New Cutting Edge Geometry for Stainless Steels

These special tools have been developed for increasing process reliability when machining problematic materials with higher ductility.

Posted: November 13, 2015

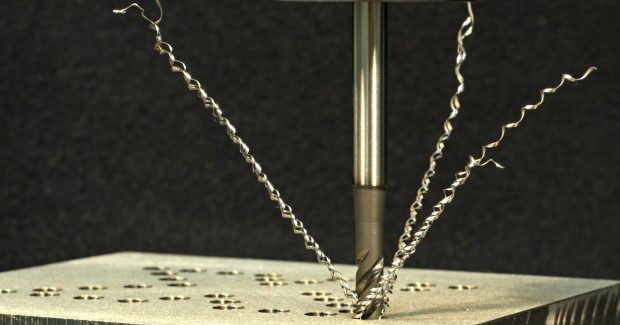

The properties of stainless steel, in particular its higher ductility compared to regular steels, are the reason why this material is difficult to machine. Due to these properties, even special tools tend to wear quickly. Furthermore, there is often considerable burr formation in milling operations so that the desired surface quality cannot be achieved. Now, with its XTOP series, WEXO Präzisionswerkzeuge GmbH (Bad Homburg, Germany) has developed special tools for these problematic materials that can increase process reliability in machining operations.

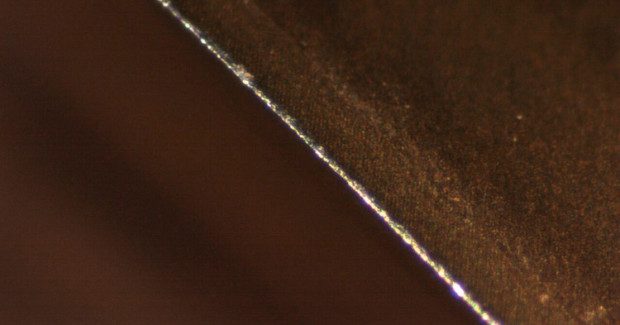

The cutting edge geometry and cutting parameters of the end mill, for example, have been optimized in such a way that, with Ra values of approx. 0.40 µm, a particularly high surface quality and nearly burr-free material edges are produced. The geometry of the tap with regard to chamfer and thread relief has been adapted in such a way that the torques generated during chamfering operations and at the reversal point are reduced. Also, in the case of deep blind hole threads up to 3xD, chips can be optimally guided and sheared off without any problems in reverse motion. The tools are also suited for Hastelloy or non-ferrous materials.

“To compensate for the high ductility of Inox, which is higher than that of regular steels, a special cutting edge geometry has been developed for the XTOP end mill to facilitate chip formation,” explains Björn Hamel, a product manager at WEXO. The end mill has unequal helix angles: the opposite cutting edges each have an angle of 39 resp. 41 deg. This makes the tool run much more smoothly than an equally helical tool, especially when milling pockets, and chip removal is improved. The end mill has a TiAlN-TiSiN coating that forms an extremely smooth surface with good sliding properties that facilitate the machining of the workpiece. Furthermore, the XTOP excels due to its particularly smooth running and very low wear. This prolongs the service life of the tool, as well as its productivity and process reliability.

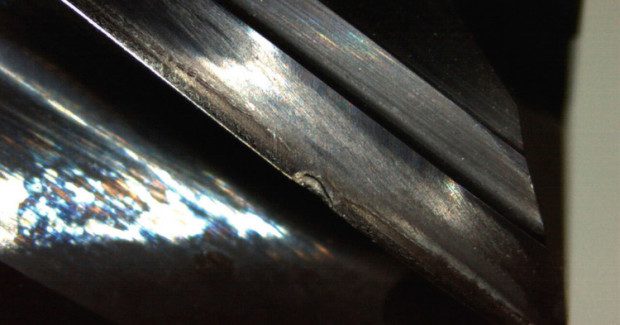

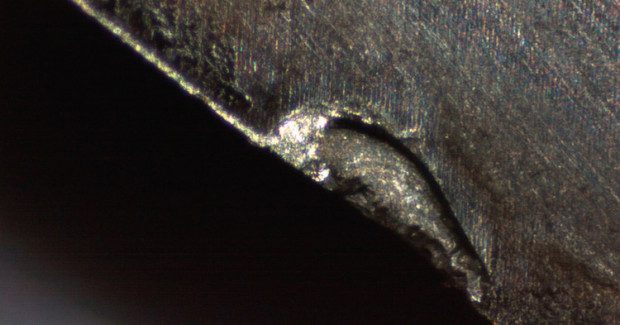

“The reason why stainless steel is so difficult to machine is that the basic strength of the material increases due to the heat generated when being machined. For example, when milling austenitic stainless steels and stainless duplex steels there is an increased risk of notch wear and chipping of the cutting edge due to micro cracks,” notes Hamel. To avoid this, the cutting edge geometry of the XTOP end mill has been designed in such a way that it counteracts this effect. Cutting parameters such as revolution speed, feed rate, infeed and cutting depth have been especially adapted to Inox in order to achieve a particularly high surface quality. In this way, an Ra value of 0.39 µm was achieved using the end mill in a finishing process on 1.4571 material.

SPECIAL THREAD RELIEF ON THE TAP

“When tapping into stainless steels, there is a high risk of breaking the tool due to jammed chips, especially when cutting blind holes,” adds Hamel. “In contrast to a through hole where the chips are removed forward, the chips are removed from the borehole against the cutting direction.” This is why the powder steel tap of the XTOP series has been designed with a new geometry to chamfer and thread relief in order to compensate for the higher toughness of stainless steels. “This facilitates the shearing off of the chips in reverse motion. Also, the torques generated during chamfering operations and at the reversal point have been reduced considerably,” continues Hamel.

The minimized friction has an overall positive effect on the surface quality and the accuracy to gauge and considerably increases the process reliability. The new tap also features a helix angle of 50 deg and an HL coating so that chips can be optimally guided und sheared off without any problems in reverse motion, even in the case of particularly deep blind hole threads. As noted earlier, this applies to thread depths of up to 3xD.

WEXO Präzisionswerkzeuge GmbH, Siemensstraße 13, 61352 Bad Homburg, Germany, +49 (0) 6172 1062-06, Fax: +49 (0) 6172 1062-13, [email protected], www.wexo.com.