Grinding Gamma Titanium Aluminide

New grinding technology is being researched on this intermetallic to help lower the costs of manufacturing aerospace engine components, develop grinding expertise, and design custom-bonded abrasive and superabrasive grinding solutions that are ideal for efficient and damage-free grinding of components made of titanium aluminides.

Posted: January 8, 2016

Titanium aluminides possess many characteristics that make them very attractive for high-temperature structural applications in automotive and aerospace industries. Their high specific strength, high-temperature stability and oxidation resistance relative to conventional titanium and nickel alloys, make them beneficial for use in low-pressure turbine blades for aerospace engines, as well as turbochargers and exhaust values in automotive engines [1].

Titanium aluminides can vary in mechanical and thermal properties based on the annealing temperatures used in processing. Research has shown that among the four different γ-TiAl microstructures that can be obtained by annealing, the duplex microstructure, as shown in Figure 1 (containing between 45 atomic% and 50 atomic% aluminum), is more ductile at room temperatures than others. Therefore, this is the most commonly used microstructure for engineering applications. It consists of two constituents: the gamma (γ) phases which provide strength and the lamellar phases, with alternating layers of α2 and γ phases, which increase toughness.

Large scale applications of γ-TiAl in aerospace engines began with use of this duplex gamma titanium aluminide material, specifically GE 48Al-2Cr-2NB alloy (commonly designated 48-2-2), in the last two stages of the GEnx engine for the Boeing 787 Dreamliner, which entered service in 2011 [1]. Since then, γ-TiAl has found increasing acceptance among engine manufacturers for newer engines. Both the new Pratt and Whitney GTF engines and CFM Leap Engines have different stages composed of γ-TiAl blades in their low pressure turbine areas [2]. The heat resistance typically associated with nickel alloys, alongside the lightweight characteristics of titanium, make γ-TiAl attractive for these engine makers who are striving for increased fuel efficiency and reduced emissions.

Titanium aluminide components are generally very expensive to process and can be two times to three times the cost of nickel-based superalloys [3]. Near-gamma alloys are processed through ingot metallurgy, powder metallurgy or casting. The next steps in component fabrication are usually done through some form of machining, grinding, or by non-traditional methods such as electro-discharge machining, electro chemical machining or some combination of these processes. When compared with single-point machining, like with any intermetallic, grinding is often recognized as the best method for achieving final part dimensions and surface characteristics on γ-TiAl components [3].

We have been researching and developing new grinding technology to use with these intermetallics since 2011 at the state-of-the-art Higgins Grinding Technology Center (HGTC; Northboro, MA). Testing has been performed in close coordination with its European counterpart, European Grinding Technology Center (EGTC: Norderstedt, Germany), to meet the global manufacturing needs of the aerospace and automotive industries. The focus of this research is on developing grinding expertise while designing custom-bonded abrasive and superabrasive grinding solutions that are well-suited for efficient and damage-free grinding of components made of γ-TiAl.

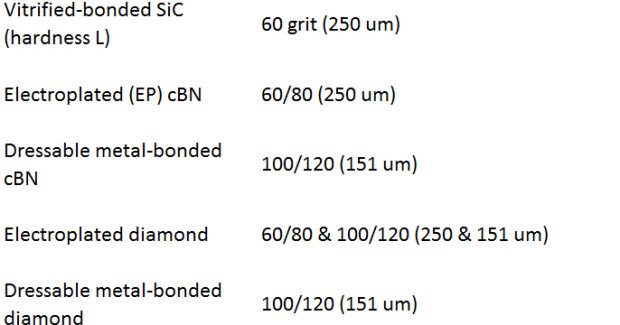

Recent product testing on gamma titanium aluminide focused around evaluating three core abrasive types: diamond, cubic boron nitride (cBN) and conventional silicon carbide (SiC). The diamond and cBN products included electroplated and dressable multi-layer metal bonded wheels, while the SiC abrasives were used with a conventional vitrified bond system. For each superabrasive type (i.e. diamond and cBN), two grit sizes were evaluated to better understand the effect of grit size on force, power, and surface finish of the final components. A summary of the wheels is shown in Table 1.

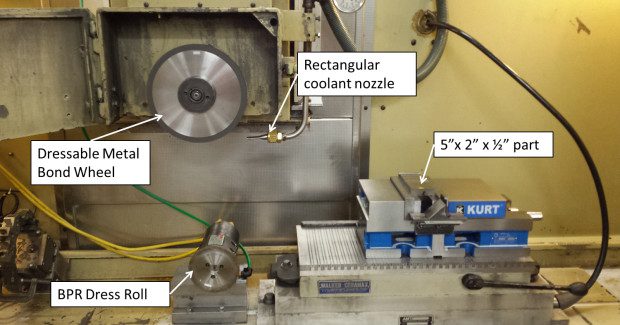

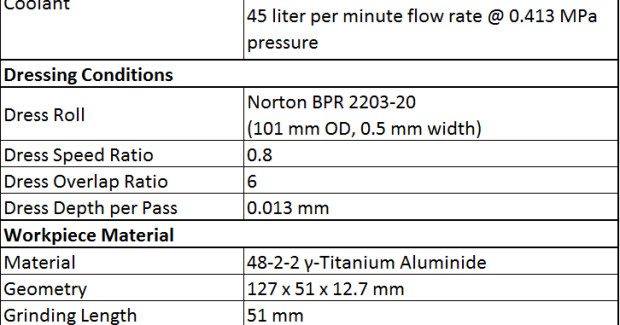

Testing was conducted by grinding slots (as shown in Figure 2) into blocks of gamma titanium aluminide under two material removal rates in order to evaluate the products in both mild and aggressive grinding conditions. Only one set of grinding conditions was used per slot, in order to preserve the ground surfaces for subsequent analysis. Wheels were dressed in between slots (i.e. for each new set of grinding conditions). A summary of the grinding conditions is shown in Table 2.

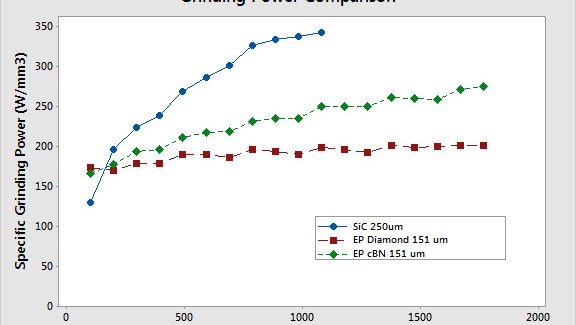

Products were evaluated based on power, applied normal forces, part surface finish, and damage in the titanium aluminide components (cracking and/or burn). The results of this study showed that for the conventional SiC abrasives, the power (and forces) increased as a function of stock removal (shown in Figure 3). Similar trends were also observed for cBN wheels; however, the power increase was much lower than for SiC. The diamond wheels drew the lowest power consistently, and also had the most stable power curve as a function of stock removed. The same trends were observed with the coarser superabrasive wheels (250 um) and the multi-layer superabrasive products relative to the SiC abrasive products.

The increase in power (and forces) in SiC wheels resulted in cracking and mild burn on the surfaces of the ground components (shown in Figure 4). No cracking was observed in the components when ground with the cBN or the diamond wheels after 1800 mm3 of material removal. In fact, the diamond wheels were capable of removing ~48000 mm3 of material without damaging the components. The cBN and SiC wheels reached only about 6 percent and 10 percent, respectively, of that total value before part damage was observed.

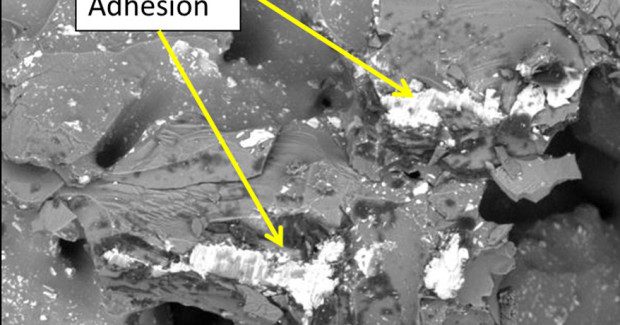

The damage in the components was attributed to metal adhesion on the tips of the grains. This adhesion is shown in Figure 5 and was most prevalent in the SiC wheels. This metal adhesion was also observed on cBN grains, but to a much lower degree than the SiC. Very little metal adhesion was observed on the tips of the diamond grains. The adhesion of the metal to the surfaces has been known to lead to lower grinding efficiency (i.e. higher frictional contributions and a reduced ability for the grains to remove material).

While the diamond products were clearly superior in terms of cumulative stock removal without component damage, individual grinding processes may still dictate the use of SiC products. Processes which require frequent wheel dressing in order to maintain strict form requirements would benefit from using SiC, as the cost per wheel is substantially lower, and form can be easily maintained through dressing. Electroplated diamond wheels, while capable of removing substantial amounts of material, are limited in their tolerances. If used to the point where the wheels come out of tolerance, no redressing can be done and the product must be replaced.

With the recent development of new, multi-layer dressable metal bond diamond products, new possibilities have been opened up with the ability to use these diamond products in applications where form and finish have very strict tolerances that can be maintained over time. The future of γ-TiAl as a prominent material in advanced aerospace engines is looking very promising. Newer technologies are constantly being pursued to bring the processing cost of γ-TiAl down to the levels of nickel-based superalloys. This will help to broaden the scope of γ-TiAl applications. For instance, some groups are successfully fabricating engine parts out of γ-TiAl using electron-beam based 3D printing [4]. Even these 3D printed γ-TiAl components will still require some form of grinding to generate the final surface.

With this in mind, we are continuously striving to provide innovative solutions to grind this material more efficiently to our aerospace customers and OEMs. Recent studies document some great advantages with the use of dressable metal-bonded diamond wheels with patented high-porosity (Norton Paradigm) for grinding γ-TiAl [5]. For those users that prefer conventional wheels instead of superabrasives, new and improved conventional SiC wheels that enable cooler cutting and require lower dressing frequency are also being pursued.

References

- C. Campbell, “Lightweight Materials-Understanding the Basics.”

- Aviation Week & Space Technology, “Pratt & Whitney’s Geared Turbofan Growth Plan,” July, 2013.

- Daniel Margolis, “Inter-metallic Wonder,” Cutting Tool Engineering, 57, 12, 2005.

- GE Reports, “This Electron Gun Builds Jet Engines,” April 17, 2014.

- Robin Bright, Andrew Biro, Mike Hitchiner, “Grinding of γ-Titanium aluminide with superabrasives,” 2015.

Andrew Biro is a research engineer and Philip Varghese is an advanced applications engineer at Saint-Gobain Abrasives Research & Development, 9 Goddard Road, Northborough, MA 01532, 508-351-7100, www.saint-gobain-northamerica.com.