Synthetic Gripper for Complex, Sensitive Workpieces

The RRMG Synthetic Gripper 3 from Röhm uses free-form surfaces that adapt to different workpieces geometries, whether they be round or prismatic in shape.

Posted: February 4, 2016

Further expanding its broad selection of end-of-arm tooling for any robot in any industry, Röhm Products of America (Suwanee, GA) introduces the new, customizable RRMG Synthetic Gripper 3 that brings 30 percent more clamping force to large workpiece handling than its predecessor. Perfect for the secure gripping and clamping of complex, sensitive parts, the lightweight, yet robust RRMG has jaws with free-form surfaces that adapt to different workpieces geometries, whether they be round or prismatic in shape. The RRMG has an optimized structure with reinforcements for maximum rigidity and long service life. It can perform up to 16 million gripping cycles without experiencing wear or requiring maintenance. For maximum process control and automation, users can add optional position monitoring to the RRMG via installable sensors.

Available in two sizes with gripping forces of 80 and 152 (N), the RRMG can be customized by developing these grippers around the 3D workpiece models provided by customers. The company also relies on selective laser sintering to manufacture these products. RRMG grippers, along with the company’s swivel units and tool changers, easily add increased reliability, productivity and profitability to automated manufacturing processes.

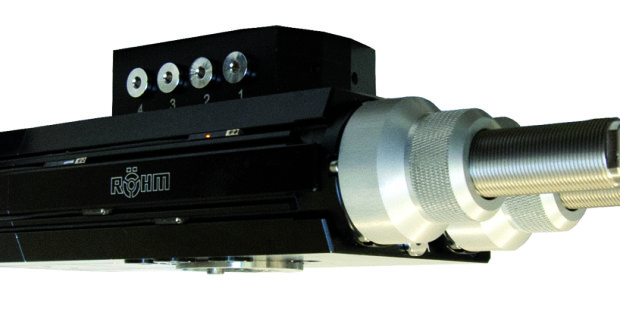

Röhm also offers their new RSP-MV Swivel Unit that provides smooth rotation, fast cycle times and high process reliability. The compact unit features mid-position locking and an innovative bumper concept that enables smooth, fast swiveling from the middle and end positions without the need to first vent the piston chamber. In addition, end and middle positions can be adjusted by ± 3 deg for tolerance compensation. Fine adjustment of dampers at end and middle positions provide compensation for varied workpiece geometries. Exact swiveling position is determined using up to six integrated magnetic sensors, reducing waiting times. The unit’s high torque over the entire swiveling range, in addition to end-position bumper adjustment for adaptation to the moment of inertia, also contributes to cycle time reduction.

Through the included S7 programming module, the RSP-MV Swiveling Unit can be integrated directly into existing program flow with a simple software handshake and put into operation immediately. Once it is installed, the RSP-MV can reach up to 10 million swiveling cycles without maintenance. It is available in three sizes with different configuration variations.

Röhm has also launched the DURO-TA XT key bar chuck that utilizes an ideal combination of weight reduction, compact design and workpiece accessibility and flexibility. This new design enables maximum utilization of a machine tool’s potential while also allowing clamping of higher workpiece weights. Through the use of extended and easily detached guideways, the clamping range of the DURO-TA XT has been doubled and made it more flexible to use. The chuck makes it easy to quickly change between large and small workpieces, which reduces set-up times and costs. Through the direct mount on the base body, the guideways guarantee extremely high rigidity, stability and protection from dirt and dust.

A weight reduction of up to 75 percent compared to conventional chucks reduces energy costs and minimizes spindle wear for even further cost savings. The manual chuck’s design also minimizes interfering contours to increase flexibility. In addition to boosting machine utilization, productivity and cost effectiveness for manufacturers, the DURO-TA XT supports Röhm’s global economic and ecological responsibilities as a partner of the VDMA Blue Competence initiative.

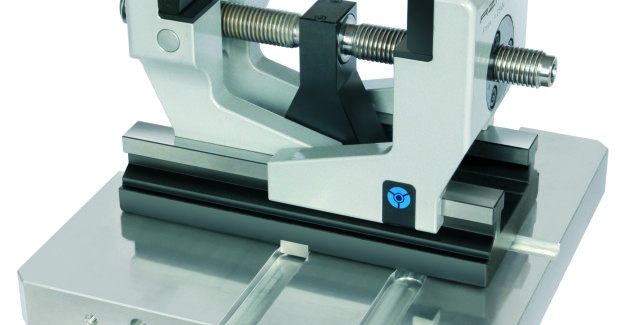

Röhm has also developed the Power-Grip zero-point clamping system to help manufacturers minimize machine downtime due to workpiece clamping. A user-friendly palletization system, Power-Grip provides an effective means to increase productivity by streamlining set ups. As a modular system, Power-Grip meets manufacturers’ demand for customizable solutions to maximize machine utilization. It reduces both the number of set ups required per part, as well as allowing set up to take place outside of the machine, thus eliminating downtime.

In addition to boosting productivity, the Power-Grip provides the added benefit of allowing a workpiece to proceed through multiple machining processes without losing its zero point. The system uses sturdy, corrosion-resistant hardware that makes it suitable for all machine environments, allowing it to be transferred from machining to electrical discharge machining (EDM) to measurement and inspection, all while maintaining excellent accuracy. Power-Grip’s cushioned, conical centering with a leveling system achieves accuracy of ± 0.002 mm, even with thermal changes. This clamping system can be seamlessly incorporated with a multitude of Röhm standard clamping devices, allowing for easy and flexible integration.

Röhm Products of America, 2500 Northlake Drive, Suwanee, GA 30024, 770-963-8440, Fax: 770-963-8407, www.rohm-products.com.