One Economical Machine for Every Application

Bug-O will showcase its lower profile 4th generation of the GO-FER IV, a straight-line, versatile and robust tractor that is extremely portable for all of a shop’s cutting and welding needs.

Posted: October 4, 2015

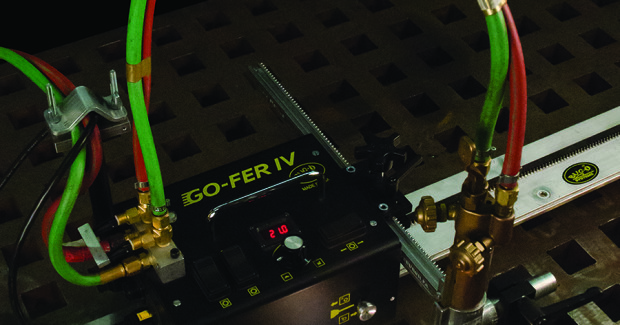

In Booth N-8013, Bug-O Systems Inc. (Canonsburg, PA) will showcase its lower profile 4th generation of the GO-FER IV, a straight-line, versatile and robust tractor that is extremely portable for all of a shop’s cutting and welding needs. In the past it took three machines to work in all the applications that the new GO-FER IV can perform. This is like having three units in one. Distributors and customers alike will enjoy the benefits that this one machine can perform because it reduces the need to stock and keep multiple machines and accessories on hand. This machine was designed from the ground up to meet all of the industries’ needs by incorporating a wide range speed motor (2.5 ipm to 100 ipm) and a large and bright digital speed meter. The meter can be preset ahead of time. It easily monitors your travel speed for all your processes. Additionally, with its built-in dual contactor switches, gas manifold and its flexible racking groups all standard, you are capable of cutting with oxy fuel or your plasma system. Shops can even perform precise quality gouging with the plasma system.

When utilized for straight line cuts and beveling with an oxy fuel torch, this unit has everything built in that a shop requires except the torch itself. The torch holder will accept any standard 1-3/8 in (35 mm) diameter machine torch with a 32 pitch gear rack. The quick-action gas manifold mounted to the rear of the machine is used as a strain reliever for the torch and also gives the operator the ability to turn on and off the gases without having to readjust the gas flow of the torch. Due to the broad travel speed range and its direct rack and pinion drive, the GO-FER IV is perfectly designed to work in conjunction with a plasma cutting system. Additionally, with the built-in trigger contactor for initiating the cut, it’s able to make straight plasma cuts and bevels. Furthermore, if you angle the plasma torch you can also perform precise mechanized gouging without changing machines.

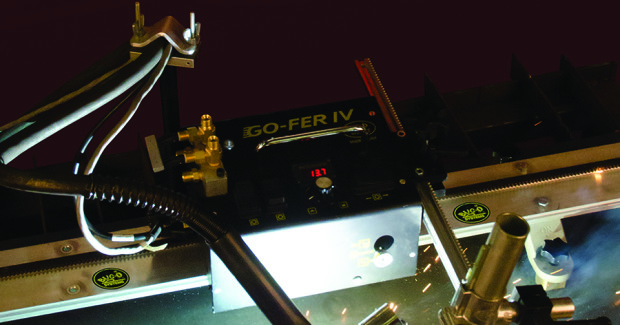

The GO-FER IV is proudly built in the U.S. and is backed by a three-year warranty so a shop can work with confidence knowing that the quality went in before the name was put on this industry proven machine. For example, the machine is designed and built for long service life and safety in the field as it incorporates a chrome moly pinion drive gear and the motor will lock in place if power is interrupted to the unit, even if it is being use in the vertical up position.

The optional Welding Kit (GOF-3255) provides everything a shop needs, including the fits-all clamp which will accept and accommodate any hand-held welding gun and allow the operator to position the gun at any angle they desire. The racking group allows for in process torch adjustment of the vertical and horizontal plane. The built-in trigger contactor allows the operator to activate the wire feeder from the switch on the top of the unit. Other options available include a 3-hose manifold and dual racking groups as well as limit switches for both ends to automatically stop the unit at the end of travel. Further options include a radius cutting attachment that enables this machine to be quickly changed from a straight-line to a circle cutting machine ranging from 8 in to 96 in diameters.

The GO-FER IV runs on heavy duty rigid aluminum rail utilizing patented On/Off magnets which are the strongest in the industry. When ordering the GO-FER IV Kit (4000), standard delivery includes one 8 ft rigid aluminum rail, two On/Off Magnets and two spacers, making this the most complete system ever.

Since 1948, Bug-O Systems has been proudly manufacturing in the U.S. powerful solutions for all of a shop’s cutting and welding needs, back by the only 3-year warranty for these types of products in the industry. Coupled with its vast distribution network in over 150 counties and its expansive product line, Bug-O Systems is the obvious partner for welding business, with equipment for straight-line cutting and welding, fillet welders, circle burners and welding machines, saddle and elbow cutters, systems of overlays, shape machines and systems for pipe welding. More well known is the Modular Drive System (MDS), a powerful machine that allows the operator to custom configuring one machine for a multitude of application. All of these products can be easily coupled with virtually any cutting and welding power sources and systems that are available today.

BUG-O Systems Inc., 161 Hillpointe Drive, Canonsburg, PA 15317, 412-331-1776, www.bugo.com.