Soft Wired: Cutting High Taper Angles with Wire EDM

The ability to accurately and efficiently machine taper cuts using soft wire has opened up new areas of opportunity for moldmakers in aerospace, medical, electronics and other applications. Here are some ways to overcome the challenges faced when cutting high taper angles.

Posted: October 5, 2015

Wire EDM can successfully cut high taper angles that conventional machining processes cannot, but mold makers using wire EDM technology still face challenges when cutting high taper angles of 10 deg to 45 deg. Often EDM machines have the axis movement necessary to achieve the desired angle, but the physical properties of the wire and related machine technology may not be adequate. Examining the wire’s properties is useful in determining the right wire for achieving the best cut.

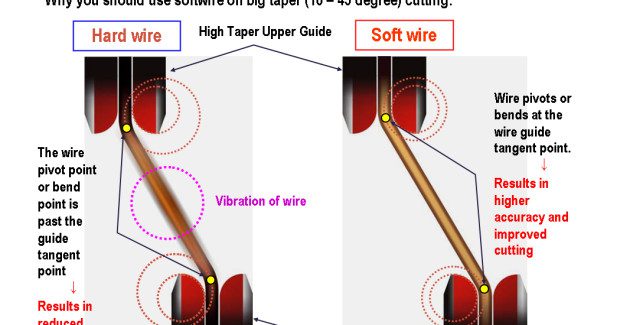

Hard wire is stronger, straighter and more resistant to breakage during cutting. High tensile strength, harder wire can better fight deflection during cutting, but very hard wire with little elongation can cause vibrations during taper cutting as the wire travels between the upper and lower wire guides. In addition, hard wire’s “memory” resists the true programmed wire path during high-taper cutting, which bends the wire and can lead to reduced accuracy, poor surface finish or wire breakage, which leaves intolerable marks on the workpiece and wastes material and production time.

A better solution for cutting high tapers is soft wire. Low tensile strength soft wire easily bends to follow the correct path determined by the CNC controller to provide more accurate cuts. However, soft wire has less memory than hard wire and is prone to breakage in aggressive cutting conditions. It is also sensitive to the voltages and tension applied to it by the EDM machine during the automatic wire feed (AWF) cutting cycle. If not handled properly, the result is a malformed wire tip which is curved, preventing the wire from being able to be inserted into the wire guides. In these instances, the machine is unable to thread or re-thread the wire so the erosion process is stopped and production time is lost. The operator is required to manually intervene before cutting can begin again.

OVERCOMING SOFT WIRE THREADING OBSTACLES

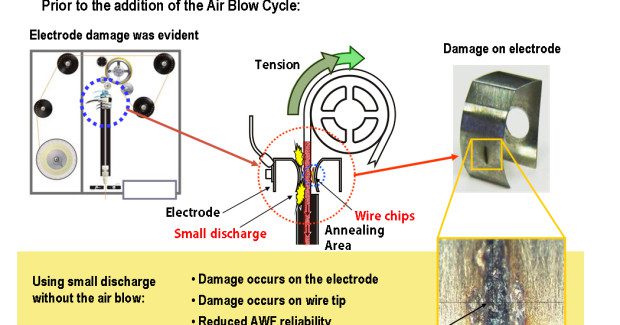

To overcome the challenges of soft wire threading, consider EDM equipment that provides improved wire processing during the AWF cutting cycle. Technology should include a way to precisely control the wire tension and energy used to cut the wire. The ideal AWF situation is one where the wire heats and stretches until it breaks in two without melting. Using the ideal voltage needed to cut the wire and form a bullet point can enhance soft wire threading performance, improving the straightness of the wire, and decreasing electrode wear.

It is not just the “hardness” or “softness” of the wire that needs to be considered. Factors such as the wire diameter, cutting and anneal tension and voltage need to be fine-tuned based on the wire selection in order to preserve the shape of the wire tip, minimize damage to the face and maximize straightness.

The small discharges used in wire EDM can result in damage to the electrode, damage to the wire tip, wire chip buildup and reduced AWF reliability. Some EDM machines now offer an “air blow” system, a unit that directs cool air to the wire cut point, which keeps the wire tip as cool as possible and prevents a molten tip to be produced during a thermal wire cutting process. To optimize the threading cutting cycle, a relay on a timer is used to open an air solenoid to gently blow cool air onto the wire cutting electrode, keeping the wire tip from heating up to a melting stage. This prohibits wire chip build up, extends the life of the electrode and provides reliable threading and cutting performance.

Accurately controlling wire tension is critical, especially with soft wire, during the cutting phase. An AWF system that includes a wire tension monitoring device providing continuous observation is important. EDM systems that include a dual AC motor and encoder wire drive system working in tandem, enabling the tension motor and drive roller to communicate energy usage to the controller, will allow the operator to better maintain wire tension throughout the cutting process.

The operator can take some measures to improve cutting performance. When working with soft wire, it is important to use a die guide designed for large taper cutting, especially if you are going to skim cut the large tapers to improve surface finish and accuracy. These guides have a much larger support to help the wire transition thru the large angles. In addition, to ensure accuracy, use the features in the CNC that compensate for the changing position (in Z-Axis direction) so that the taper angles are precise. Finally, if the cutting technology being used was developed for hard brass wire, the wire tension will have to be reduced on the rough cut.

Technical Specifications: Soft Wire vs. Hard Brass Wire

- Wire strength or hardness is usually measured in N/mm² (newton meters)

- EDM wire is classified as hard wire when the tensile strength = or > 900N/mm²

- EDM wire is classified as half hard wire when the tensile strength ~ 750N/mm²

- EDM wire is classified as soft wire when the tensile strength = or < 500N/mm² (Note: half hard wire is classified differently in Europe)

APPLICATIONS FOR SOFT WIRE EDM

Many technology developments in the EDM arena have changed the scope of EDM machining across aerospace, medical, electronics and other applications. The ability to accurately and efficiently machine taper cuts using soft wire has opened up new areas of opportunity for the technology. For instance, the medical industry regularly requires parts with steep angles. Surgeons depend on the accuracy of the angle to ensure proper placement of components in patients. The more accurate and smoother the finish, the less additional, time-consuming fitment the surgeon needs to do. Also, the longer a patient is open during surgery, the more chance there is for infection. Accurate parts/tools facilitate shorter procedures, resulting in quicker recoveries, which lowers costs across our healthcare system.

In the aerospace industry, expensive broaches are used to machine angled slots in rotors. Now many of the slots can be machined by tapering the wire and accurately holding size. Moldmakers in North America are now seeing the return of tight tolerance mold manufacturing from overseas. Using EDM for accurate and fine finishes on high taper surfaces allows extrusion mold builders to design molds, even with complex shapes, that flow. Because extrusions are gaining popularity, there is a constant need to improve strength and reduce weight to save energy. Molds that flow better have several advantages, including reducing electrical costs for the extruders and producing forms which have thinner yet stronger walls. The latter make the parts more adaptable to new technologies such as computer hardware and telecommunications components.

The ability to burn the prototypes with wire EDM that is capable of high tapering is pivotal for bringing these new products to market.