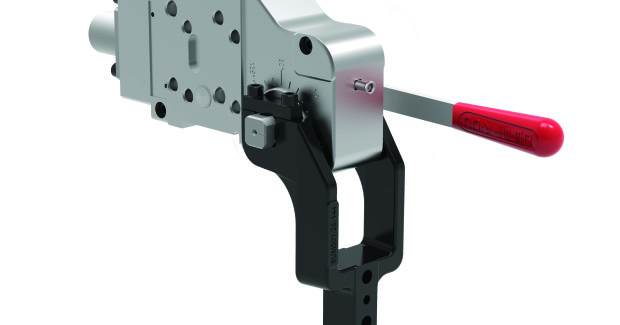

Manual Power Clamp for Prototype Fixtures

The 52H-3E adjustable manual power clamp from DE-STA-CO has a completely closed aluminum housing that protects the inner mechanical parts from weld splatters.

Posted: February 4, 2016

With the new 52H-3E series, DE-STA-CO (Auburn Hills, MI) offers a very individualized, adjustable manual power clamp primarily for prototype fixtures. These manual power clamps are available in two sizes: 50 and 63. They have a completely closed aluminum housing that protects the inner mechanical parts from weld splatters. The opening angle is close to infinitely variable with adjustments from 0 deg to 135 deg. An Allen key is used to open the retaining mechanism and to clamp it again to the desired setting. Two manual levers are available that can be mounted on the left or right. While the “H0” model can be installed in different positions, the “HS” model can be welded on as desired, even at an axially bent angle to utilize the ergonomic position. A large array of U and side clamping arms are available.

The models of the new series are available with or without sensors. Colored LEDs reliably indicate the current status of the clamp: green means ready for operation; yellow and red indicate that the clamp is in open and closed position, respectively. In order to prevent damage, the sensors are divided into two parts: the sensors are in the clamp; the connector shell with the LEDs is accessible from the outside. The new series is designed for use in a temperature range from minus 13 deg F to 158 deg F (minus 25 deg C to 70 deg C). The maximum holding force is 960 ft-lb (1,300 Nm) for model 50 and 1330 ft-lb (1,800 Nm) for model 63. Both models can replace the series 82M-3E.

DE-STA-CO has also combined several individual product line catalogs into a single new easy-to-use resource for stamping press operators. The comprehensive new 290-page Press Room Catalog is designed to show customers all of the tooling, vacuum and gripping options for building efficient sheet metal press end effectors. It can be downloaded at here. For convenience, the electronic version features a navigable table of contents that allows users to move directly to any one of the more than 60 product categories in the document. To show customers some of the possible end effector tooling combinations that can be created using DE-STA-CO products, the Press Room Catalog features a new end effector application guide. The application guide includes examples of several tooling setups, each diagrammed to show all of the individual parts included on the tool and which applications or markets the tool is best suited for.

Photos, renderings and product numbers can be found throughout the Press Room Catalog. Additionally, some sections include detailed features and benefits to help customers make the right selections for their needs. The vacuum cup section, for instance, includes ratings that show which cups work best for differing material surface conditions.

DE-STA-CO, 1025 Doris Road, Auburn Hills, MI 48326, 248-836-6700, Fax: 248-836-6740, [email protected], www.destaco.com.