Standardized Machine Tool Controls Improve Production of Very Large Parts

This busy shop uses a common CNC platform to address the challenges of machining large parts and one-off runs for power generation equipment.

Posted: October 31, 2015

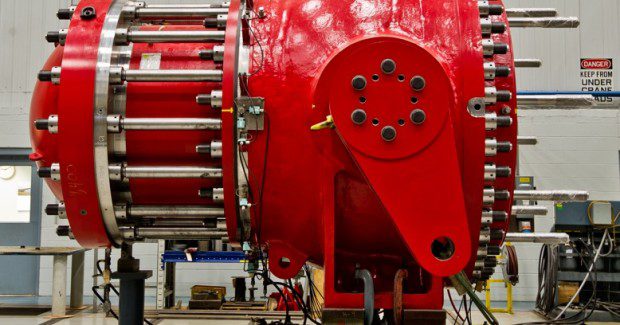

Voith Hydro Inc. (York, PA) is a major manufacturer of hydroelectric power generation equipment, especially the intricate turbines used in such operations that supply hydroelectric generating companies and municipalities throughout North America. Over 12,000 units have been commissioned in the field, with more than 65,000 MW of installed capacity, plus Voith has also upgraded over 600 existing power generation units. As a turnkey supplier to the industry that is is ISO 9001 and ISO 14001 certified, the company manages all phases of power plant projects, from analysis and planning, design and implementation, to commissioning and operation.

At the York facility, very large multi-axis machining centers produce carbon and stainless steel work pieces, most often in a one-off mode and at sizes frequently exceeding 35 ft diameter. The shop boasts machining capabilities on workpieces over 42 ft diameter and 350 tons. Surface finishes are typically 250 Ra and 125 Ra, though occasionally 64 Ra or 32 Ra is required. The finishes are achieved through both machining and secondary finishing operations, according to company sources.

Adam Ward, the manager of maintenance and facilities at Voith Hydro, says the machining done typically holds ±0.002 in tolerances here, nonetheless. “We do turning, line boring and milling on extremely large and heavy work pieces that often challenge us to design the optimum machining cycle. Our long cycles can frequently result in heat distortion on material surfaces and so we take great care in looking for problems before they occur.”

Voith Hydro maintains an impressive array of machine tools and multi-axis machining centers here. Despite a variety of builder brands, the majority of the machines have one common component, namely, the Siemens Sinumerik 840D CNC onboard. As Ward notes, “Our operators are quite comfortable with this CNC and they use it for all motion control, plus the operator interface has the ability to afford us great troubleshooting capability and something else we value greatly, the commonality of the HMI on the control. That fact allows us to do a great deal of cross-training and that’s very important to us. We need to be highly flexible, given the one-off nature of our work here.”

Most of the operators at Voith Hydro are capable of running multiple machines, while the maintenance personnel on his team can more easily service the machining equipment in the facility, adds Ward. He credits his machine builders and the Siemens team, led by Howard Weinstein, the business development manager for the power industry manufacturing sector at Siemens, and Robert Stiefel, for this ongoing flexibility.

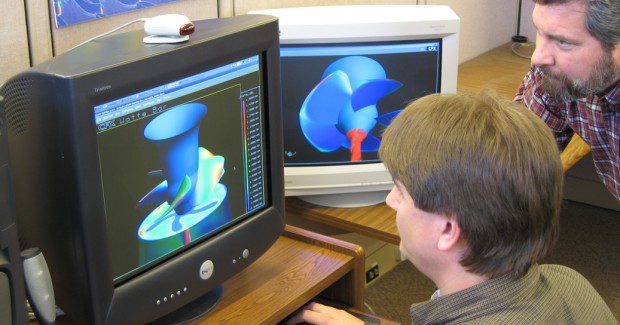

Voith typically takes a customer design, runs it through their CAM system and simulates the cycle offline, in order to preserve valuable machine uptime. Since the work here involves highly complex geometries on the turbine sections, the simulation must be equally complex and account for all machine motions and collision avoidance. Once the program is finally determined for a part, it is fed over the Voith Hydro network to the appropriate machine tool or machining center for scheduling and production startup.

During production, a system of real-time remote condition monitoring is available through the CNC for troubleshooting by both the Voith Hydro maintenance personnel and, when required, machine builder personnel, working offsite. Ward cites one example where an Ingersoll milling machine was completely retrofitted both mechanically and electrically by a Siemens Solution Partner, with a new CNC, motors, drives, encoders, other hardware and software. “Working with the builder and their support personnel, we were able to resolve issues and implement changes to the programming, right on the CNC of the machine . . . and all done remotely, in a very short time period.”

https://youtu.be/FyTMLmQuvY0

Ward further notes that, on most new machines required at Voith Hydro, “The cross-training capability of the CNC, the standardization of the HMI on various types of machines, the support provided and the previous successes our operators and maintenance personnel have realized, all combine to make specifying Siemens as our control of choice an easy decision.”

Weinstein comments on the relationship with Voith, “We’re a proud partner to them in York. Their facility is a great showcase for our Sinumerik 840D as a flagship CNC used on an array of multi-axis machining centers to produce large, complex geometry parts for the hydroelectric power industry.”

Voith Hydro Inc., 760 East Berlin Road, York, PA 17408-8701, 717-792-7512, [email protected], www.voith.com.

Siemens Industry, Inc., Drive Technologies — Motion Control (Machine Tool), 390 Kent Avenue, Elk Grove Village, IL 60007, 847-640-1595, Fax: 847-437-0784, [email protected], www.usa.siemens.com/cnc.