Cutting Tool Data Exchange is Now Public

CAM and PLM software users can now access and share tool classification, class drawings and pictures through the Generic Tool Catalog.

Posted: February 20, 2016

NTB Interstate University of Applied Sciences of Technology (Buchs,Switzerland), an institute that specializes in engineering informatics, has announced a new website (available by clicking here) that provides information to the public in the Generic Tool Catalog (GTC) cutting tool data exchange format.

This exchange format was developed through collaboration among machining hardware and software leaders Siemens PLM Software (Plano, TX), Sandvik Coromant (Fair Lawn, NJ), Iscar Ltd. (Tefen, Israel) and Kennametal Inc. (Latrobe, PA). It is available to all tool vendors and application developers enabling them to share cutting tool data more easily and precisely. GTC enhances the leading data exchange format, ISO 13399, and enables a direct connection between the tool vendor and the application without the need of an intermediary company. GTC formats catalogs from Sandvik Coromant, Iscar, Kennametal and other companies are currently being deployed into production by leading manufacturing companies.

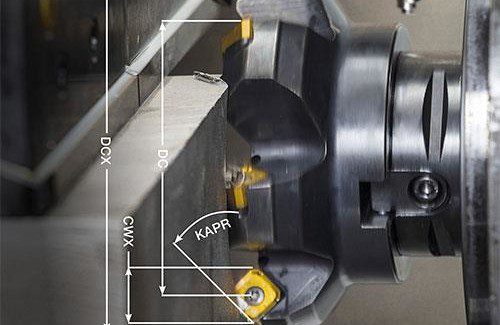

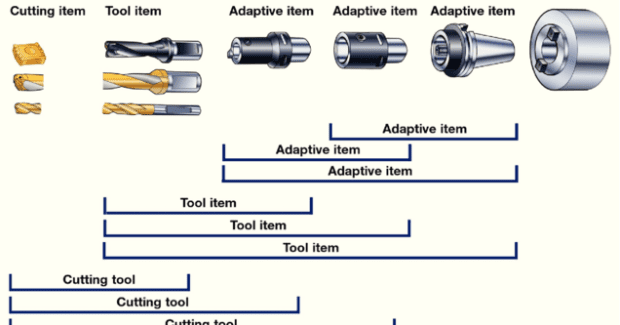

Having access to complete, reliable, comprehensive cutting tool data has been a need for computer-aided manufacturing (CAM) and product lifecycle management (PLM) software users for a very long time. ISO 13399, established by the International Standards Organization, created a common language for industrial product data, but there was also a need for additions to that information, such as tool classification, class drawings, and pictures. GTC makes this additional information available for use by cutting tool vendors and applications developers.

Siemens PLM Software’s Manufacturing Resource Library (MRL), part of its Teamcenter® software portfolio that provides classification and data management for manufacturing engineering resources, can import catalogs in GTC format. This enables the use of tool data and 3D models in the creation of tool assemblies that can be seamlessly used in Siemens’ NX™ software for tool assembly documentation and in NX CAM for tool path creation and simulation.

“This new web site makes information about GTC easily available to the general public,” said Marcel Keinan, the director of product management at Siemens PLM Software. “We are fully committed to GTC. It specifies a standard format suitable for application developers, and avoids the need to create interfaces for different cutting tool vendors and applications.”

Sandvik Coromant is one of the founders of ISO 13399 and provides catalogs in GTC format compliant with this standard. GTC is also supported in their Adveon™ tool library application, which interfaces to several CAM systems. “The GTC standard is a vital step forward for the communication needed in the current and future digital manufacturing environment, Industry 4.0,” says Per Nilsson, the senior manager of intelligent and digital machining at Sandvik Coromant.

Kennametal believes that shops should have access to tooling data in the software of their choice. In order to access essential cutting tool information within the design and manufacturing processes, the company is providing their customers with product catalogs in the GTC format. Kennametal relies on NOVO™ for its tool advisor and management application that will support the creation of GTC catalogs that can be imported into Siemens’ software.

“We believe in the future of digital manufacturing. Partnerships with companies like Siemens are critical to the success of improving the way work is getting done. Moving ahead with the GTC helps the manufacturing community by integrating our tooling information in the end-to-end product development processes,” says Fred Patterson, the vice president of product engineering and a founding member of ISO 13399.