Automating GD&T Principles and Practices Into Inspection

The advanced software in these new shop floor inspection systems integrates geometric dimensioning and tolerancing parameters into the measurement process to improve the assessment of functional precision in the parts being measured.

Posted: February 5, 2016

3D Inspection Software for Intuitive Contact and Non-Contact Measurement

VXinspect intuitive 3D inspection software from Creaform includes all of the tools for first article inspection and quality control.

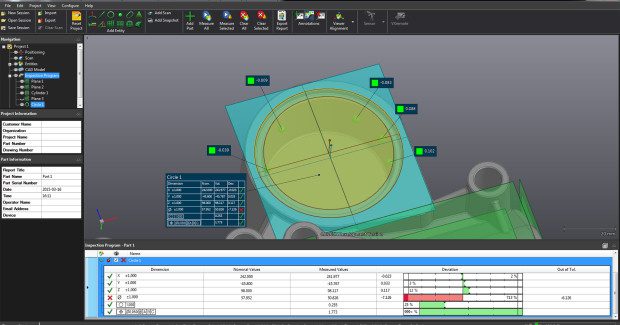

Automated Shop Floor Inspection System

The programmable CMM Master automated shop floor inspection system from Verisurf combines a complete coordinate measurement CAD system with 3D surface modeling, traditional 2D drafting and 3D model associative GD&T with the Equator comparative gauge.

Next Generation Coordinate Measuring Machine

The XM Series handheld probe coordinate measuring machine from Keyence easily installed in any environment to perform intuitive 3D measurements with high accuracy using advanced optics, image processing and structural design.