Is BIG-PLUS An International Standard?

Buyer Beware: This system has not been standardized by any governing body. If you purchase cheap dual contact tooling after being told by a supplier that it will work just as good as the original for half the price, you risk unsatisfactory performance and/or damage to very expensive spindles. Here’s why.

Posted: December 23, 2015

More and more, we are asked this fairly simple question from shops who want to purchase BIG-PLUS® dual contact tooling from sources other than us. One would certainly think that this must be the situation, given that more than 100 of the world’s top selling machine tool builders have adopted the BIG-PLUS spindle system as their own standard. The truthful answer to anyone who asks is that this system has not been standardized by any governing body such as ISO, DIN, JIS, or ASME.

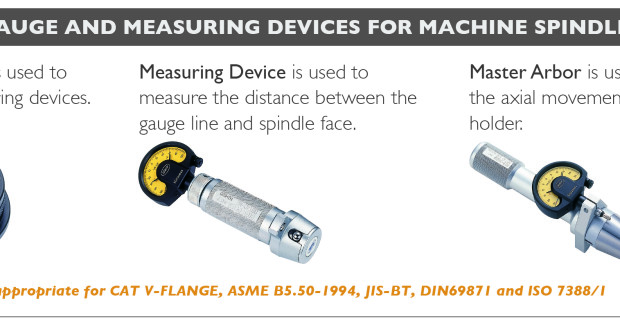

BIG Daishowa, the original developer of this system and a major reason that it has been so widely accepted throughout the world, still holds all of the proprietary information and, more importantly, the grand master gages that are used for reproducing spindles and tooling. Access to this information and gaging is well protected by BIG and is only provided to those companies who acquire a license agreement, mostly to protect the integrity of the system, which uses very close tolerances in order to function at its designed performance level.

The popularity of BIG-PLUS has surged over the past ten years as many shops have tried the system and have witnessed for themselves the huge benefits in higher performance and accuracy over standardized taper contact tooling systems, such as CAT or BT. Other dual contact systems, such as HSK, have also seen a rise in popularity for similar reasons, but perhaps not with all of the same benefits of BIG-PLUS. Unfortunately, all of this increased popularity and demand has been accompanied by a surge in unlicensed copies to the market that offer all kinds of promises and prices never seen before.

BUYER BEWARE

I cannot fault a shop for purchasing cheap dual contact tooling after being told by their supplier that it will work just as good as the originals for half the price. After all, human nature wants to find the best offer at the best price – that sort of deal is capitalism at its best. As consumers, we are all confronted with choices every day about buying similar products that do similar functions from a wide range of suppliers and costs. For me personally, I usually decide to buy cheap only when I know the product will be used one time and then thrown away. On all other purchases, I’m in it for the long haul and willing to pay higher prices. At the end of the day, I want to be confident I made the right choice for the long term, and I’m willing to pay more for my peace of mind.

Master gages for tooling are quite common. Generally all of them are traceable to a known master to compare the accuracy for rate of taper for production of tool holders, such as CAT or BT. ISO dual contact systems such as HSK rely on the use of a grand master gage that all other master gages are produced to, thereby guaranteeing that all HSK tool holders are the same everywhere in the world. Our company decided to find out how the world’s leading suppliers of HSK tool holders compared to the tolerances of the ISO standard. After acquiring more than 30 HSK-A63 taper tools from our competitors from all over the world and making a detailed quality inspection of the taper itself, we found that 50 percent of the samples were not in tolerance.

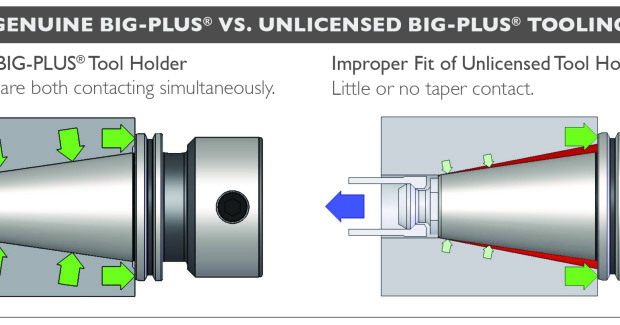

Perhaps the developers of HSK were overly critical of the functional limits and tolerances for the standard, given that 50 percent of most tools in use today are out of tolerance. In my opinion, this could be possible based on the very thin cross section of HSK tapers that allows for tool holders to expand elastically more than it was designed for. On the opposite side however, we have BIG-PLUS that relies on elastic deformation of the spindle, not the tool holder, therefore requiring a much stricter control of tolerances, even in comparison to HSK. This means anyone who is in the market for BIG-PLUS ‘dual contact tooling’ should also consider this simple statement: Only a licensed supplier of BIG-PLUS has master gages that are traceable to the BIG grand master gages and have the dimensions and tolerances provided to do it right. Everyone else is guessing and using a sample BIG-PLUS tool holder as their own master gage – a practice that any quality expert will advise against.

What are the consequences to a poorly researched choice in BIG-PLUS tooling? Unless all of the tools are marked “BIG-PLUS® Spindle System-License BIG DAISHOWA SEIKI,” the use of tooling not made by BIG Daishowa or its licensees may result in unsatisfactory performance and/or damage to very expensive spindles. Conditions producing such unsatisfactory performance include:

- Distance between flange face and gauge line diameter more than specification-little or no face contact occurs; tool holders provide only taper contact and no benefit of BIG-PLUS.

- Distance between flange face and gauge line diameter less than specification-face contact only; tool holders “float” in spindle taper with no positive radial location. Large cutter runout and fretting corrosion on spindle face occurs immediately. Severe spindle damage will occur.

- Gauge line diameter less than specification; face contact only with minimal or no taper contact. Severe spindle damage can occur.

- Gauge line diameter more than specification; taper contact only and no benefits of BIG-PLUS.

BIG Daishowa Seiki and its North American subsidiary, BIG KAISER, are manufacturers and distributors of original, licensed BIG-PLUS tooling. For a complete list of all licensed spindle and tool holder companies authorized for the production of BIG-PLUS, please contact us and remember: accept no substitutes.