The Real Cost of Missed or Defective Welds

The repercussions of missed or defective welds can reach much farther than jeopardizing part quality and disrupting welding productivity. How much risk is your shop willing to take?

Posted: November 6, 2015

Creating quality parts, maintaining high productivity levels and seeking ways to reduce costs are all critical factors in managing a successful welding operation. Missed or defective welds can jeopardize each of these goals, and depending on the size of the welding operation and the application, the repercussions can be far reaching. It’s important for shop owners and management to consider the level of opportunity for missed or defect welds in their welding operation. Some questions to consider:

- Does our company have complex parts that make them more prone to missed or defective welds?

- Can we validate that all welds are in place through simple visual inspection?

- How much risk is the business willing to take that the visual inspection is accurate?

- What would be the long-term consequences if a part fails for a customer?

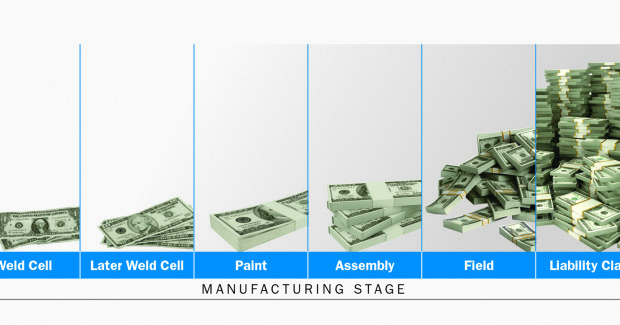

In certain cases, missed or defective welds can pose significant safety hazards, even leading to serious personal injury. They can also lead to staggering costs if the problem results in a failure in the field or in a liability claim. Not surprisingly, the earlier in the welding process that shops identify mistakes like these, the less costly it is to correct the problem. When everything is functioning properly in a welding operation and welding operators are creating quality welds, the cost of a typical welding operation can be broken down accordingly:

- Labor: 85 percent

- Filler metals: 6 percent

- Raw materials: 4 percent

- Shielding gas: 3 percent

- Electric power: 2 percent

However, when a missed or defective weld goes undetected, these costs escalate at every stage in the welding operation and beyond.

STAGE ONE: WELD CELL

Identifying a missed or defective weld in the weld cell is the ideal scenario. Welding operators can usually add the missed weld easily — and at minimal cost— and move the part to the next stage in the welding operation. Weld defects may be slightly more difficult to address. These require the removal of the weld and its rework, typically resulting in a cost of two to three times that of the original fabrication. Welding operations with smaller parts will be simpler and less expensive to inspect and rectify problems with in this stage than with larger components.

STAGE TWO: SUBSEQUENT WELD CELL

In operations with sub-assembly requirements, additional weld cells may be present to complete the production of the part. Identified missed or defective welds in this stage may need to be returned to the weld cell if a welding operator does not have the equipment or qualifications to make adjustments, resulting in several potential problems. If the part is large, the company may amass downtime for moving it, which can cause lost productivity and unnecessary costs. For companies that manage a lean, “just in time” welding operation, returning a part to the weld cell could also lead to a welding operator waiting on a part. Ultimately, the result is a bottleneck that affects the company’s throughput and profitability.

STAGE THREE: PAINT BOOTH

Missed or defective welds identified after painting will require a company to remove the paint, return it to the original weld cell and complete the previous steps in the welding process. These redundancies can cause companies to accrue cost not only for labor and rework, but also for the paint itself. For larger components requiring painting all at once, that cost could be significant.

STAGE FOUR: FINAL PRODUCT ASSEMBLY

If a company identifies missed or defective welds in this stage, it will require disassembling the part, removing paint and returning the part to the weld cell to be completely fabricated again. By starting the entire welding process over, costs continue to escalate due to both downtime and labor. In some instances, companies may be able to deploy a mobile welding cart to the production area to rectify the problem. Still, correcting a missed or defective weld in this manner requires additional labor for an employee dedicated to this purpose or potentially bringing in a welding operator from the weld cell to make the repair. The latter scenario prevents that employee from focusing on his or her own work in the initial stages of fabrication. Having a mobile welding cart also requires a capital investment for equipment that is only used periodically.

STAGE FIVE: DISTRIBUTOR OR CUSTOMER IDENTIFICATION

If a distributor identifies a missed or defective weld, a company could accumulate costs to remove the product and deliver a new one. In the case of a piece of heavy equipment, those costs could be substantial. The deployment of a mobile welding unit or repairs by a qualified person within the distributor network may also be an option, but are also costly. If a customer detects a problem with the finished product, it can lead to warranty claims in addition to having to remove and replace that item. The company’s brand reputation could be at risk, especially if the problem is reoccurring and becomes known throughout the industry. In some cases, tier suppliers who provide welded components to OEMs could potentially lose job contracts if they generate a poor track record for missed and/or defective welds.

STAGE SIX: LIABILITY CLAIM

Property damage or bodily injury is the most significant consequence of a missed or defective weld. This threat to safety is a very real concern and one that far exceeds the financial ramifications a company could experience as a result. Yet, there are still those financial concerns. Liability claims can generate significant expenses at this point. Negative — and potentially, permanent — damage to the company’s brand reputation is also possible and could lead to future loss of business and profits. Again, these effects are always secondary to a catastrophic event, but companies must consider them as due course of operating a successful business.

SOLUTION OPTIONS

For some companies, standard quality control inspections may be enough to protect against missed or defective welds. For example, welding operations with smaller, less complex parts may be easier to evaluate on an ongoing basis. Shops with larger and more complicated welding applications or parts, however, may find the need to implement redundant quality checks throughout the welding process, leading to higher labor costs. Such operations could benefit from alternative means of quality and cost assurance — advanced welding information management systems are one such option.

These systems electronically gather weld data to help companies drive quality and productivity improvements in the welding operation. Among other features, they also provide real-time feedback to the welding operator to help prevent missed or defective welds. Using a human-machine interface (HMI) located in the weld cell, the systems guide the welding operator through the correct weld sequence and placement though visual cues on screen (usually a PC monitor), counting each weld as it is completed. Welding operators must finish each weld correctly and in order before proceeding to the next one.

Advanced welding information management systems also monitor welding outputs to ensure that the welding operator is welding within the appropriate parameters to create a quality weld. They are capable of tracking multiple factors, including:

- Amperage and voltage

- Gas flow

- Wire feed speed

- Weld duration

Shops can program an advanced welding information management system to respond accordingly if a welding operator welds outside of an acceptable threshold. The system can provide a simple alert or it can disable the welding gun entirely until the proper personnel is able to identify the problem and offer a solution.

By monitoring weld sequence and parameters, a company that has chosen to invest in an advanced welding information management system — at the purchase price of approximately $1,000 to $3,000 — can help prevent productivity loss, product quality failure, liability claims or damage to its brand image that could otherwise cost hundreds to millions of dollars per event. When shops consider that upfront cost compared to the long-term benefits and savings of these systems, the investment — for the right company and the right application — makes good business sense.