How to 3D Print Precision Drills

The days when precision tools and additive manufacturing strategies could not co-exist are history.

Posted: November 13, 2015

“Manufacturing based on the hull/core principle is immensely important for us. First, the core of an insert drill is built with the cooling system, which is added to the conventional shaft. In a second additive run, the outer hull is built up with higher densities, which is close to the ideal for a good drill bit: hard outside and soft inside.” (Photo courtesy of Mapal)

For the first time, the precision tool specialists from Mapal Dr. Kress KG (Aalen, Germany) are printing drills with additive manufacturing, with amazing results from a new geometric freedom for designing complex parts. The company, which has 3,120 employees in Germany and 4,500 worldwide and reached €510 million in sales in 2014, manufactures roughly 95 percent of their precision tools for reaming, precision drilling, drilling, milling and turning in small and medium batch sizes down to 3-5 units. In the 65 years since it was founded in 1950, Mapal has continually reinvented itself as a think tank for high-tech drilling innovations in automotive, mechanical, tool and plant engineering. Now, in this new pioneering role, the company is using the LaserCUSING process from Concept Laser GmbH (Lichtenfels, Germany) to create additive tool solutions from metal powder using laser melting systems.

“We first explored the market on the supply side to evaluate different production system concepts for our applications,” recalls Dr. Dirk Sellmer, the head of research and development at Mapal. “We soon discovered how additive manufacturing would change our previous machining environment. Just 12 months after choosing the LaserCUSING technology, we put the first series-ready products on the table in the spring of 2014. Our boss, Dr. Dieter Kress, was so impressed that he often carries an additive part to show visitors this minor miracle.”

DRILL DESIGN REQUIREMENTS

High performance, long service lives and rapid tool changes are the central requirements for modern tool design. The QTD insert drill from Mapal excels at these through good chip deformation and reliable chip removal thanks to its geometry. The insert is held in a stable prism connection. These precision features make high cutting specifications and drill quality possible. Four types of QTD inserts are offered: for steel, stainless steel, cast iron and aluminum.

This insert drill was previously available in diameters of 13 mm and greater. One reason for this is the coolant supply in the tool body. The smaller the tool body, the greater the adverse effect of the standard central coolant supply on the tool’s performance. The central coolant supply weakens the core of the drill and makes it unstable. The cooling channels must also be ever smaller, which reduces the flow of coolant to the insert.

NEW SPIRAL COOLING FUNCTION

The new QTD insert drill is manufactured by additive laser melting in diameters from 8 mm to 32.75 mm with a new steel tool body design that has spiral cooling channels not usually used for small diameters. This new design allows even solid drills to be produced in the 8 mm to 12 mm diameter range. The design uses hybrid manufactured parts – the tool shank is machined conventionally and the drill is additive laser melted – for more economical manufacturing. “Hybrid strategies are the ideal method of choice,” notes Dr. Sellmer. “Simple component parts are machined and more complex areas are then built up additively.” Unmanned manufacturing and the reduction of tooling-up times and reworking in the digital laser melting approach are also more economical.

But the greatest advantage of transitioning from conventional to additive manufacturing was how it facilitated an entirely new geometry that increased the performance of the tools. “The additively manufactured insert drill uses a cooling concept with spiral ducts that improve cooling performance,” explains Dr. Sellmer. “Compared with the previous central coolant supply with Y diversion, a spiral coolant routing increases the coolant flow by 100 percent.” It also increases the core stability with coolant ducts that run parallel to the flute.

Cooling is also improved by the new coolant duct profiles that deviate from the usual circular form with a slightly triangular shape to optimize the geometrical moment of inertia and the flow rate. Tests found that choosing a cross section of this type increases the flow quantity by 30 percent. Coolant profiles like this cannot be produced conventionally. The coolant flows at a pressure of 1.6 bar to 3 bar. Overall, the new cooling function means better cooled drills are available for longer drilling tasks. It also allows expansion of the product range with smaller drill diameters.

HOW THE SYSTEM WORKS

“The ideal drill is very hard outside and somewhat flexible inside,” says Dr. Sellmer. “Laser melting makes it possible to generate selective thicknesses and then harden the surface with heat treatment and to create a cellular or honeycomb structure inside if necessary. This makes ductile lightweight solutions and e-modules possible, which we cannot produce conventionally. Manufacturing based on the hull/core principle is immensely important for us. First, the core of an insert drill is built with the cooling system, which is then added to the conventional shaft. In a second additive run, the outer hull is built up with higher densities. This is almost the perfect drill: hard on the outside and soft on the inside. We combine ductility with high tensile strength and hardness. The finished component is then vacuum hardened through heat treating.”

Stainless steel 1.2709 material is used. According to Dr. Sellmer, the powder requirement is calculated from the effective construction weights plus 10 percent, and the scrap material is easy to recycle. Internal tension in parts is critical for rotating tool solutions by Mapal. Tension must be removed from conventionally manufactured parts after machining due to the immense forces to which they are subjected. In the LaserCUSING additive process, the constantly changing exposure locations in the geometry internally remove the tension from the part during the build process.

Two M1 cusing systems are used with a central material supply container. From the medium performance range, these systems have a build envelope of 250 mm x 250 mm x 250 mm. The QTD insert drills are created as 10 x 10 unit or 11 x 11 unit solutions inside this build envelope so that 100 to 121 drills can be produced in one set-up. The build rates of the 400 W lasers are between 6 cm³/h and 18 cm³/h. In order to avoid contamination, the M1 cusing operates under a nitrogen protection gas atmosphere as usual. During processing, the laser heats the powder material to 60 deg C to 70 deg C for fusing. Thermal expansion in the build process must be considered in the design.

The new QTD insert drills have been such a success that market demand is now growing beyond the original 24/7 unmanned production capacity, so Mapal is considering options to increase additive production that include using multiple lasers in a system and/or a general expansion of capacity. Dr. Kress, the owner of the company, has mentioned a need for at least five systems in the medium term.

PRINTING INTELLIGENT, COMPLEX TOOLS

“Broadly speaking, the tools of the future will be more intelligent, more complex, and offer better performance,” states Dr. Sellmer. “New tool designs will result in new geometries with new performance features that would be inconceivable with conventional methods . . . but additive manufacturing facilitates all of these. Every additive project we implement teaches us how to approach future challenges. For example, besides optimizing part quality, we now prioritize process management to additively manufacture better surfaces closer to the precision component. In other cases, both cryogenic chip removal and market requests for closed cooling circuits and chambers have created new requirements for additive technology.”

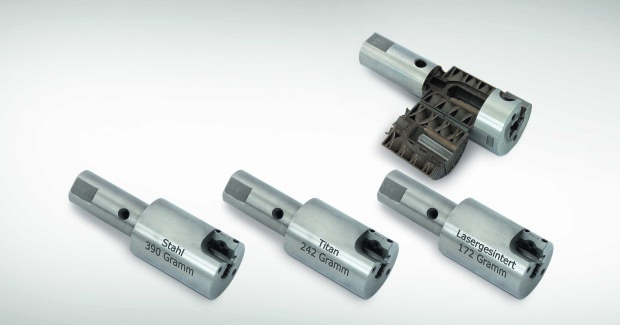

Additive manufacturing has driven design changes in the company’s new weight-optimized, laser-melted external reamers. The lighter the external reamers are, the better they work. This is particularly true for machining small-diameter shafts. Conventionally manufactured 8.5 mm steel external reamers already weigh 400 gm. This weight and the resulting mass inertia severely restrict maximum step speeds. Additive manufacturing allows lightweight external reamers to be built with integrated balancing potential. With conventional manufacturing, titanium would have been the choice alternative material for the external reamer, as opposed to steel, because it reduces the weight of the tool by approximately 35 percent. But titanium is expensive to buy, as well as difficult and expensive to machine. Instead, stainless steel 1.2709 is used because the density is evenly distributed in an external reamer.

“For these rotating tools, the weight and imbalances determine tool performance characteristics due to the mass inertia,” explains Dr. Sellmer. “External reamers manufactured additively can be roughly 50 percent lighter or more and can be made with internal cavities called balancing profiles that permit lower imbalances, higher speeds, higher precision and greater economy. This is based on a honeycomb structure that facilitates lightweight construction and balancing potential. Mass distribution of the honeycomb structure of the external reamers is like balancing wheels. The balancing profiles enable us to achieve virtually perfect concentricity of the rotating tools. In general, we assume that we can also optimize the honeycomb structure bionically. FEM analyses allow us to optimize these honeycomb structures to increase the rotating potentials. Our patent for solutions like this gave us the foundation we needed.”

He is referring to a patent-pending rib structure specially designed for the reaming application that reduces the “new” 8.5 mm external reamer weight to 172 gm – a weight saving of 57 percent that improves the performance of this rotating tool through faster machining and greater precision. “But this is not the end of the story,” adds Dr. Sellmer. “Process-appropriate design allows us to implement new ideas constantly as a work-in-progress.”

ADDITIVE INVESTMENT STRATEGY

“When making decisions like this, there was a lot to think about because all three main additive system providers offer good solutions on the hardware side,” states Dr. Sellmer. “However, certain nuances in the details can be important. For example, Concept Laser uses a special approach to topology that stands out in their stochastic control of the slice segments, also referred to as “islands,” which are processed successively. This exposure strategy induces the lowest tension in the component. They also offer open parameter intervention that is important for us in our R&D initiatives. Their M1 cusing system design is very customer-specific and easy to operate. This is not an “off the rack” system, but highly customized with a few soft factors.”

Was the investment a difficult decision for Mapal in terms of profitability? “It was the subject of debate that involved a certain amount of risk initially,” says Dr. Sellmer. “Dr. Kress is an owner who is highly interested in technology, but he also realized that something special happens when geometries are created from powder, as if by magic. The additive process has a special charm in unmanned manufacturing 24 hours a day, seven days a week. He also knew that our R&D staff would support an entrepreneurial decision to break new ground like this with a great deal of commitment. We defined specific goals and were given a lot of freedom when we went to work. Looking back, his decision was spot-on and points the way to the future.”

WHERE IT GOES FROM HERE

“This industry is highly conservative overall, which means innovations take a long time to catch on,” notes Dr. Sellmer. “But additive strategies shift the design principles towards product solutions that would have been inconceivable previously, with obvious positives for manufacturers and their customers. There is no other way to be successful in the future regarding manufacturing costs and the range of tool performance in quality, availability and unit pricing for users.”

He sees many new competitive strategies in the future with additive manufacturing. “Take retrofitting as one example,” says Dr. Sellmer. “An ISO tool has a certain number of lifecycles based on the workload in the user’s processes. This wear is normal. However, taking sustainability and resource saving into account, we have discovered that ISO tools do not have to be discarded because they still have potential for retrofitting. Additive structures offer many ways to restore the ISO tool surface to an as-new condition. Now that this new technology is available, we are checking all of our tools to assess the viability of design adjustments, which will lead to a range of new products and features.”

He also assumes that future developments in additive manufacturing assume that the build rates of laser melting systems will increase significantly. “Stronger lasers are not necessarily at the top of our wish list, as our parts are generally relatively delicate,” says Dr. Sellmer. “But I believe multi-laser technology would increase the performance and allow either faster or more selective processing, i.e., varying the layer thickness. The quality level will also increase. Together, this increases the economy and the performance parameters of parts.”

He also expects the range of materials available for additive processes to grow so that components can be adapted that are even better suited to their tasks in terms of performance or service life. Fundamentally, he envisions designing powder materials to optimally suit the process and application. “Our design options will also change,” adds Dr. Sellmer. “This will result in new geometries with new performance features. In general, additive manufacturing is ideally suited to increasing the imagination and creativity.”

Mapal Fabrik für Präzisionswerkzeuge Dr. Kress KG, Obere Bahnstraße, D-73431 Aalen, Germany, +49 73 61/5 85-0, [email protected], www.mapal.com.

Concept Laser GmbH, An der Zeil 8, 96215 Lichtenfels, Germany, +49 (0) 9571 1679-0, Fax: +49 (0) 9571 1679-499, www.concept-laser.de.