CNC Axis Sharing Innovation

NUM has developed an innovative new CNC axis sharing facility that enables designers to create machine tools of unprecedented versatility and productivity.

Posted: January 4, 2016

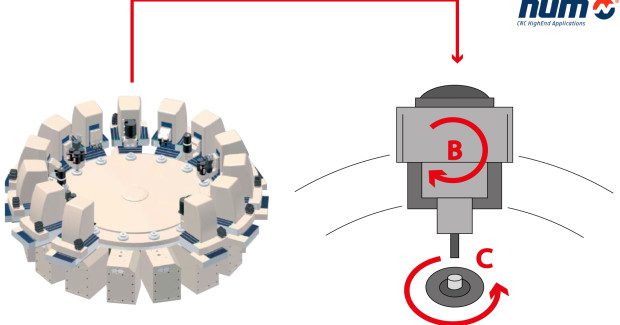

An innovative new CNC axis sharing facility has been developed by NUM Corporation (Naperville, IL) that enables designers to create machine tools of unprecedented versatility and productivity. Typical applications include multi-station production centers and rotary transfer machines with complex multi-role axis control requirements. The new axis sharing facility provides a very flexible and efficient means of controlling a large number of different groups of interrelated or synchronized motion axes by using advanced dynamic resource allocation techniques to share control across multiple CNC kernels. It further extends the flexibility of NUM’s high-end eight-channel Flexium+ 68 CNC architecture by allowing the control of up to 32 servo drives to be timeshared by any of the CNC kernels in the system.

NUM has a diminutive new servomotor and drive combination for small swivel heads that demonstrate the scalability of the Flexium+ CNC platform to suit virtually any level of machine tool complexity. This includes the new 40 mm frame size servomotor and drive combination for the swivel head axes of small machine tools, and a new 5 kW power supply for use with single-phase mains supplies. The Flexium+ CNC platform offers a choice of three configurations of CNC kernel, enabling machine designers to create cost- and performance-optimized control systems for a wide range of automation. The platform also provides an optional system-wide functional safety architecture, known as NUMsafe, which facilitates the implementation of safety functions for almost any type of machine tool, regardless of its complexity or number of axes.

The company also offers two new single-cable servomotors fitted with high resolution absolute digital encoders that are intended to help designers improve machine speed and efficiency by making maximum use of the inherent high bandwidth capabilities of Flexium+ CNC systems.

NUM Corporation, 603 East Diehl Road, Suite 115, Naperville, IL 60563, 630-505-7722, [email protected], www.num.com.