCE

Proper fume extraction system maintenance and filter cleaning are also important factors in achieving optimal performance. Many systems include an internal self-cleaning mechanism to clean filters with clean, dry compressed air. Avoid cleaning filters manually, such as with an air gun, which can damage the filter media and cause poor performance.

The weld fume particles removed during the cleaning process also must be properly collected and disposed of, which is a critical part of the process to avoid distributing the fume particles back into the environment. Pay attention to the indicator lights or gauges on the fume extraction system. These alert you to when the filter has reached maximum loading capacity and it needs to be cleaned or replaced. When you go through the proper cleaning process and a filter still no longer cleans well, it’s time for a new filter.

OPTIONS FOR KEEPING IT CLEAN

Having a good filter and conducting proper maintenance on that filter keeps a fume extraction system running as it was designed. No matter what type of fume extraction system you install, the filter media matters. Choosing a nanofiber filter will not only clean the air, but also lower operating costs and save on energy consumption. Airflow is minimally affected with the correct nanofiber filter, ensuring that your system is not straining through a clogged filter and instead is providing consistent extraction at the workstation.