Next Generation Laser Technologies

Coherent will display an array of laser technologies, ranging from 150W to 1,000W sealed CO2 lasers to multi-kilowatt fiber lasers.

Posted: October 28, 2015

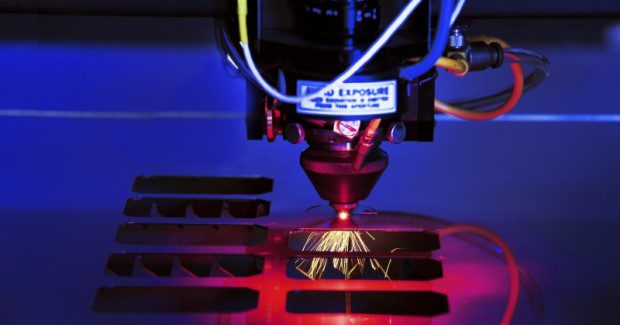

In Booth S-1992, Coherent Inc. (Santa Clara, CA) will display an array of laser technologies, ranging from 150W to 1,000W sealed CO2 lasers to multi-kilowatt fiber lasers. This spectrum of laser cutting tools all offer unique characteristics designed to present shops with versatile capabilities with distinct advantages in areas the market has identified as differentiating. Live cutting of metal material will be performed with a CO2 Laser Machine Tool operating at 1,000W. This versatile machine is capable of cutting both metals and organics, and is a highly productive tool that helps both job shops and dedicated application customers achieve high quality performance at a fraction of the cost of larger lasers. Capable of both raster and vector cutting, these workhorse machines are offered today in a range from 250W through 1,000W and can cut substrates as large as 4 ft x 4 ft (with optional methods to achieve larger length substrates). Productivity enhancement options are also available, such as:

- Machine vision system for fiducial alignment of substrates for very repeatable tolerance parts.

- Automated material handling to minimize time between sheet processing – this can increase output in many cases by as much as 50 percent.

New products coming out in 2016 include:

- 9.4 µm versions of the lower powered lasers for film material processing such as polyimide.

- A new launch of a Laser Machine Tool with a 150W CO2 laser geared for thinner material cutting at a lower cost of acquisition

- New program and nesting software that will increase file type flexibility

- New cutting head designs that will enable existing platforms to process a wider range of materials than previously possible.

- Upgrade, consumable, advanced training, and service offerings aimed at improving customer experience over the life of the ownership of the tool.

The company will also present at the FABTECH Conference Sessions regarding the range of cutting applications by process type, including reference to determining the right tool for a shop. This will highlight both their applications capability and include reference to both their CO2 and fiber technology. The presentation will be part of session F80 (“Innovations in Industrial System Technology I”) and will take place on November 11 at 10:30 am.

In recent years fiber lasers have become an established tool for cutting and welding of sheet metal. Coherent has developed a next generation fiber laser which is based on a modular and flexible architecture and will present its first products of the multi-kW modular fiber laser platform with power levels up to 6 kW. A 3 kW version, the HighLight 3000FL in a tall cabinet, will be on display. Lasers with 1 kW to 1.5 kW in output power will be available in a smaller cabinet. The laser is housed in an industrial IP54/NEMA 12 cabinet which can be equipped with an optional air conditioner and beam sharing / switching device. The laser consists of individual laser modules, which contain field-proven pump diodes and proprietary non-photo darkening active fiber.

The diodes, fibers and optics are designed and manufactured in-house. This vertical integration enables Coherent to design components such that the final product is delivering optimal performance and reliability at minimal cost of ownership. The modules deliver 1 kW to 1.5kW each, which are combined using a proprietary optical combiner. HighLight FL lasers at all power levels are available with a range of output delivery fiber options optimized for cutting and welding of a broad spectrum of metals and alloys and is covered by an industry-first BRIGHT warranty. This Back Reflection Immunity Guarantee provides assurance of Higher Throughput and lower cost. The company has tested the immunity by processing of copper or brass out of focus. The tests have proven the laser insensitive to back reflections, no negative impact on the process or laser lifetime could be observed.

The top racks of the cabinets house the control electronics of the laser and the high reliability DC power supplies. The laser can be controlled with most industrial I/O configurations including analog and Ethernet interfaces, and it also supports most bus communication protocols. This multi-kW fiber laser platform is ideal for cutting mild and stainless steel, copper, brass and aluminum with excellent quality. It is designed for field serviceability. The modular architecture and remote diagnostics, combined with a factory service training program and worldwide support infrastructure, enables OEM customers to directly provide service to their end customers. The company’s experienced global logistics and service network supports customers with remote warehouses and trained field service engineers all over the world. They enable quick turnaround of parts and reduced down time, even in countries with very complex import and export regulations.

Coherent Inc., 5100 Patrick Henry Drive, Santa Clara, CA 95054-1112, 408-764-4000, www.coherent.com.